A long-term prediction method for converter gas counters in metallurgical enterprises based on particle size calculation

A converter gas and prediction method technology is applied in the information field to achieve the effects of expanding the analysis range, perfecting the model, and ensuring real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

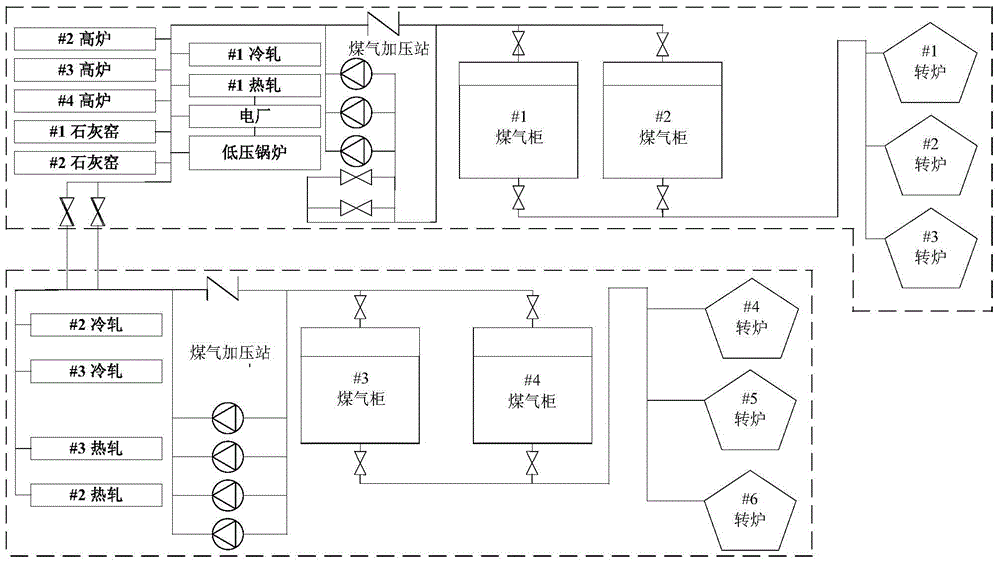

[0025] In order to better understand the technical solution and specific implementation of the present invention, the converter gas system of a steel plant with a relatively high level of automation in the domestic metallurgical industry is taken as an example for further description. attached by figure 1 From the schematic diagram of the converter gas system shown, it can be seen that the system contains six converters as generating units, as well as many consumption units such as blast furnaces, cold and hot rolling, and sintering, as well as low-pressure boilers and thermoelectric units as adjustable units. The cabinet acts as a buffer, which can temporarily store excess converter gas when the amount of converter gas generated is greater than the consumption, or temporarily supply the consumption unit to ensure production when the generated amount is insufficient. In addition, there are gas mixing stations and gas pressurization stations, etc. Transmission and distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com