Surface-coated modified lithium-ion battery positive electrode material and preparation method thereof

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor electron/ion conductance, unfavorable lithium ion redox reaction, and limited lattice stability, etc., to achieve high Good voltage withstand capability, lattice oxygen release problem, beneficial effect on cycle life and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

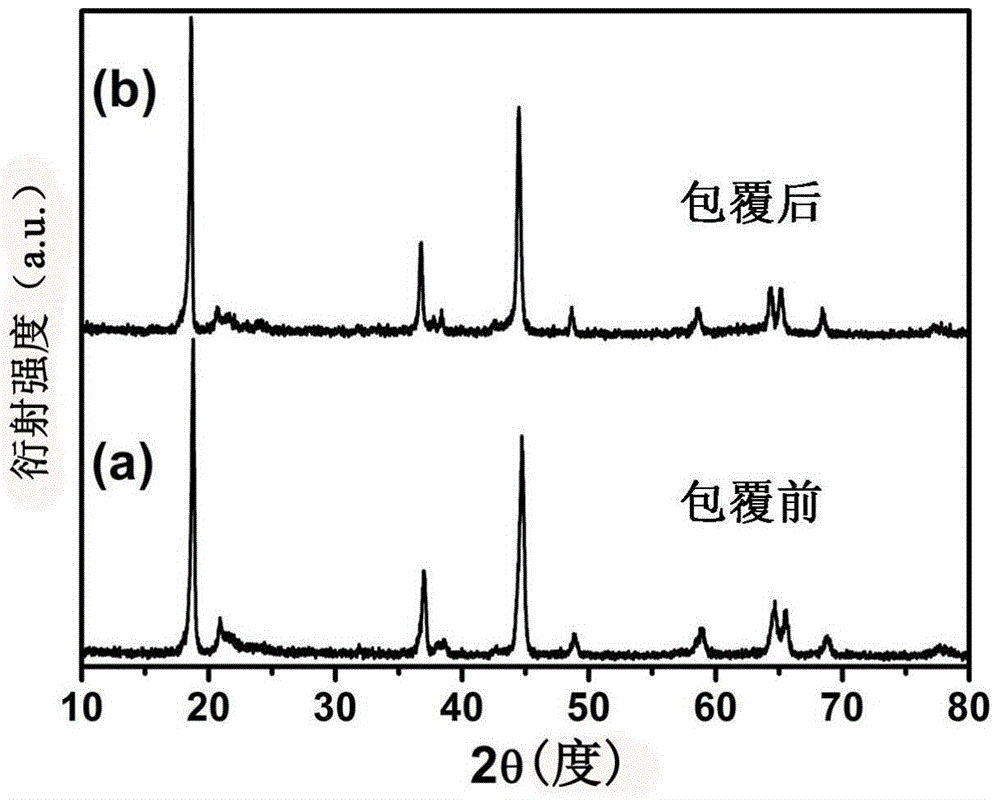

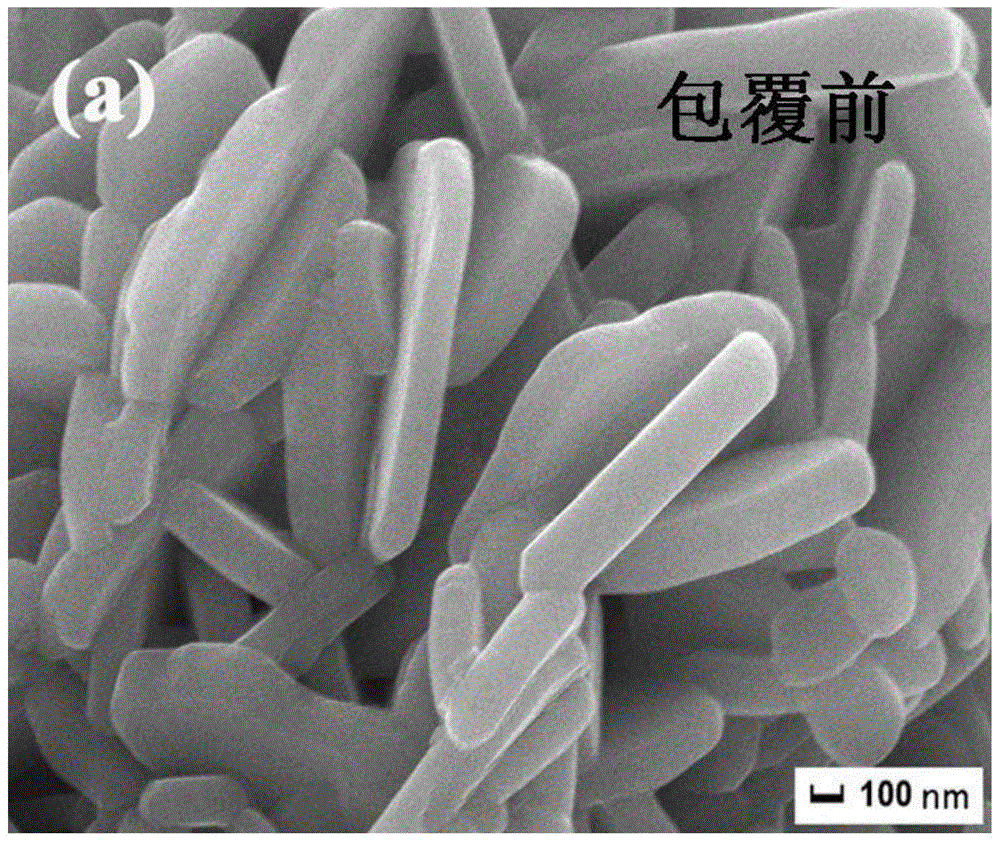

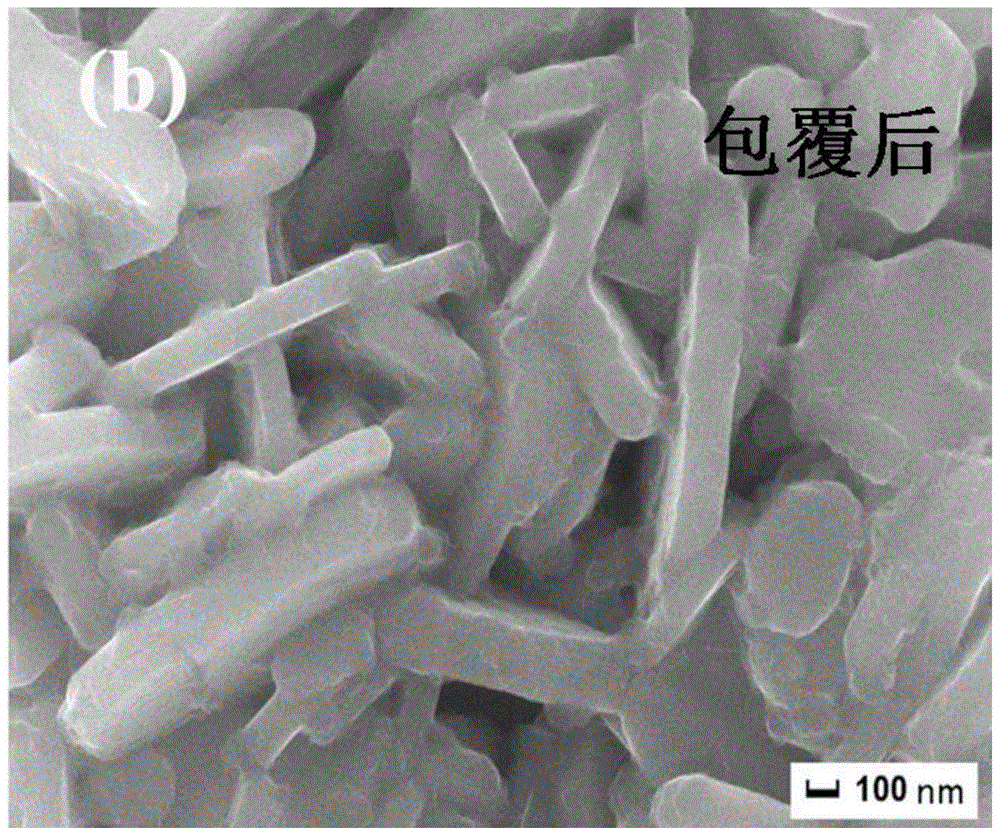

[0036] A surface-coated modified lithium-ion battery positive electrode material of the present invention, which is a core-shell structure, and the core is mainly a lithium-ion battery positive electrode material - a nano-sheet structure lithium-rich manganese material Li 1.2 mn 0.6 Ni 0.2 o 2 , the outer core is coated with Li 3 V 2 (PO 4 ) 3 A coated modified composite material composed of carbon materials, the quality of the coated modified composite material is 3% of the mass of the positive electrode material of the lithium ion battery in the core, wherein, Li 3 V 2 (PO 4 ) 3 The mass fraction in the coating modified composite material is 90%, and the mass fraction of carbon material in the coated modified composite material is 10%.

[0037] In this embodiment, the preparation method of the above-mentioned surface-coated modified lithium-ion battery positive electrode material specifically includes the following steps:

[0038] (1) Weigh 1.0507g of citric acid m...

Embodiment 2

[0044] A surface-coated and modified lithium-ion battery positive electrode material of the present invention, which is a core-shell structure, and the inner core is mainly lithium-ion battery positive electrode material - ternary material LiMn 1 / 3 Ni 1 / 3 co 1 / 3 o 2 , the outer core is coated with Li 3 V 2 (PO 4 ) 3 , carbon materials and carbon nanotubes are composed of coated modified composite materials, and the quality of coated modified composite materials is 10% of the mass of lithium-ion battery cathode materials in the core, wherein Li 3 V 2 (PO 4 ) 3 The mass fraction in the coated modified composite material is 80%, the mass fraction of carbon materials in the coated modified composite material is 15%, and the mass fraction of carbon nanotubes in the coated modified composite material is 5%. .

[0045] In this embodiment, the preparation method of the above-mentioned surface-coated modified lithium-ion battery positive electrode material specifically includ...

Embodiment 3

[0052]A surface-coated and modified lithium-ion battery positive electrode material of the present invention, which is a core-shell structure, and the inner core is mainly lithium-ion battery positive electrode material—LiCoO 2 , the outer core is coated with Li 3 V 2 (PO 4 ) 3 , a coated modified composite material composed of carbon materials and graphene, the quality of the coated modified composite material is 15% of the mass of the positive electrode material of the lithium ion battery in the core, wherein, Li 3 V 2 (PO 4 ) 3 The mass fraction in the coating modified composite material is 85%, the mass fraction of carbon material in the coated modified composite material is 10%, and the mass fraction of graphene in the coated modified composite material is 5%.

[0053] In this embodiment, the preparation method of the above-mentioned surface-coated modified lithium-ion battery positive electrode material specifically includes the following steps:

[0054] (1) Disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com