Power Maintenance Ladder

A technology for power maintenance and support legs, applied in ladders, electrical components, switchgear and other directions, can solve the problems of low maintenance operation efficiency, easy to cause electric shock, lack of real-time supervision and review by maintenance personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

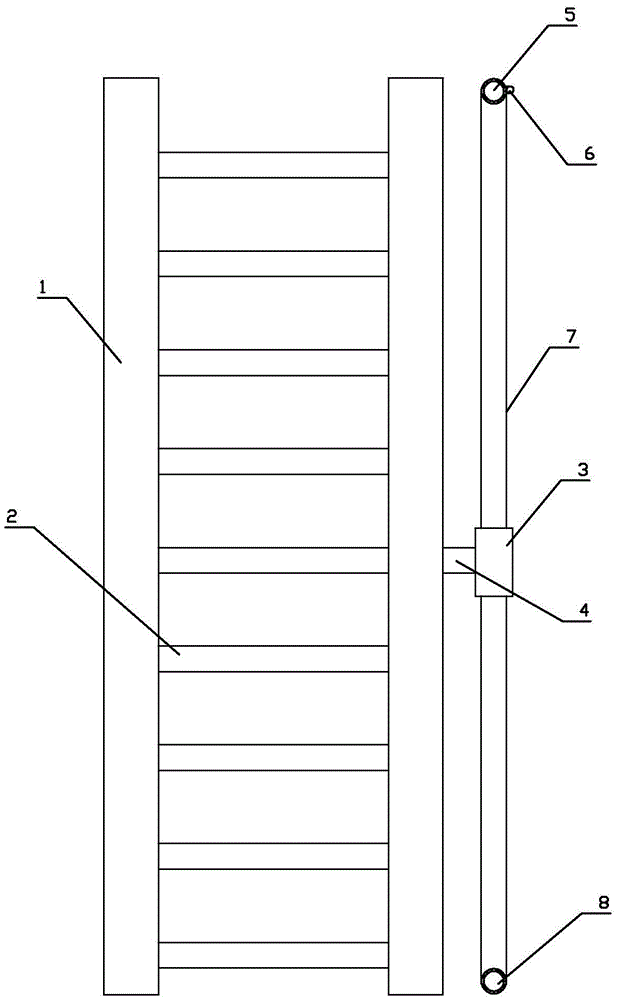

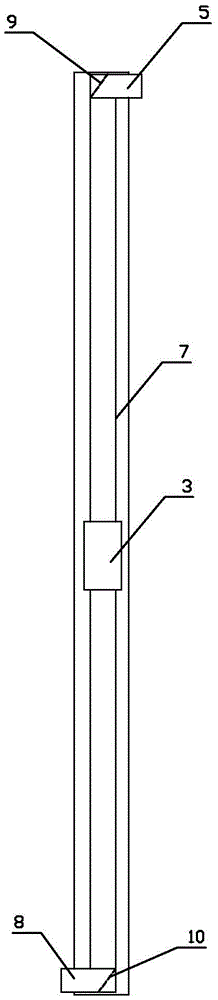

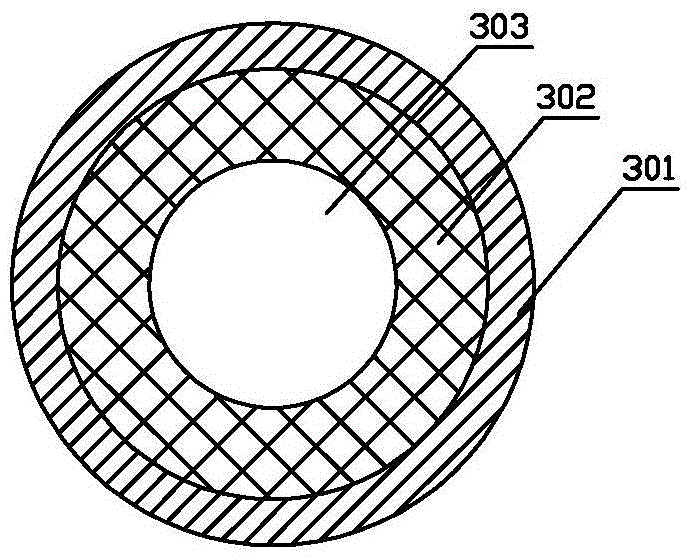

[0020] combined with Figures 1 to 5 , an electric maintenance ladder, which includes two support legs 1 and several beams 2 arranged between the support legs 1; it is characterized in that: it also includes a first observation device 7, a first bushing 3 and a connecting rod 4; The first observation device 7 includes an upper observation port 5 and a lower observation port 8, and the upper and lower observation ports are connected by a light guide; the upper observation port 5 is provided with an upper mirror body 9, and the lower observation port 8 is provided with a lower mirror body 10 , the upper mirror body 9 is used to reflect the scene in front of the upper observation port 5 to the lower mirror body 10; the first observation device 7 is plugged into the first sleeve 3, and the first sleeve 3 is connected to the support through the connecting rod 4 The legs 1 are connected; the first sleeve 3 includes a metal outer layer 301 and a rubber lining 302, the first sleeve 3 ...

specific Embodiment 2

[0022] On the basis of embodiment one, further combined with the attached Figure 6 , on the basis of the structure of the embodiment, the first sleeve 3 is changed to a clamp structure, that is, the metal outer layer 301 is an opening structure, and the opening extends out of the tightness adjustment port 304, and the elastic adjustment port 304 is connected to a useful The screw used to adjust the tightness of the clamp.

specific Embodiment 3

[0023] On the basis of embodiment two, further combined with the attached Figure 7 , the electric maintenance ladder also includes a second observation device 12 with the same structure as the first observation device 7, and the second observation device 12 is connected to the other support leg of the electric maintenance ladder through a second bushing 13 and a second connecting rod 1, that is, the other supporting leg 1 besides the first viewing device already installed.

[0024] In the above three embodiments, the light guide tube is a hollow tube, and its structure is the same as that of the tube connecting the two mirror bodies in the periscope, but since it is not used in water, it does not need to be sealed.

[0025] Except above above embodiment, the present invention can also make following improvements, 1, add a pair of handles 16 at the lower viewing port of each viewing device, so that the workers below can hold it better when rotating and lifting the viewing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com