380 V switch cabinet maintenance car

A technology for overhauling vehicles and switch cabinets, which is applied to switchgear, lifting devices, electrical components, etc. It can solve the problems of heavy weight of vehicle-type switches, difficulty in controlling the function, and laborious operation of operators, so as to achieve uniform force distribution and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

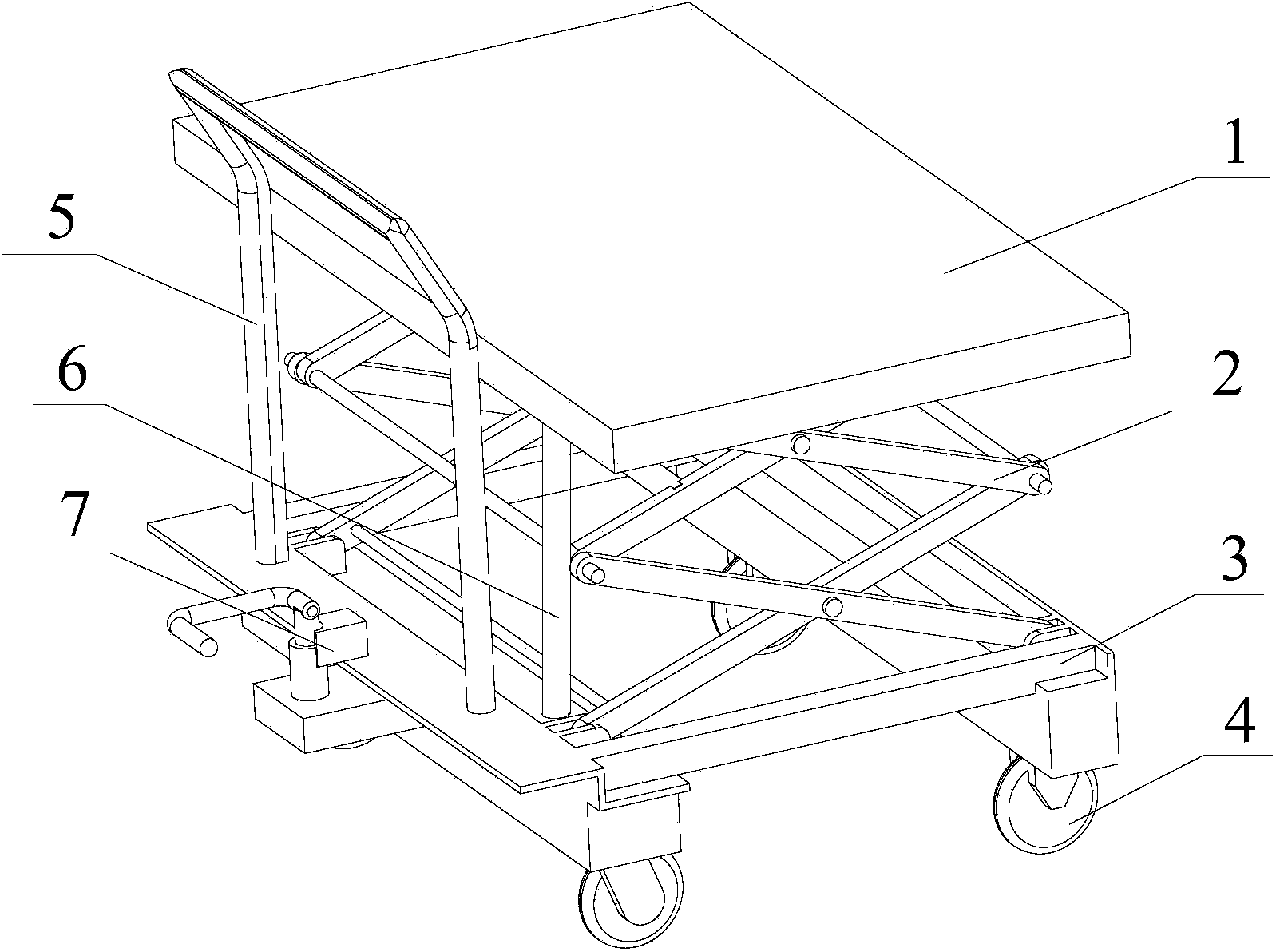

[0018] A 380V switch cabinet maintenance vehicle, its structure is as follows figure 1 As shown, it includes a car body 3, a universal wheel 4 connected to the bottom of the car body 3, a handle 2 connected to the side of the car body 1, a hydraulic support module arranged on the car body 1, and an inspection and maintenance unit connected to the top of the hydraulic support module. The platform 1 realizes lifting under the control of the hydraulic support module. In addition, it also includes a height limiting device 6, which is movably connected between the vehicle body 3 and the maintenance platform 1, and controls the height of the maintenance platform by controlling the height of the hydraulic support module. The lower surface of the maintenance platform 1 is provided with slide rails for sliding the maintenance platform 1 back and forth in the horizontal direction.

[0019] The height limiting device 6 adopted is a stretchable elastic connector, which can be a spring, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com