Direct-writing vacuum evaporating system and method thereof

A vacuum evaporation and direct writing technology, applied in vacuum evaporation plating, ion implantation plating, metal material coating technology, etc., can solve problems such as damage, pollution, and single coating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

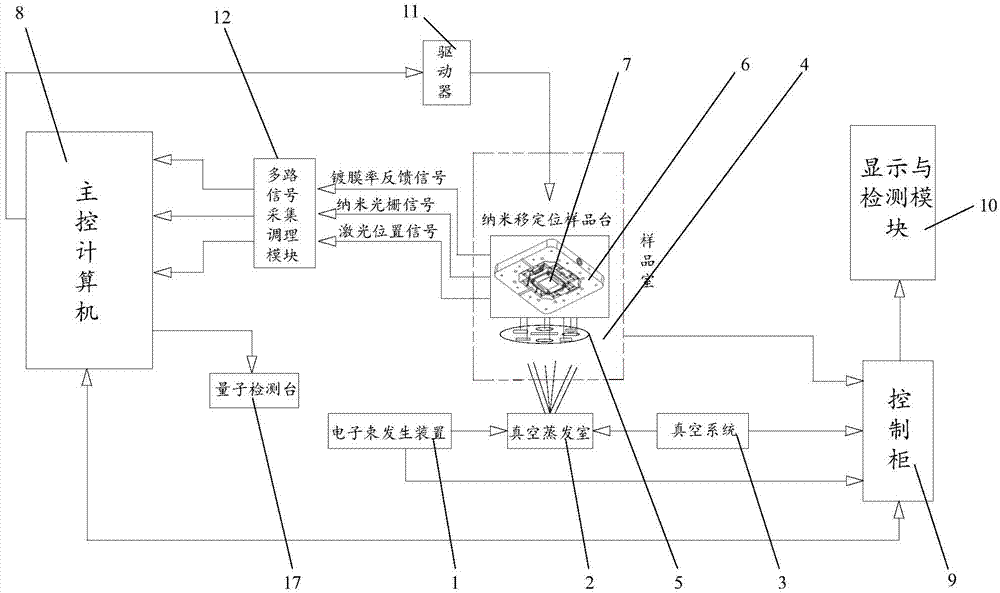

[0071] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0072] The present invention aims to break through the limitations of the existing coating method of vacuum evaporation technology, and to provide a direct writing method with nano-shift positioning sample processing table as the core technology for various processes and precision requirements in the preparation of quantum functional devices and materials. type vacuum evaporation system.

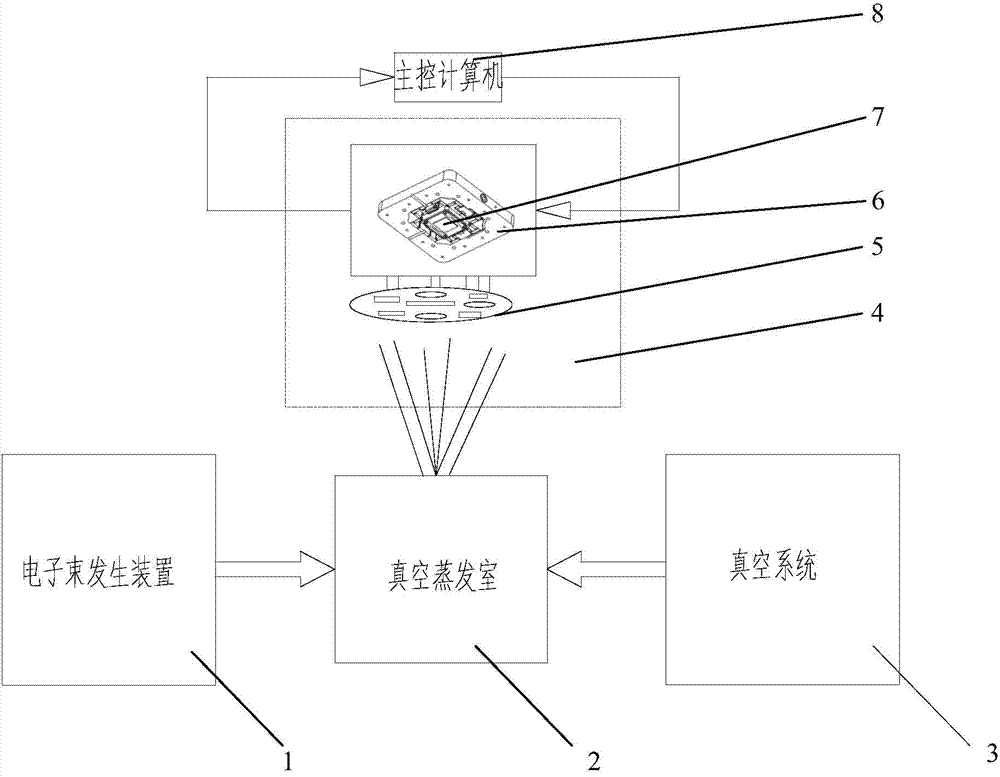

[0073] The direct-writing vacuum evaporation system of the present invention takes an ultra-precise robust tracking algorithm as the control core, and introduces a mask mechanism 5, a nano-shift positioning sample stage 6, and a main control computer on the basis of the existing electron beam vacuum evaporation system 8's trajectory generation module 13, positioning control module 15, tracking control module 14, and display and detection module 10 modules, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com