Electrode foil cutting device and method

A technology of cutting device and cutting method, which is applied in the direction of electrode manufacturing, battery electrodes, electrode carriers/collectors, etc., can solve the problems of speed change, poor quality, and difficult realization of mechanical devices, and achieve stable operation, excellent processing quality, and improved The effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

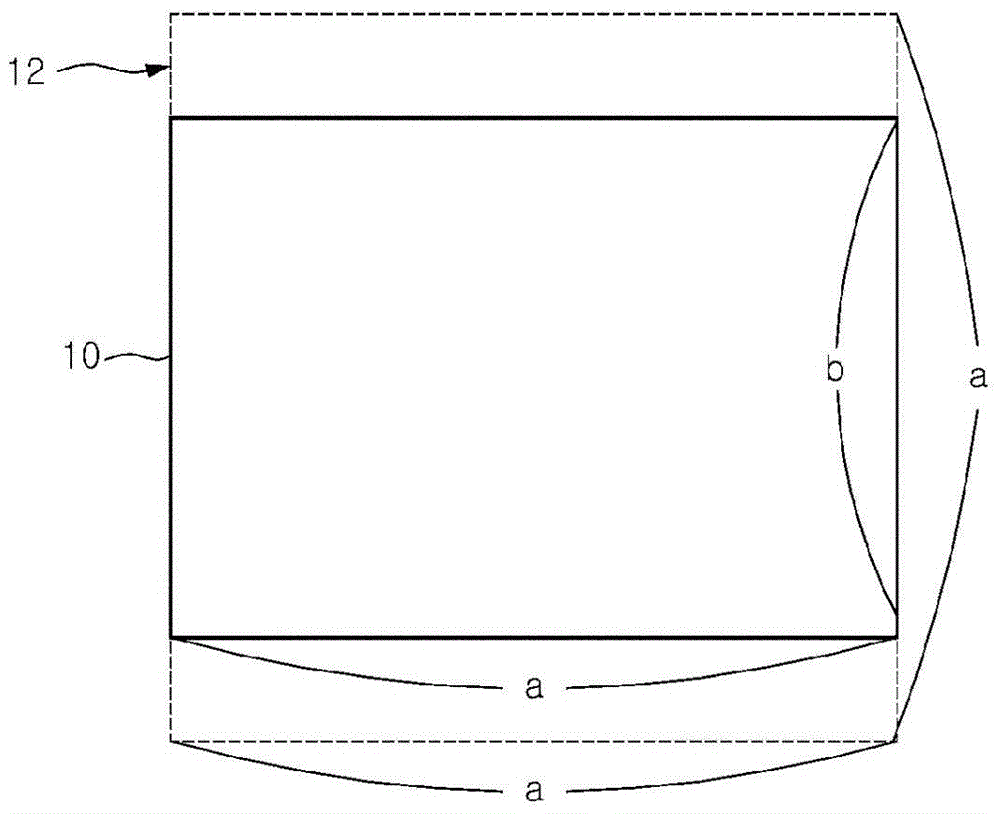

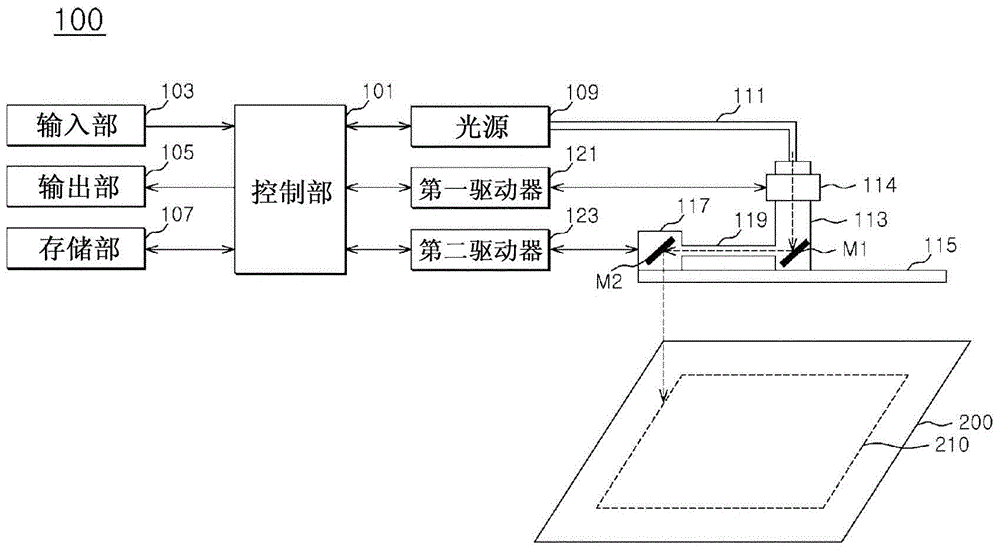

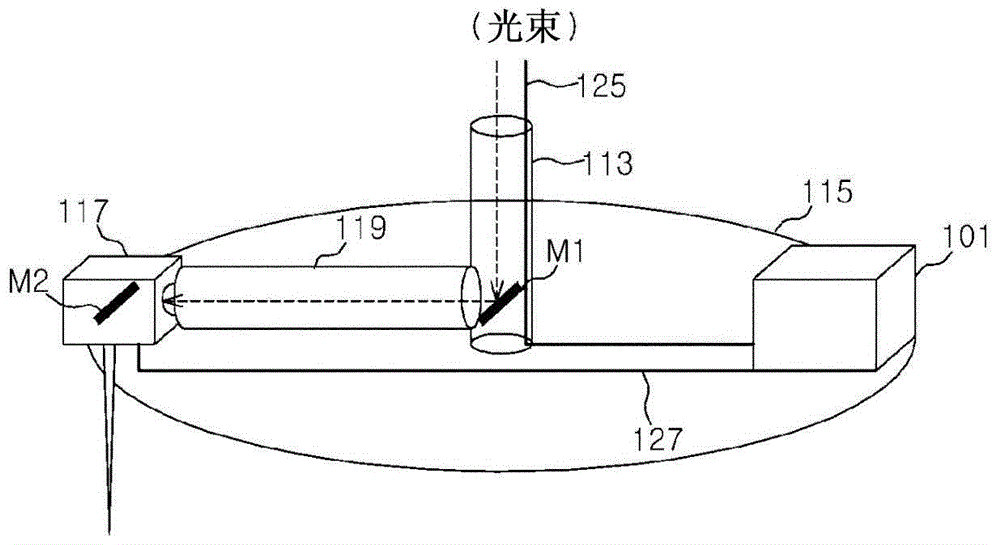

[0027] An electrode foil cutting device according to an embodiment of the present invention may include: a rotating body arranged horizontally and vertically at a prescribed distance from the workbench; a rotating shaft arranged at the center of the rotating body and driven by a first driver so that The rotating body rotates at a predetermined moving speed; and the scanner is installed at one end of the rotating body, and moves to the above-mentioned processing according to the rotation angle of the rotating body, the moving speed, and the speed change rate based on the processing size of the object to be processed. The above-mentioned processed portion of the object is irradiated with a laser beam.

[0028] Hereinafter, embodiments of the present invention will be described more specifically with reference to the drawings.

[0029] figure 2 It is a structural diagram of an electrode foil cutting device according to an embodiment of the present invention.

[0030] refer to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap