Device and method for increasing material separation rate through negative-pressure air system

A technology of air system and separation rate, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve the problems of increased loss, low one-time pass rate of shredded tobacco, and increased vibration sieve amplitude and frequency and other issues, to achieve the effect of improving production capacity and finished product quality, improving the first-pass rate, and reducing the number of vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

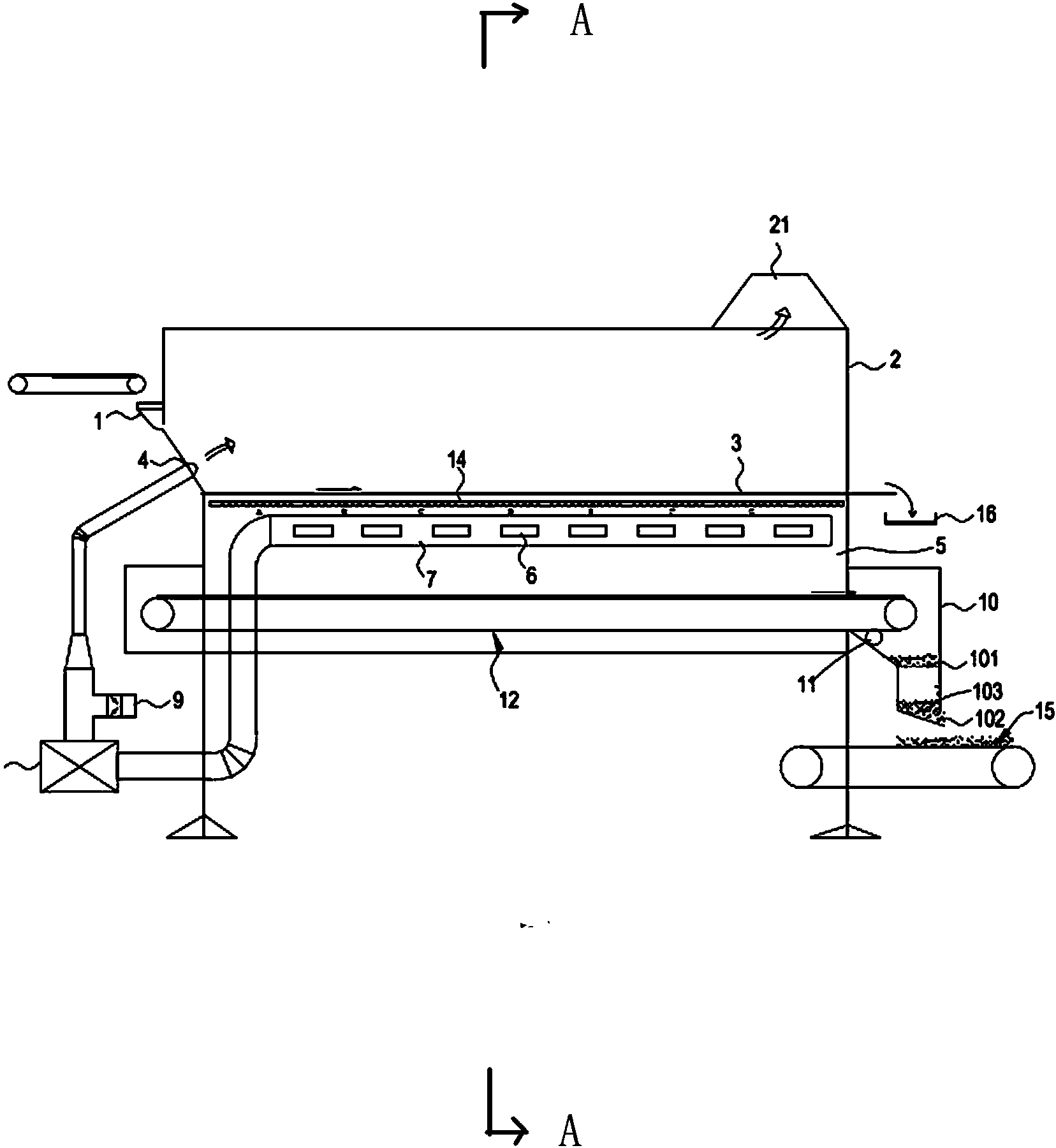

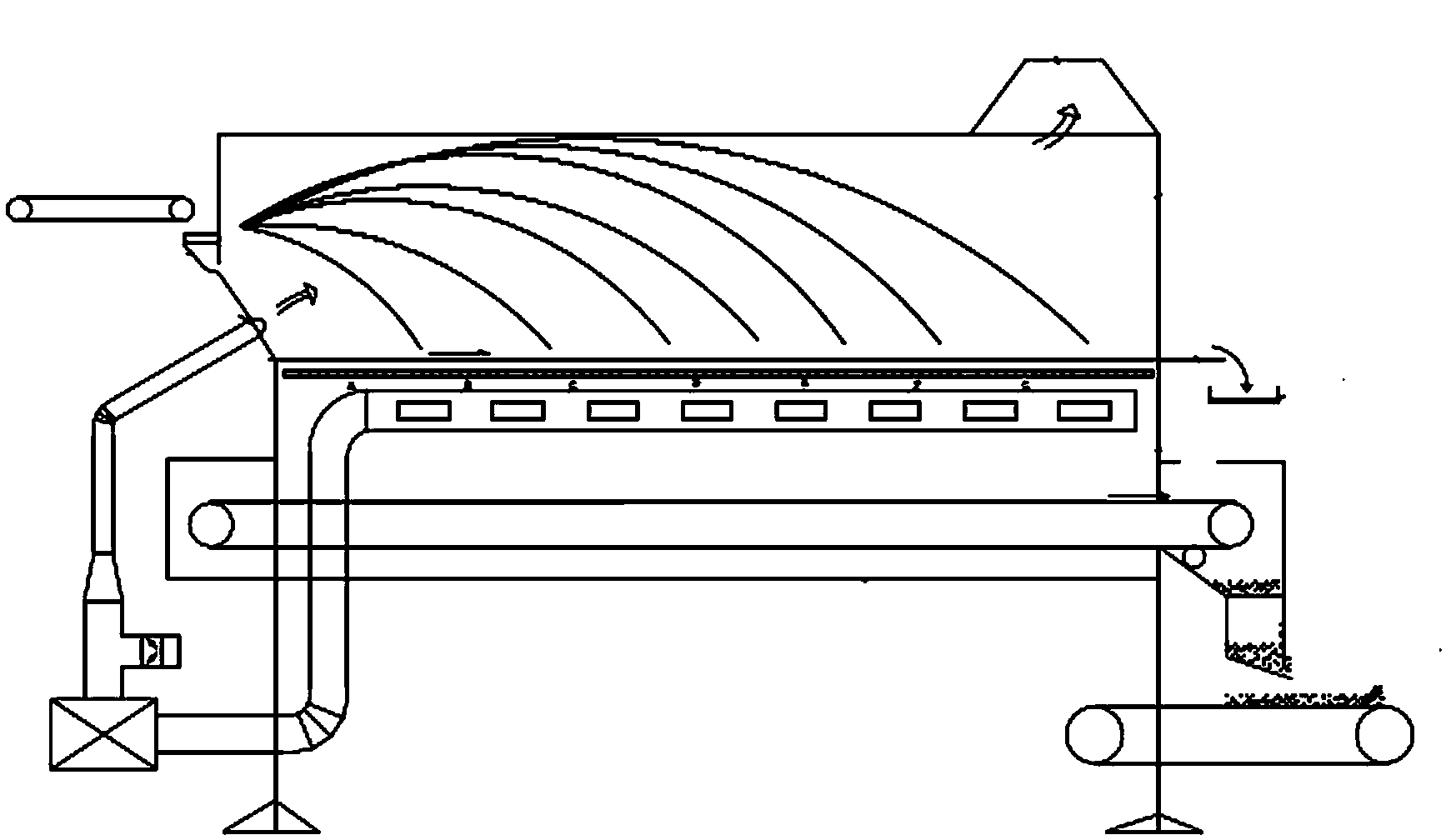

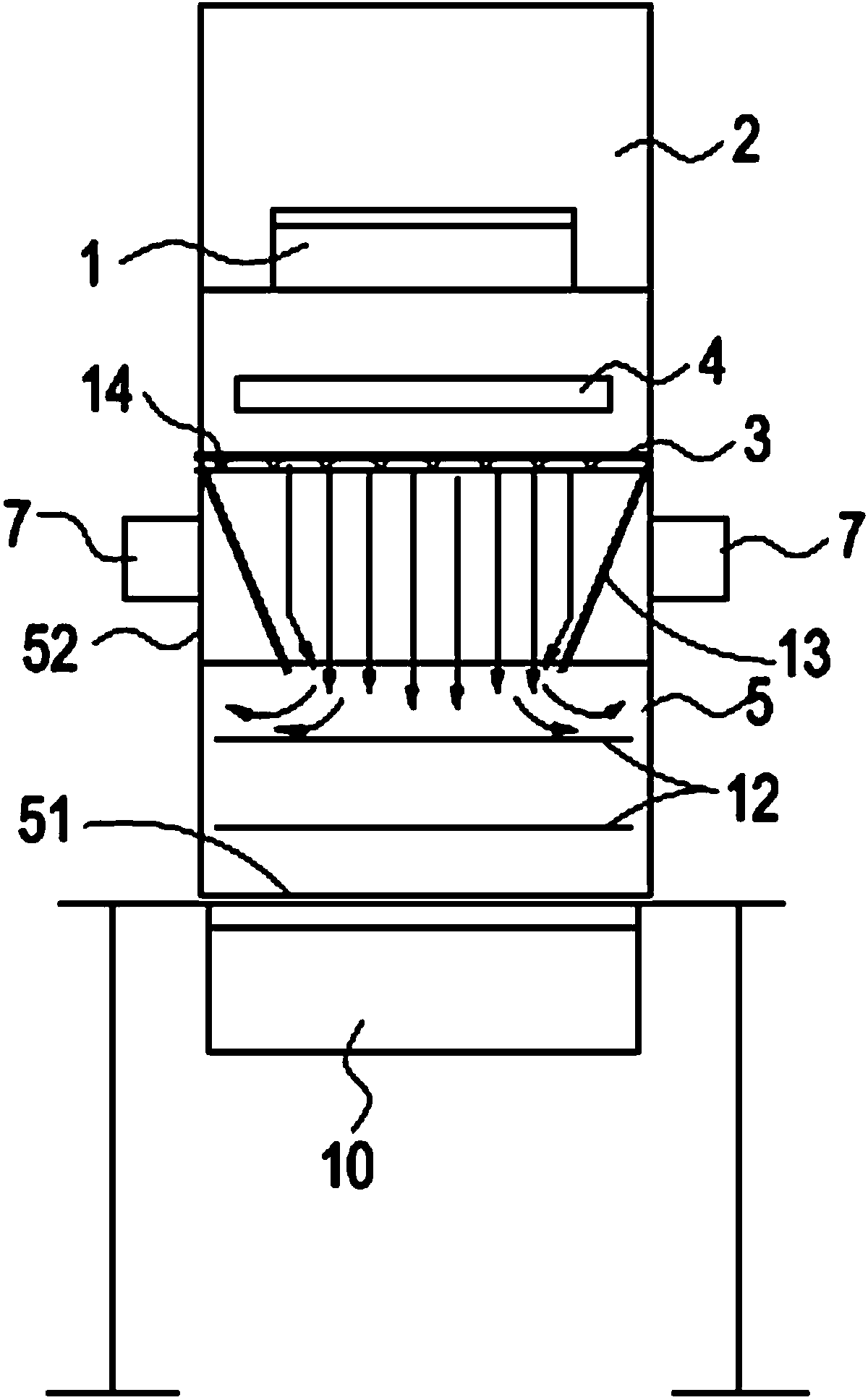

[0018] The present invention utilizes the negative pressure air system to improve the material separation rate equipment and method comprising a throwing bin with a material inlet, a vibrating screen arranged under the throwing bin, a material conveying device located under the vibrating screen, The negative pressure air system is arranged between the vibrating screen and the conveying device, the negative pressure air system includes a negative pressure air chamber, and the negative pressure chamber includes a first negative pressure area with a first negative pressure and A second negative pressure zone with a second negative pressure, the first negative pressure zone is connected to the vibrating screen, the second negative pressure zone is connected to the first negative pressure zone, and the The conveying device is located in the second negative pressure zone. Due to the above design, materials with low wind speed pass through the vibrating screen and fall directly onto t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com