Warehouse management auxiliary robot

A warehouse management and robot technology, applied in the field of warehouse management assistant robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

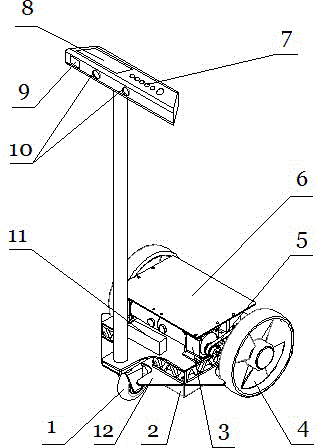

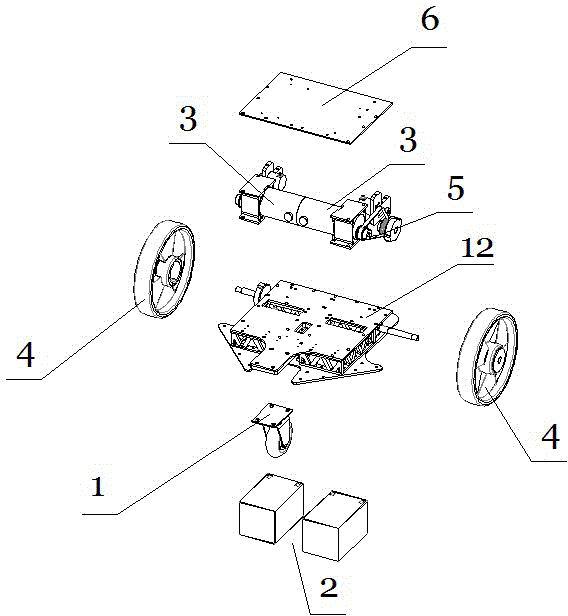

[0017] See attached figure 1 and figure 2 , the warehouse management assistant robot, including a follow-up universal wheel (1), two sets of animal battery packs (2), two DC motors (3), two driving rear wheels (4), two sets of synchronous transmission belts (5 ), stage (6), console (7), liquid crystal display (8), code reader (9), two image recognition cameras (10), integrated controller (11) and support frame (12). It is characterized in that: the follow-up universal wheel (1) is fixed and installed under the front end of the support frame (12) by bolts; two sets of animal battery packs (2) are embedded and fixed at the lower end of the support frame (12) from the bottom; two DC motors ( 3) They are respectively fixed on the upper end of the support frame (12) by bolts; the two driving rear wheels (4) are fixedly installed on the shafts on both sides of the support frame (12) through key connections; two sets of synchronous transmission belts (5) are respectively connected...

Embodiment 2

[0019] This embodiment is basically the same as Embodiment 1, and the special features are as follows: the main material of the support frame (12) is high-strength aluminum alloy; the follower universal wheel (1) and the two driving rear wheels (4) are Customized according to requirements; two DC motors (3) and two sets of synchronous transmission belts (5) are models selected according to different storage requirements; code reader (9) is a two-dimensional code reader; two image recognition cameras (10 ) are the grayscale and depth cameras, respectively.

[0020]

[0021] Instructions:

[0022] Start the robot through the control buttons on the console (7);

[0023] If you want to move the goods to the designated shelf, place the goods on the loading platform (6), and the robot will follow the warehouse manager to move to the designated shelf;

[0024] Before the goods are put on the shelf, read the QR code on the goods through the code reader (9), and record the relevant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com