Back loading type garbage compression vehicle

A technology of garbage compression and post-loading, which is applied in the direction of garbage receptacle, transportation and packaging, etc. It can solve the problems of spilling and the filling device can't complete the loading work independently, and achieve the effect of reliable operation, compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

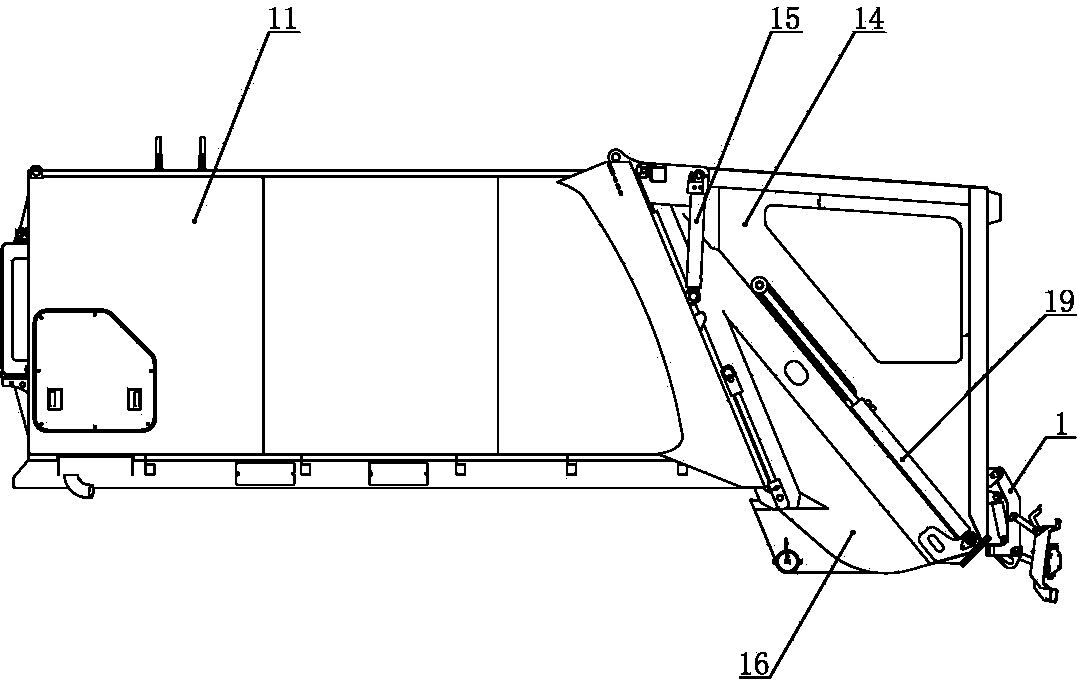

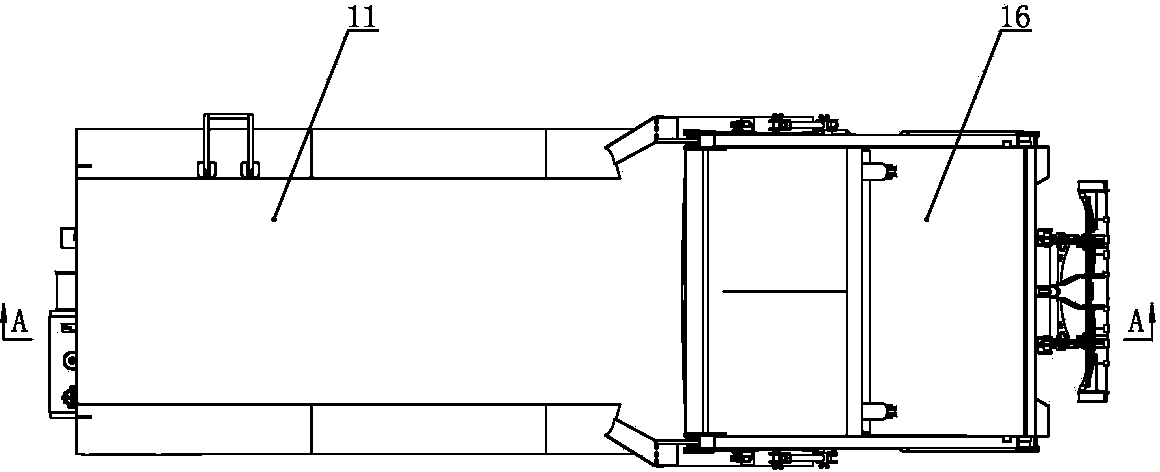

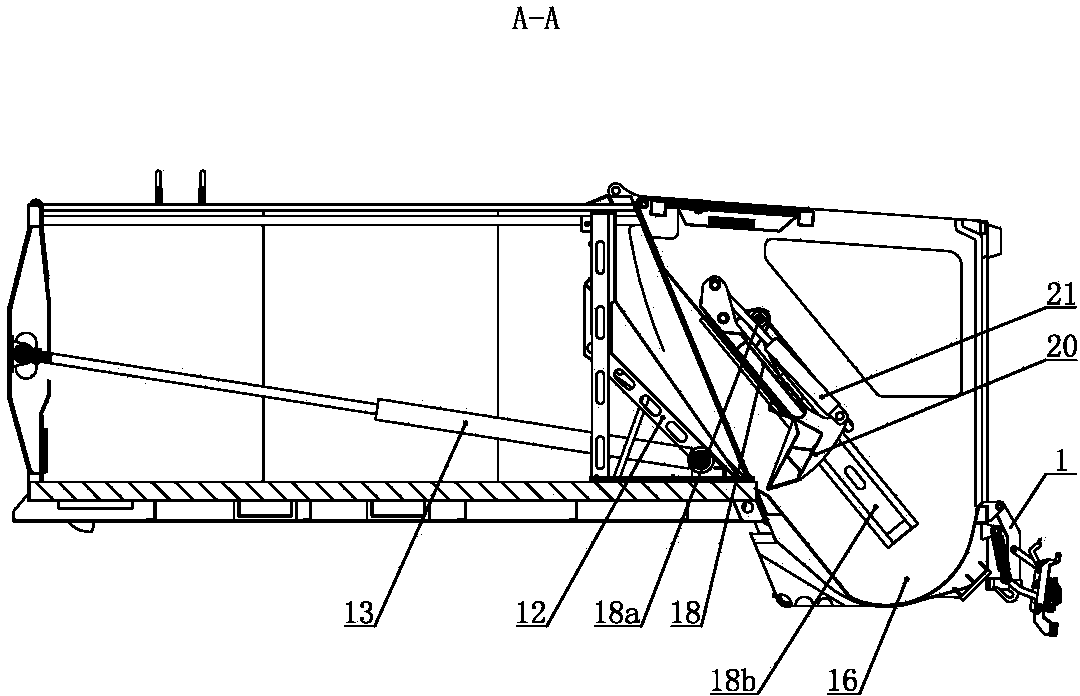

[0030] Such as Figure 1 to Figure 10 As shown, a compression box 11 is installed on the chassis of the rear-mounted garbage compression vehicle of the present invention, and the inner cavity of the compression box 11 is equipped with a push plate 12 that can move along the axis of the compression box, and the outer profile of the push plate 12 is consistent with the compression box. The inner peripheral wall of 11 is suitable, and the top of push plate 12 is vertical state, and the bottom is inclined backward, forms shovel shape, when being beneficial to garbage unloading, the rubbish at the bottom of the compression box is shoveled. The front end of push pedal 12 is hinged with push pedal oil cylinder 13, and the other end of push pedal oil cylinder 13 is hinged on the front wall of compression box 11.

[0031]The rear port of the compression box 11 is docked with the front part of the lifting bracket 14, the upper part of the rear port of the compression box 11 is inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com