Crane hook 90° positioning anti-rotation device

A crane and hook technology, applied in the field of lifting equipment, can solve the problems of high use cost, inconvenient operation, economic loss, etc., and achieve the effects of reducing outsourcing cost, compact structure and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the above-mentioned purpose, technical scheme and effect of the present invention, the present invention will be described below in conjunction with the accompanying drawings and relevant known technical knowledge through the embodiments:

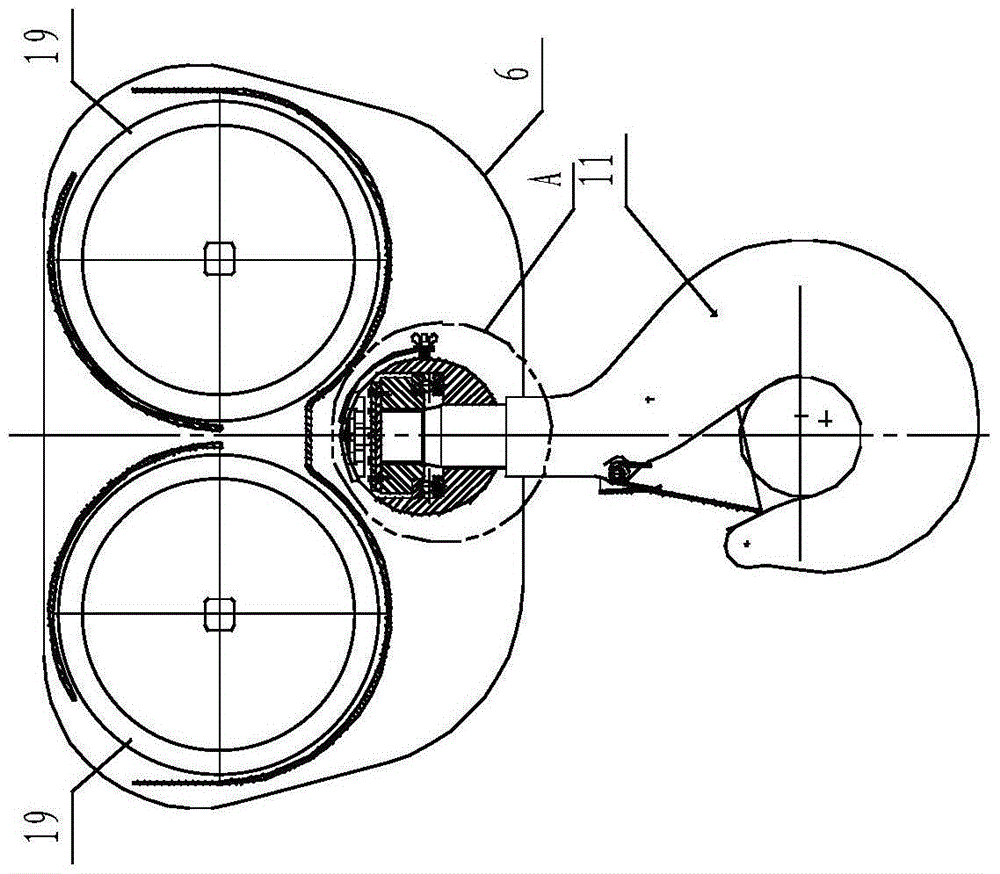

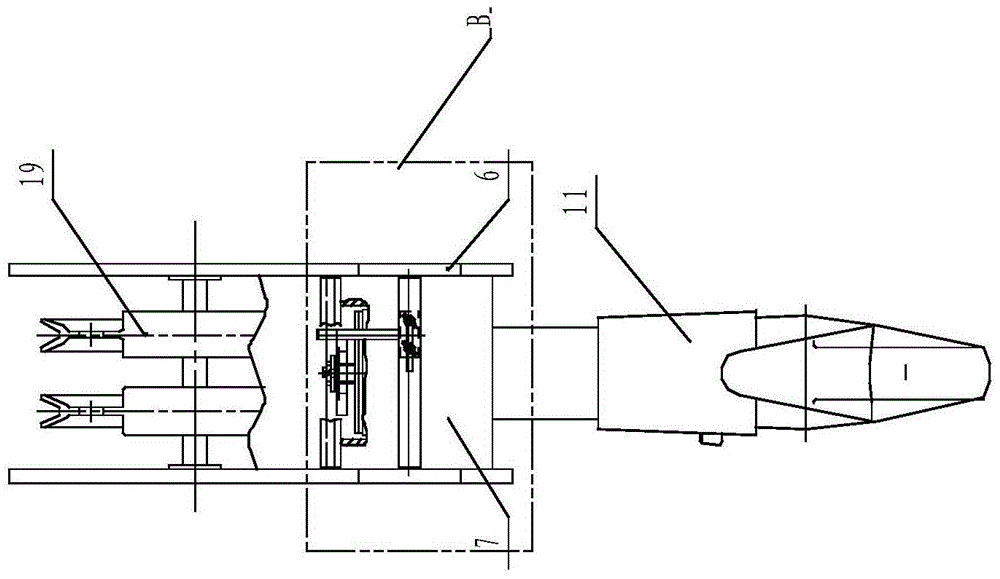

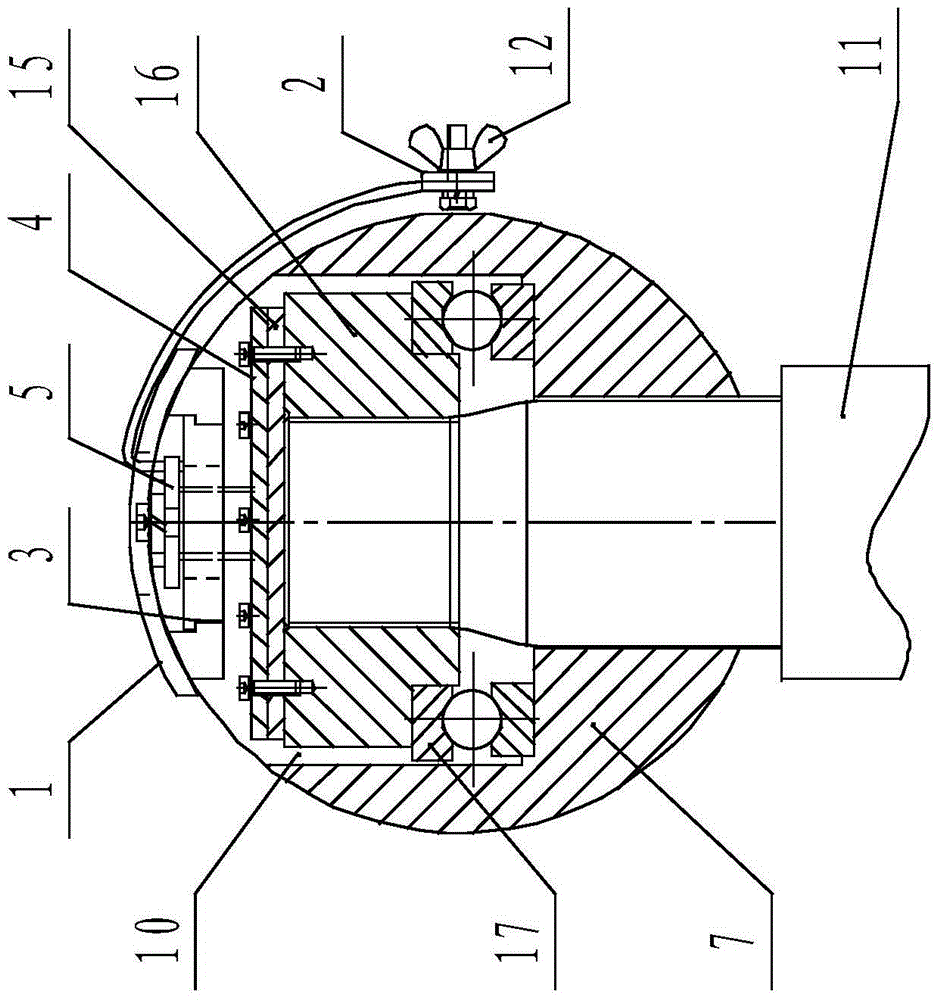

[0025] Such as Figure 1-3 As shown, the crane hook 90° positioning anti-rotation device includes a pulley block 19, two parallel hoisting yoke plates 6 and a hook block, and the pulley block 19 and the hook block located at the lower side of the pulley block 19 are arranged on two blocks. Between the hoisting yoke plates 6 arranged in parallel, the pulley block 19 is supported on the upper part of the two hoisting yoke plates 6 through a transverse shaft; The end lock plate 15, the upper end of the hook body 11 vertically penetrates into the hole set in the middle of the crossbeam 7, and after matching with the center hole of the thrust ball bearing 17, the screw at the upper end of the hook body 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com