Automatic grapple

An automatic and beam lifting technology, applied in the field of grapple hooks, can solve the problems of many intermediate transmission links, inflexible action of the grapple hook, affecting the lifting of the gate, etc., and achieves the effect of reducing transmission links, simple and reasonable structure, and safe and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

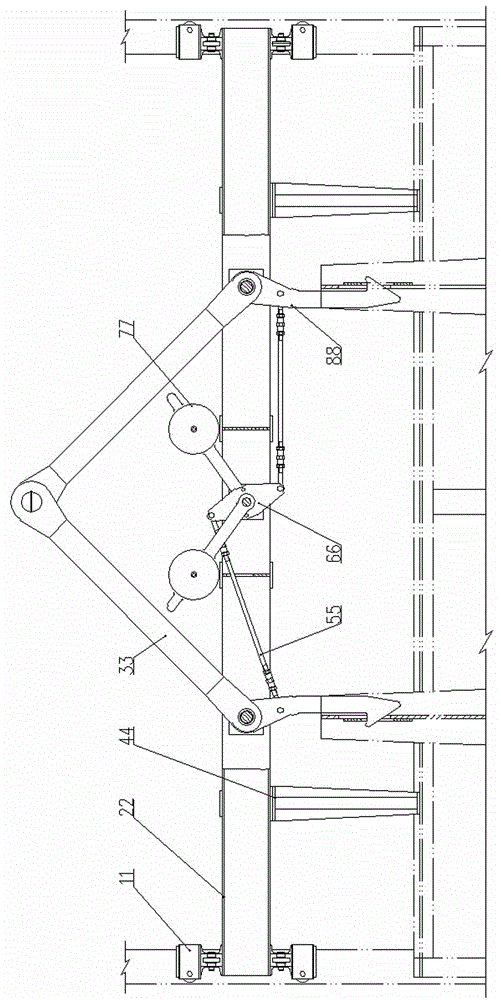

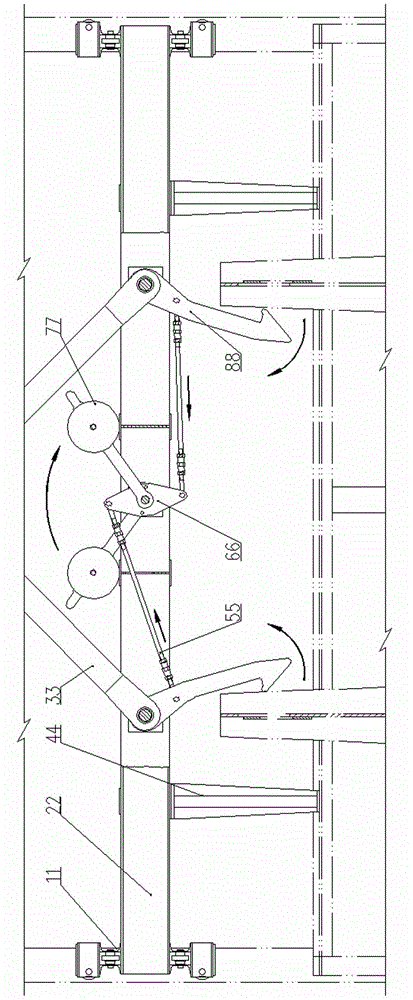

[0021] In the description of the drawings, the number 11 guide mechanism, 22 suspension beam, 33 tie rod, 44 limit device, 55 linkage mechanism, 66 steering mechanism, 77 working hammer, 88 hook;

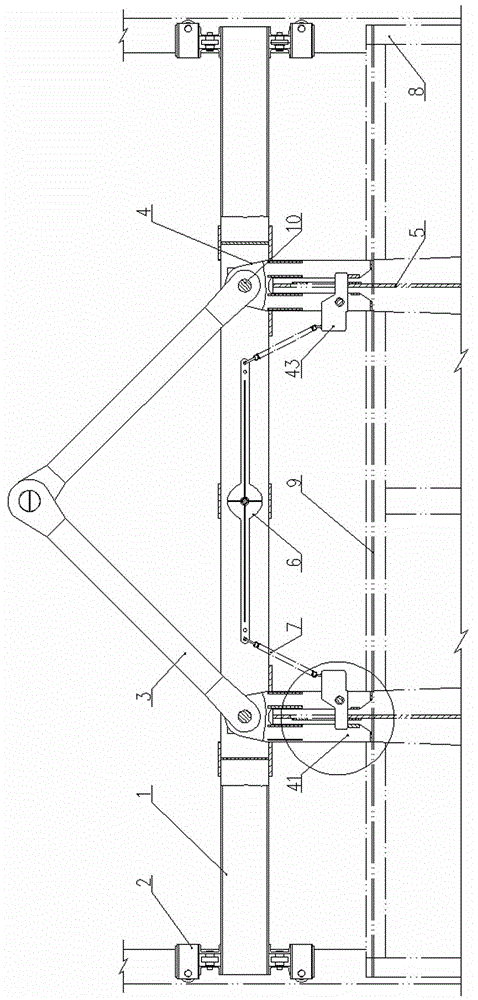

[0022] Labels 1 hanging beam, 2 guiding mechanism, 3 pull rod, 4 grasping and releasing mechanism, 41 door frame, 42 through slot, 43 claw, 44 hanging ring, 45 stopper, 46 flat foot, 5 gate lifting lug, 6 linkage mechanism, 7 extension springs, 8 gate grooves, 9 gates, 10 bearing pins.

[0023] The automatic grab hook of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0024] Refer to attached figure 1 , attached figure 2 , the traditional automatic grab hook mainly includes guide mechanism 11, hanging beam 22, pull rod 33, limit device 44, connecting rod mechanism 55, steering structure 66, working hammer 77, hook 88, and it relies on the gravity effect of working hammer 77, The hook 88 is driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com