Artificial preparation method of fragile material

A technique of artificial preparation of fragile materials, applied in the field of artificial preparation of fragile materials, to achieve the effects of good singleness, good uniformity, and simple sample preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, further illustrate the present invention.

[0021] A method for artificially preparing fragile materials, characterized in that it comprises the following steps:

[0022] Step 1, preparation of raw materials:

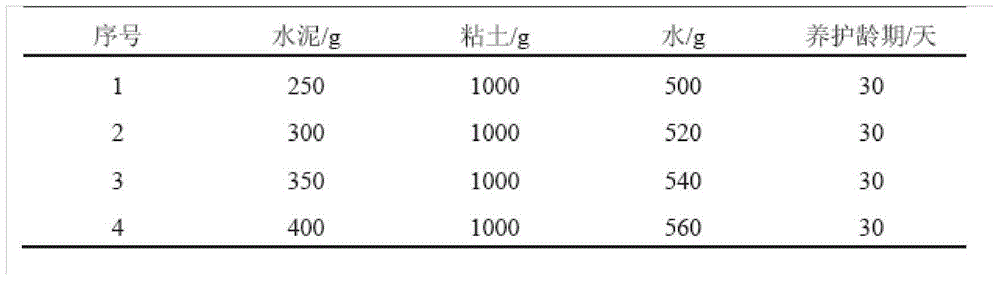

[0023] The raw materials used are cement, clay, and water, and the mass ratio of the cement, clay, and water is 250-400:1000:50-560;

[0024] Step 2, stir:

[0025] Put the raw materials in step 1 in a container, and stir evenly to obtain cement slurry, the plastic viscosity of which is 0.009 Pa·s.

[0026] Step three, granulation:

[0027] The cement slurry that step 2 is obtained is kneaded into the particle that diameter is 20mm;

[0028] Step four, pressing:

[0029] The granules prepared in step 3 are put into a mold with a circular groove, and pressed to obtain spherical granules with a size of 20mm;

[0030] Step five, shaping:

[0031] The spherical granules prepared in step 4 were shaped for 24 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com