A kind of preparation method of high-purity high-quality hexamethyldisiloxane

A technology of hexamethyldisiloxane and trimethylmonochlorosilane, which is applied in the field of preparation of high-purity and high-quality hexamethyldisiloxane, and can solve problems such as equipment corrosion, excessive chloride ion content, and increased production costs , to achieve the effect of shortening the reaction time, reducing water content and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Add 400g of pure water to a 2L four-neck flask, then add 20g of zeolite, and drop 1085g of trimethylchlorosilane (product of Zhejiang Zhongtian Fluorosilicon Materials Co., Ltd., purity 99.5%) into the flask to control the reaction The temperature is 60°C, the stirring speed is 400r / min, reflux, and react for 2h;

[0017] (2) Let it stand for 10 minutes, and separate the middle and lower layers. Add 800g of pure water to the upper oil phase, wash with high-speed stirring at 30°C for 0.5h, separate the upper oil phase, and continue to add 2% NaHCO 3 The solution is neutralized to neutral, the upper oil phase is separated, and the washing process is repeated twice;

[0018] (3) Add 100g of anhydrous calcium chloride to the obtained oil phase, stir for 0.5h, and filter;

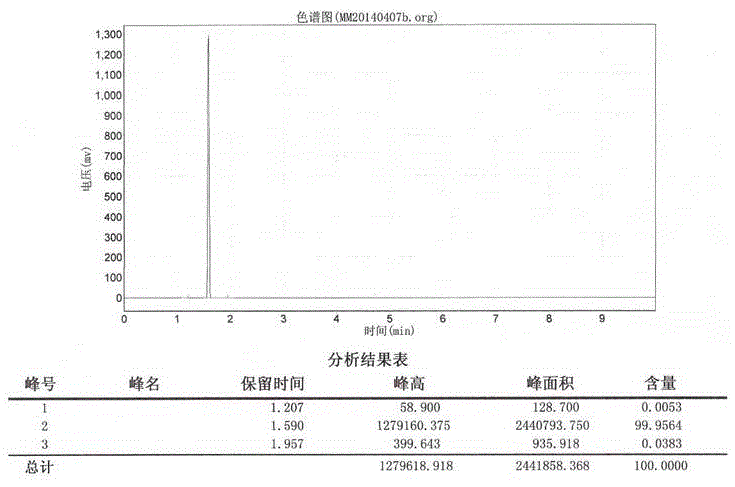

[0019] (4) Fractional distillation, collecting the fraction at 99-102°C, the chromatographic analysis results showed that the content of hexamethyldisiloxane was 99.95%.

Embodiment 2

[0021] (1) Add 200g of pure water to a 2L four-necked flask, then add 20g of cation exchange resin, and drop 1085g of trimethylsilyl chloride (product of Zhejiang Zhongtian Fluorosilicon Materials Co., Ltd., purity 99.5%) into the flask, Control the reaction temperature at 70°C, stir at 600r / min, reflux, and react for 2h;

[0022] (2) Let it stand for 10 minutes, and separate the middle and lower layers. Add 800g of pure water to the upper oil phase, wash with high-speed stirring and water at 40°C for 0.5h, separate the upper oil phase, and continue to add 2%Na 2 CO 3 The solution is neutralized to neutral, the upper oil phase is separated, and the washing process is repeated twice;

[0023] (3) Add 150g of anhydrous magnesium chloride to the obtained oil phase, stir for 0.5h, and filter;

[0024] (4) Fractional distillation, collecting the fraction at 99-102°C, the chromatographic analysis results showed that the content of hexamethyldisiloxane was 99.96%.

Embodiment 3

[0026] (1) Add 90g of pure water to a 2L four-necked flask, then add 20g of cation exchange resin, and drop 1085g of trimethylsilane monochlorosilane (product of Zhejiang Zhongtian Fluorosilicon Materials Co., Ltd., purity 99.5%) into the flask, Control the reaction temperature at 80°C, stir at 800r / min, reflux, and react for 2h;

[0027] (2) Let it stand for 10 minutes, and separate the middle and lower layers. Add 800g of pure water to the upper oil phase, wash with high-speed stirring at 50°C for 0.5h, separate the upper oil phase, and continue to add 2% K 2 CO 3 The solution is neutralized to neutral, the upper oil phase is separated, and the washing process is repeated twice;

[0028] (3) Add 150g of anhydrous magnesium sulfate to the obtained oil phase, stir for 1 hour, and filter;

[0029] (4) Fractional distillation, collecting the fraction at 99-102°C, the chromatographic analysis results showed that the content of hexamethyldisiloxane was 99.98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com