A method for preparing superhydrophobic silicon dioxide powder and superhydrophobic coating with composite silicon source

A technology of silica powder and super-hydrophobic coating, applied in the directions of silica, silicon oxide, coating, etc., can solve the problems of complex process, inability to expand the scope of application, high cost, and achieve the effect of strong super-hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

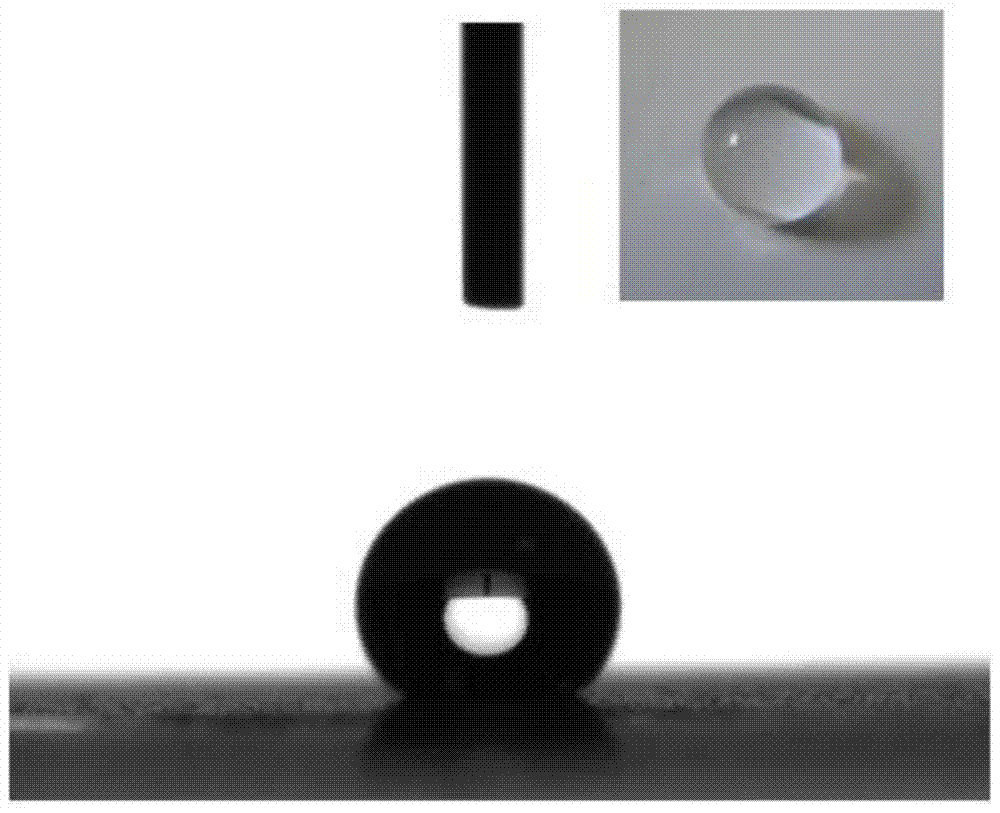

[0030] A preparation method of superhydrophobic silica powder and superhydrophobic coating based on glass, comprising the following steps

[0031] 1) Dissolve sodium silicate in water, and prepare a sodium silicate aqueous solution with a concentration of 0.1-0.5mol / L under the condition of sufficient stirring, and dissolve ethyl orthosilicate in a certain volume of absolute ethanol to make a concentration Alcoholic solution of 2-4mol / L tetraethyl orthosilicate;

[0032] 2) Under the action of magnetic stirring, slowly add tetraethyl orthosilicate alcohol solution into sodium silicate aqueous solution, the volume ratio of the two is 1:2, after a period of time, white suspensions begin to appear in the system;

[0033] 3) Use concentrated hydrochloric acid to adjust the pH value of the solution in the above system to 2-4, then continue the magnetic stirring reaction for 2-4 hours, filter the obtained white precipitate, wash with water and ethanol three times, dry at 100°C for 0...

Embodiment 1

[0039] 1) Sodium silicate is dissolved in water, and a sodium silicate aqueous solution with a concentration of 0.2mol / L is prepared under the condition of sufficient stirring;

[0040] 2) dissolving ethyl orthosilicate in a certain volume of absolute ethanol to configure a 2mol / L ethyl orthosilicate alcohol solution;

[0041] 3) Under the action of magnetic stirring, slowly add 50mL tetraethyl orthosilicate alcohol solution into 100mL sodium silicate aqueous solution, and a white suspension appears in the solution;

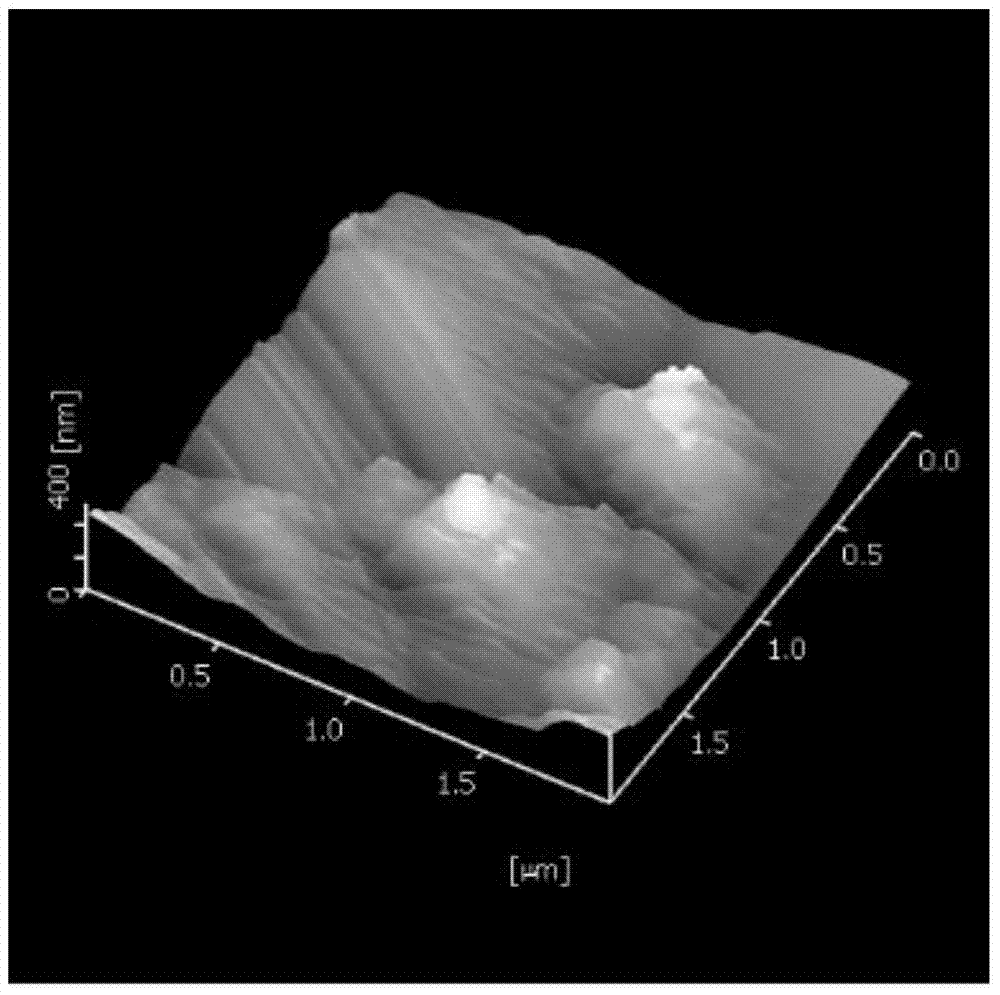

[0042] 4) Use hydrochloric acid to adjust the pH value of the solution in the above system to 2, then continue the magnetic stirring reaction for 2 hours, filter the obtained white precipitate, rinse with water and ethanol three times, dry it for 0.5 hours, and then calcinate it at 500°C for 2 hours to obtain micro- Nanostructured silica;

[0043] 5) Dissolve 1g of silicon dioxide and 8g of vinyltrimethoxysilane in 100mL of anhydrous ethyl alcohol and mix them e...

Embodiment 2

[0046] 1) Dissolving sodium silicate in water, and forming a sodium silicate aqueous solution with a concentration of 0.2mol / L under sufficient stirring conditions;

[0047] 2) dissolving ethyl orthosilicate in a certain volume of absolute ethanol to configure a 2mol / L ethyl orthosilicate alcohol solution;

[0048] 3) Under the action of magnetic stirring, slowly add 50mL tetraethyl orthosilicate alcohol solution into 100mL sodium silicate aqueous solution, and a white suspension appears in the solution;

[0049] 4) Use hydrochloric acid to adjust the pH value of the solution in the above system to 2, then continue the magnetic stirring reaction for 2 hours, filter the obtained white precipitate, wash it with water and ethanol three times, dry it for 0.5 hour, and then calcinate it at 500°C for 3 hours to obtain micro - nanostructured silica;

[0050] 5) Dissolve 1g of silicon dioxide and 10g of vinyltrimethoxysilane in 150mL of anhydrous ethyl alcohol and mix them evenly, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com