The preparation method of polyurethane capsule

A polyurethane and polyurethane acrylate technology, which is applied in the field of rapid preparation of polyurethane capsules, can solve the problems of long reaction time, low production efficiency, and limited effective solid content, and achieve high encapsulation efficiency, simple process, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Stir 100g n-hexadecane, 100g hexafunctional aliphatic urethane acrylate, 10g2,4,6-trimethylbenzoyl-diphenylphosphine oxide and 100g cyclohexane to obtain an oil phase solution; The oil phase solution was added into 500 g of PVA aqueous solution with a concentration of 5 wt%, and then emulsified at a high speed at 5000 rpm for 15 minutes to obtain a stable oil-in-water emulsion. Transfer the above-mentioned oil-in-water emulsion to a three-necked quartz flask, and irradiate the polyurethane capsule suspension with a power of 150w and a wavelength of 360nm for 15min while stirring at a speed of 100rpm to obtain the polyurethane capsule suspension. Filter, wash and dry to obtain polyurethane capsules.

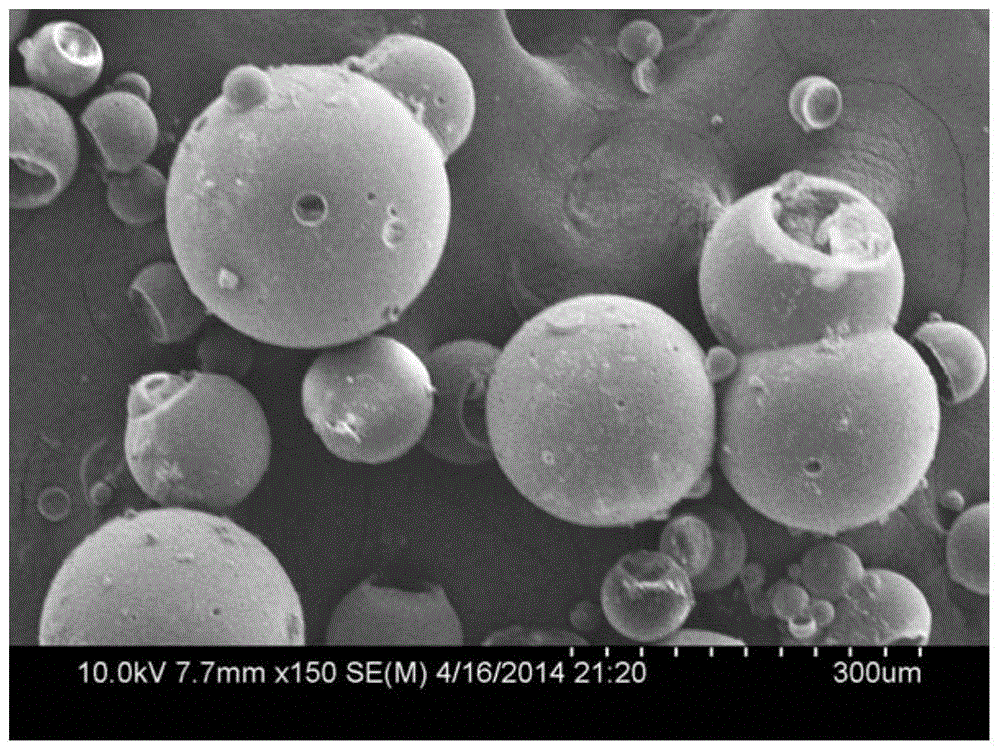

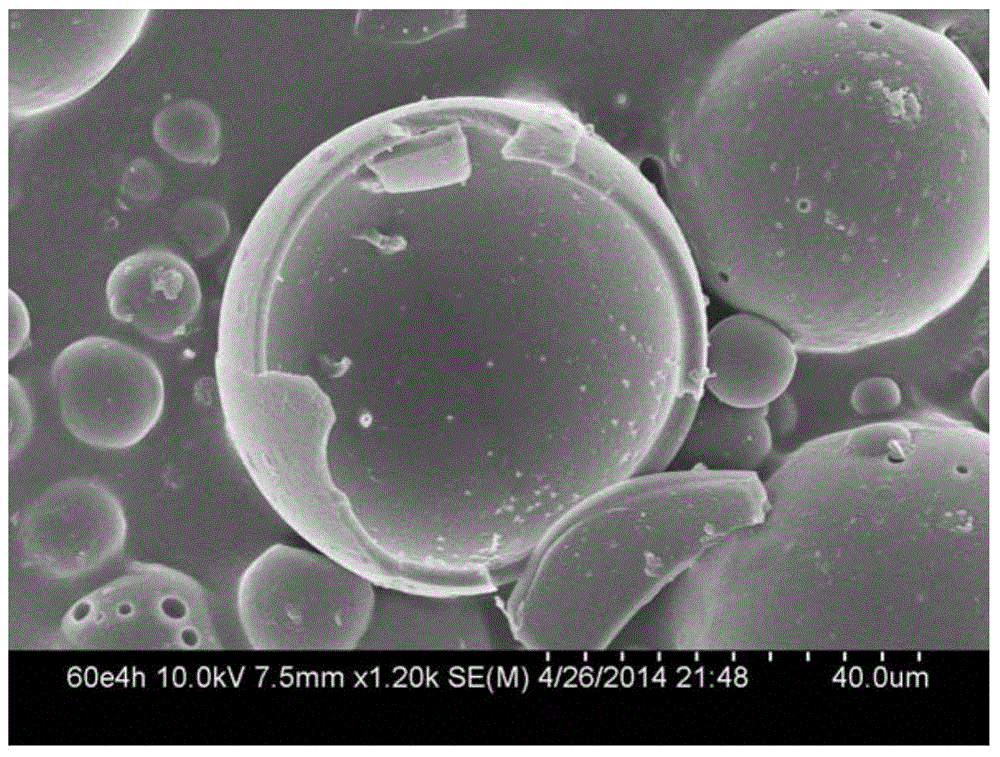

[0026] The appearance of the polyurethane capsule that present embodiment makes is as figure 1 , 2 shown, from figure 1 It can be seen that the surface of the polyurethane capsules prepared in this example is smooth and dense, in a regular spherical shape. exist figur...

Embodiment 2

[0031] In order to increase the flexibility of the capsule wall, a difunctional aliphatic urethane acrylate was selected as a comonomer. The aliphatic urethane acrylate of 1kg lauryl alcohol, 800g difunctionality, the aliphatic urethane acrylate of 200g hexafunctionality, 50gITX photoinitiator and 1000g acetone are stirred to obtain oil phase solution; This oil phase solution is added to by 100g sodium lauryl sulfate and 400g polyacrylic acid are dissolved in the emulsifier aqueous solution prepared by 5kg water, and emulsified at a high speed for 30 minutes at 8000rpm to obtain an oil-in-water emulsion with an average particle diameter of 1.6 μm; Transfer the oily emulsion to an open glass beaker, and irradiate it with ultraviolet light with a power of 1kw and a wavelength of 370nm while stirring at a speed of 200rpm. After reacting for 30min, a polyurethane capsule suspension can be obtained, and the polyurethane capsule suspension is filtered , washing and drying to obtain ...

Embodiment 3

[0034] Mix 20kg mosquito repellent incense oil, 15kg difunctional aromatic urethane acrylic acid, 5kg hexafunctional aliphatic urethane acrylate, 1kg benzophenone, 0.5kg BDK photoinitiator and 15kg acetone to obtain an oil phase solution; Add this oil phase solution to an emulsifier aqueous solution prepared by dissolving 10kg sodium polyacrylate in 100kg water, and emulsify at a high speed for 30 minutes at 2000rpm to obtain an oil-in-water emulsion with an average particle size of 10μm. Under the action of air pressure, the above-mentioned oil-in-water emulsion was drawn out with a silicone tube, and then returned to the reaction vessel, and the silicone tube with the oil-in-water emulsion flowing was irradiated with ultraviolet light with a power of 2kw and a wavelength of 230nm, and reacted for 1.5h The polyurethane capsule suspension of the mosquito repellent essence can be obtained, and the morphology and structure of the sample are observed with a scanning electron micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com