Exhaust gas detection and treatment, and related systems

a technology of exhaust gas and detection and treatment, applied in the direction of engines, mechanical equipment, machines/engines, etc., can solve the problems of less accurate sensors used, and achieve the effects of reducing particulate matter, reducing pollutants from the exhaust system, and improving accuracy of estimations and predicted chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

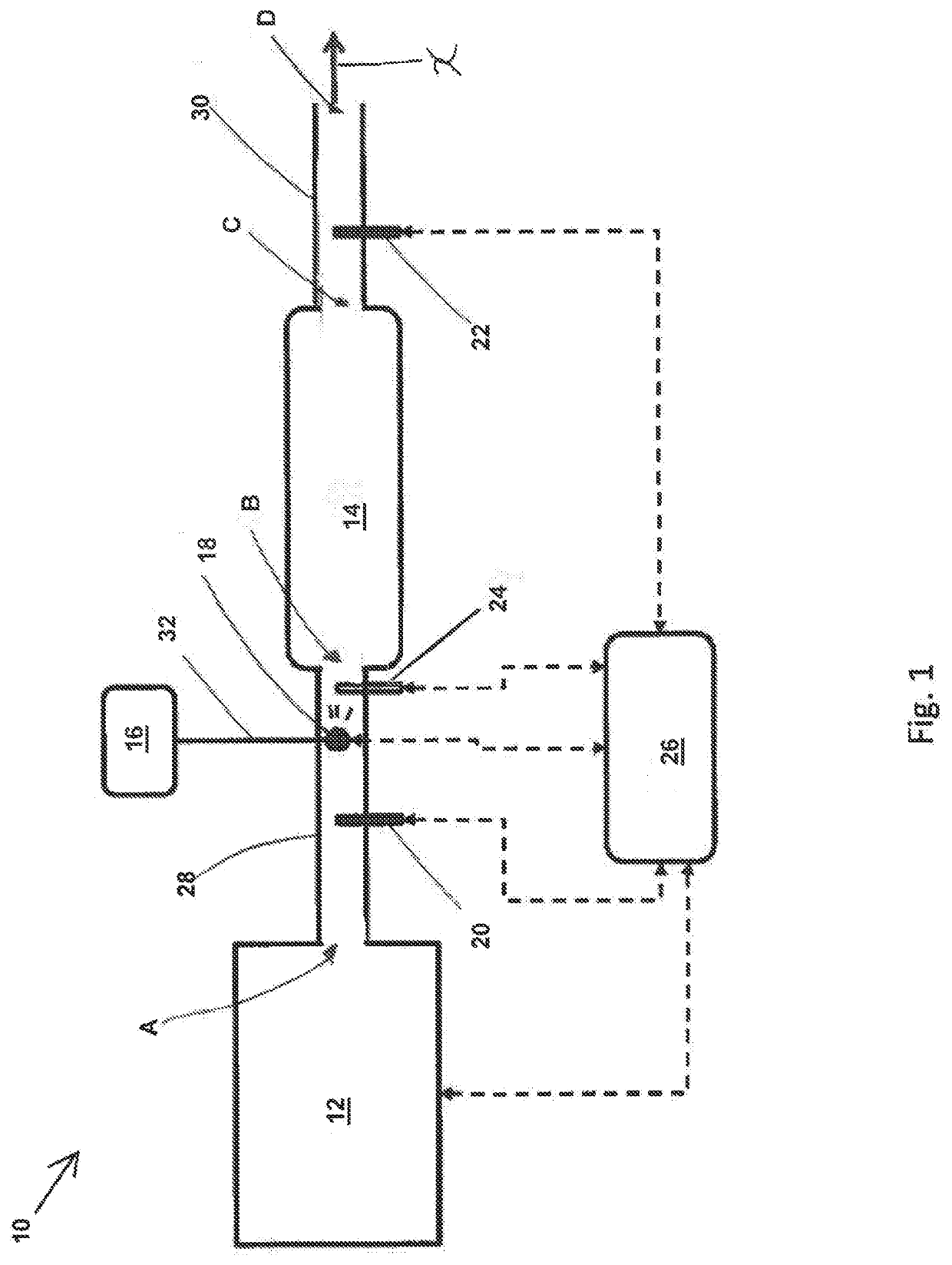

[0018]FIG. 1 is a simplified schematic of an exhaust system 10. The exhaust system 10 in this particular example is for an agriculture vehicle, such as a tractor, but may also be used for other exhaust gases (e.g., from engines in over-the-road vehicles, from stationary sources, etc.). The arrow X indicates the direction of flow of gases through the exhaust system 10, from upstream to downstream. It will be understood that throughout the following description, that another source of NH3 besides urea (e.g., anhydrous ammonia) may be used.

[0019]The exhaust system 10 includes an internal combustion engine 12, a catalytic converter 14, a urea tank 16, a urea injector 18, an upstream NOx sensor 20, a downstream NOx sensor 22, a temperature sensor 24, and an engine control unit 26.

[0020]The internal combustion engine 12 in this example is specifically a diesel engine. The internal combustion engine 12 is configured to drive a transmission of the tractor. In alternative embodiments, the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com