Nitrogen safety valve used by coalmine fully-mechanized mining hydraulic bracket

A technology of hydraulic support and nitrogen gas, which is applied in the direction of mine roof supports, pillars/supports, mining equipment, etc. It can solve the problems of unstable spring pressure, small pressure range of safety valves, and small pressure range of springs, etc., to achieve constant spring pressure , wide pressure range, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

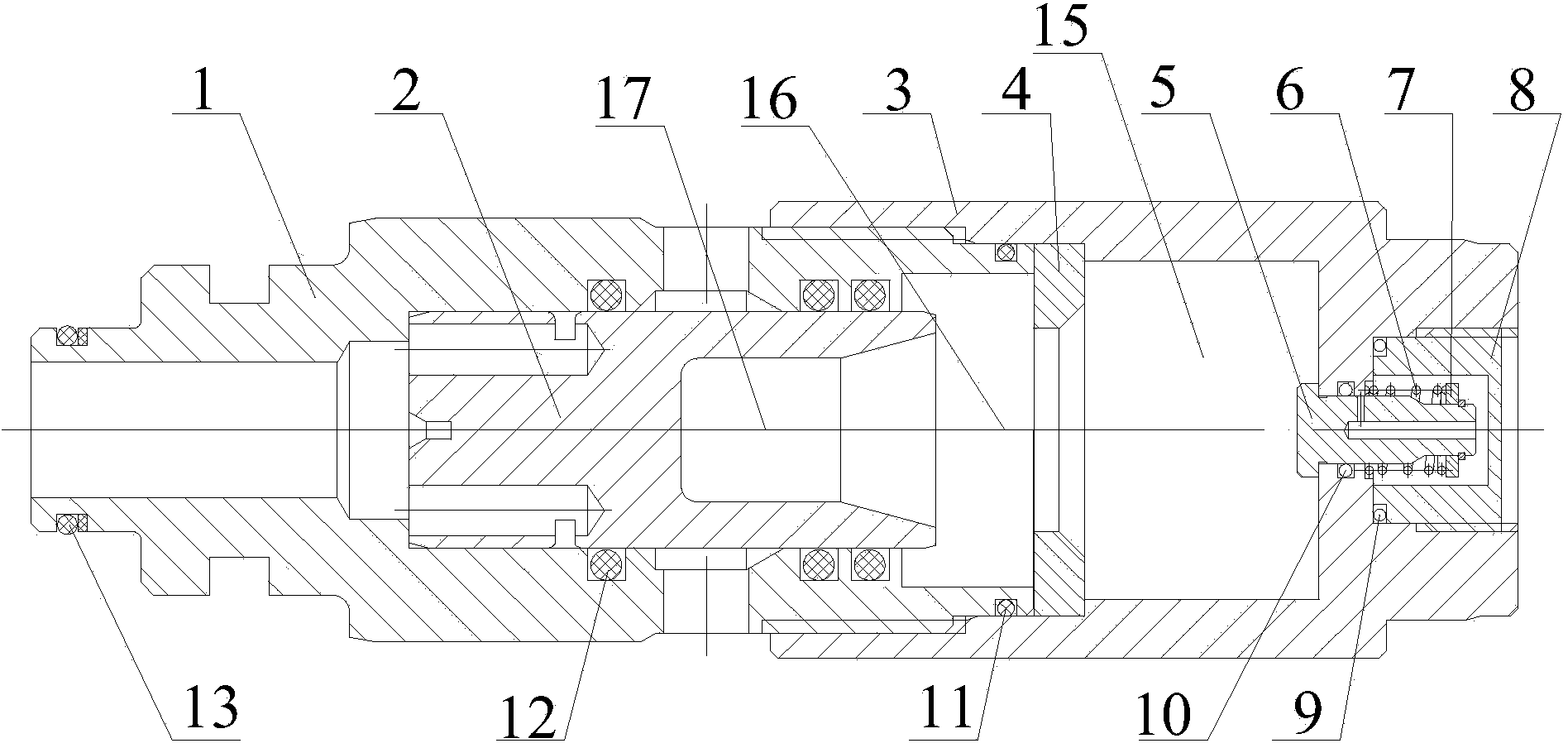

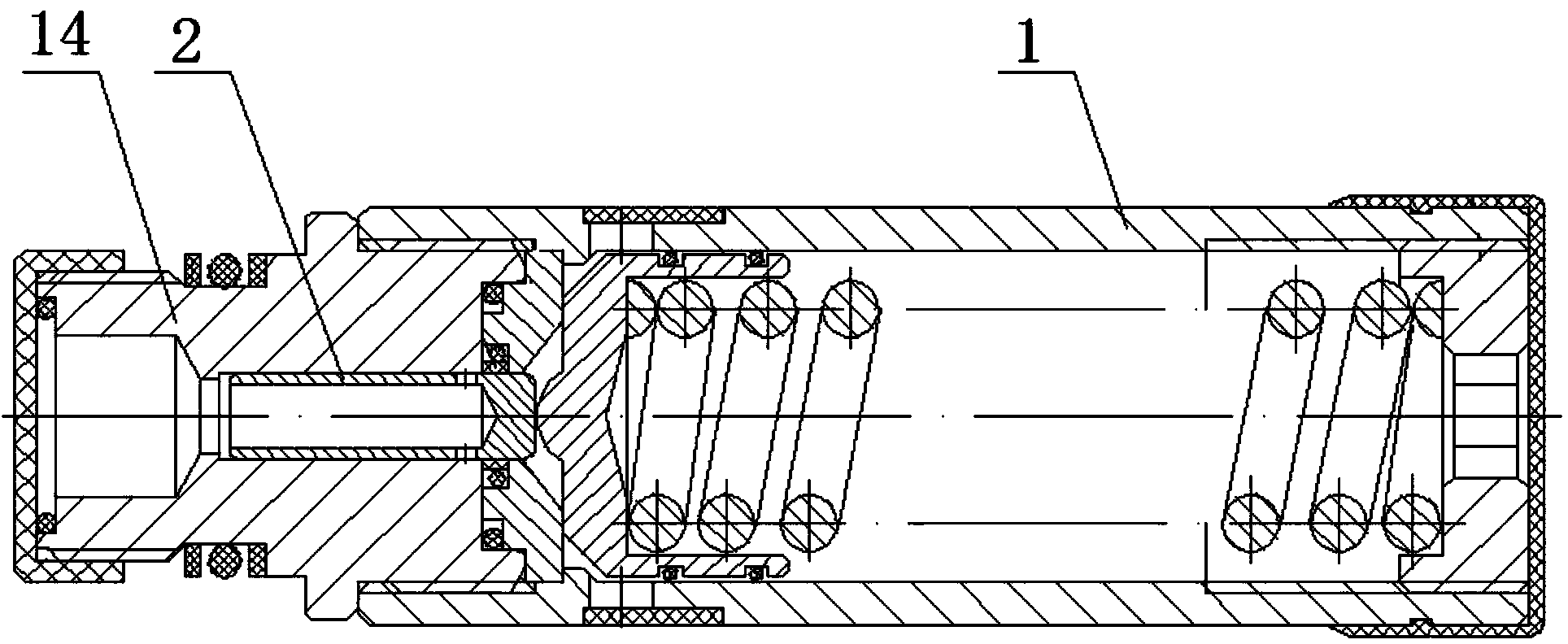

[0009] Such as figure 1 Shown is a kind of nitrogen safety valve for coal mine fully mechanized mining hydraulic support of the present invention, comprises columnar valve housing 1 and valve core 2, and the valve housing 1 of this safety valve has the valve body of safety valve in the prior art The function and the structure are similar, and the valve housing and the valve body are integrally formed in the prior art. The spool 2 of the safety valve is built in the valve hole of the valve casing 1, and an unloading hole is provided on the outer wall of the spool 2 and the valve casing 1. One end of the valve casing 1 is connected with the oil cylinder of the hydraulic support, and the other end is connected with a One end of the screw sleeve 3 is connected, the other end of the screw sleeve 3 is closed, the screw sleeve 3 is columnar, the valve housing 1 has an oil inlet hole, and the screw sleeve 3 has a gas storage chamber 15, and nitrogen gas is stored in the gas storage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com