Pressure releasing automatic reset air shaft anti-explosion cover

A technology of automatic reset and explosion-proof cover, which is used in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc. It can solve problems such as damage to explosion-proof cover, affecting underground rescue work, etc., to achieve uniform impact force, equalize pressure, and reduce time. and human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

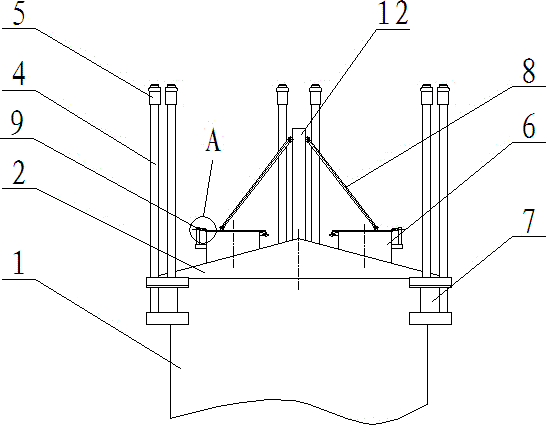

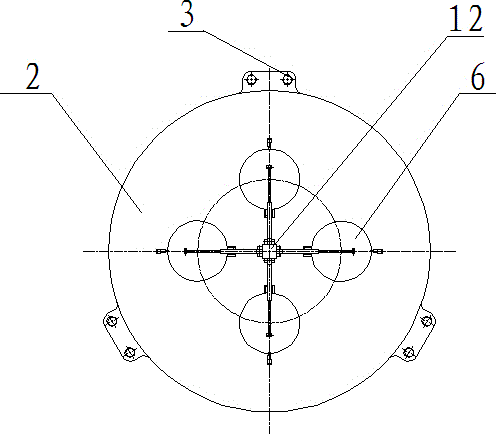

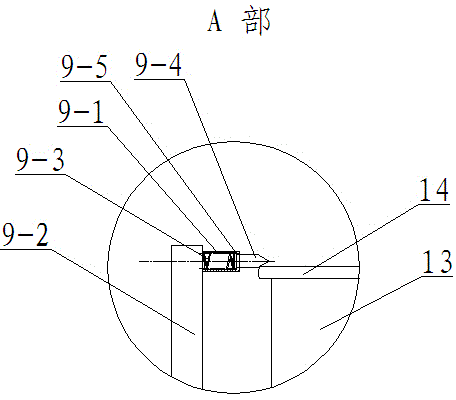

[0014] Such as figure 1 As shown in -5, the present invention mainly includes a well cover 2 arranged on the wellhead 1, three guide sleeves 3 are connected to the outer periphery of the well cover 2 along the circumferential direction, and two guide pillars 4 are respectively inserted in each guide sleeve 3, each The lower ends of the guide pillars 4 are respectively fixed at the position of the wellhead 1, and the top ends of each guide pillar 4 are respectively provided with elastic limit blocks 5. The middle part above the well cover 2 is connected with a column 12 and four pressure relief devices 6 , each pressure relief device 6 is arranged on the outside of the column 12 along the circumferential direction, and each pressure relief device 6 is respectively connected with a locking mechanism 9 . Each pressure relief device 6 includes a pressure relief cylinder 13 respectively, the top of each pressure relief cylinder 13 is hinged cover door 14 respectively, and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com