Substrate bonding process and substrate components to be bonded

A technology for bonding substrates and substrates, applied in optics, instruments, nonlinear optics, etc., can solve the problems of corroding circuit metal wires, loss, acid liquid entry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

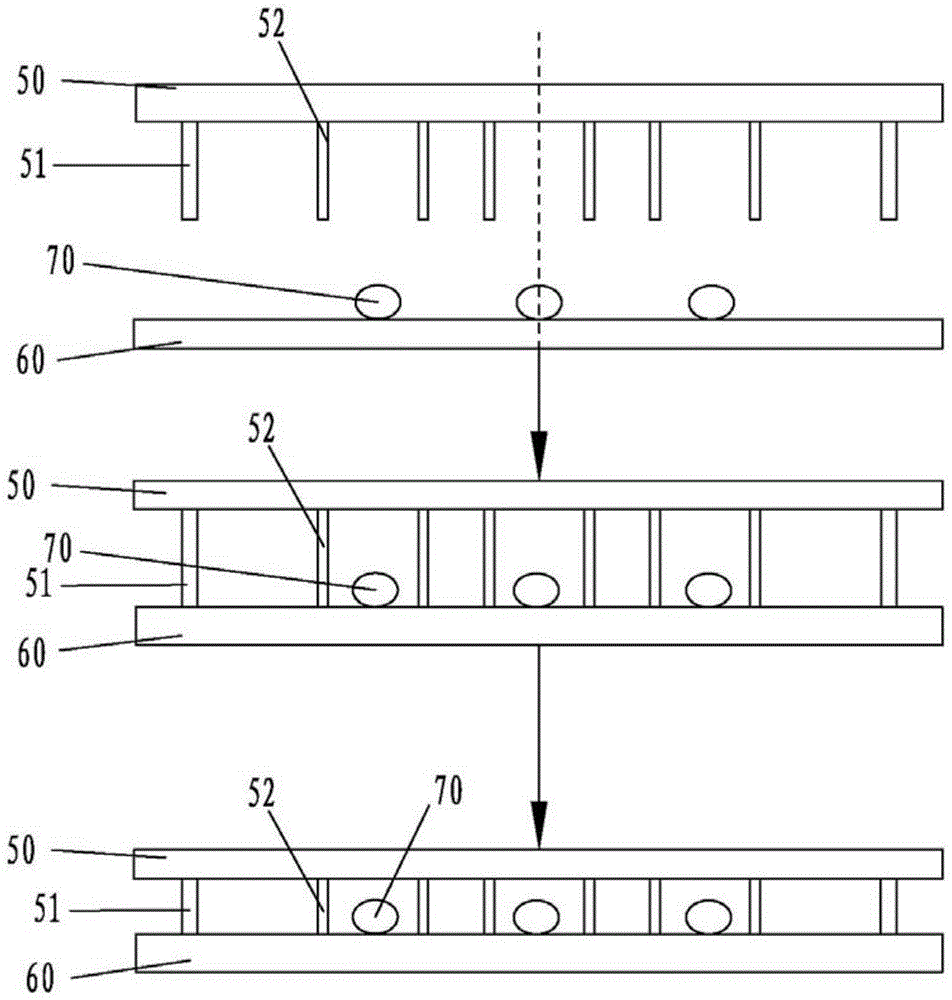

[0075] Such as Figure 5 As shown, Embodiment 1 of the substrate bonding process for forming a liquid crystal panel of the present invention includes:

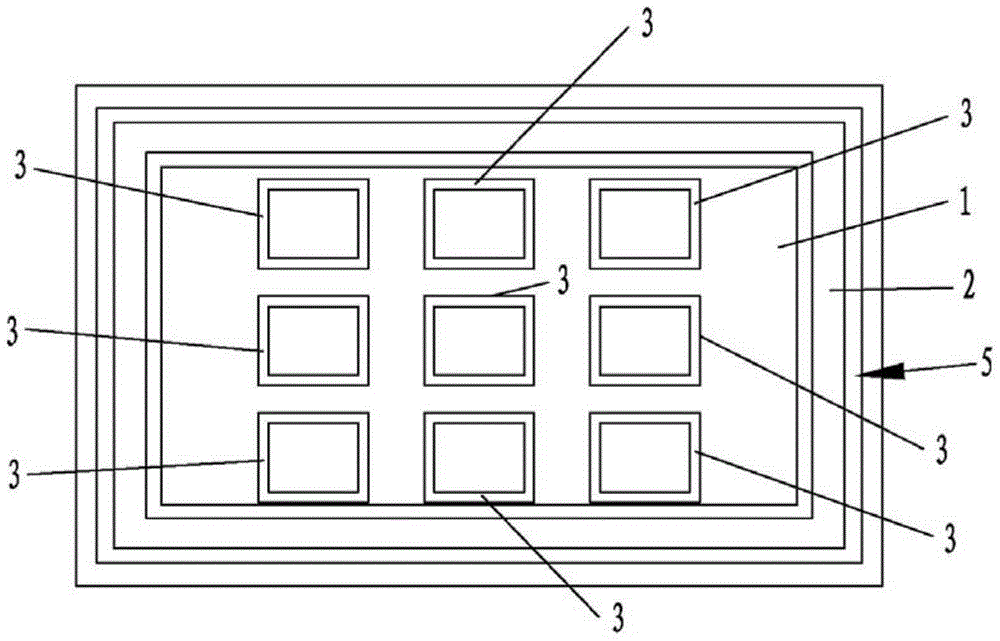

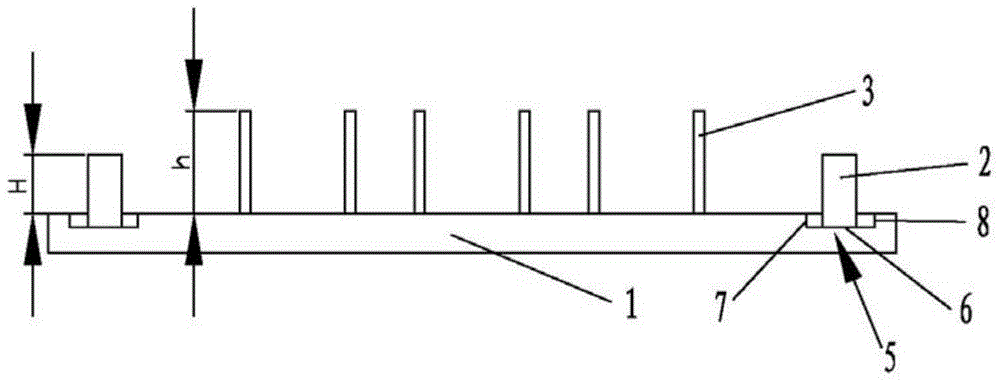

[0076] A peripheral plastic frame 20 is arranged on the surface of the first substrate 10, and a box-shaped plastic frame 30 for sealing liquid crystals is arranged inside the peripheral plastic frame 20. The height of the box-shaped plastic frame 30 is greater than the height of the peripheral plastic frame 20;

[0077] The first substrate 10 is opposite to the second substrate 100, and the side of the first substrate 10 provided with the peripheral plastic frame 20 and the box-forming plastic frame 30 is opposite to the second substrate 100;

[0078] removing the gas between the first substrate 10 and the second substrate 100;

[0079] The first substrate 10 and the second substrate 100 are preliminarily bonded, the box-forming plastic frame 30 is in contact with the second substrate 100, and there is a gap between the peri...

Embodiment 2

[0087] Such as Image 6 As shown, Embodiment 2 of the substrate bonding process for forming a liquid crystal panel of the present invention includes:

[0088] In the middle part of the surface of the first substrate 10', a box-forming plastic frame 30' for sealing liquid crystals is arranged, and a peripheral plastic frame 20' is arranged on the edge of the surface of the second substrate 100', and the height of the box-forming plastic frame 30' is greater than that of the periphery The height of the plastic frame is 20';

[0089] Make the first substrate 10' and the second substrate 100' opposite, the side of the first substrate 10' that is provided with the box plastic frame 30' is opposite to the side that is provided with the peripheral plastic frame 20' of the second substrate 100';

[0090] Excluding the gas between the first substrate 10' and the second substrate 100';

[0091] The first substrate 10' and the second substrate 100' are preliminarily bonded, the box-for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com