A Tunnel Model Test Method with Variable Rigidity of Lining Structure Joints

A tunnel model and test method technology, applied in teaching models, strength characteristics, measuring devices, etc., can solve problems such as changes, inability to provide accurate and reliable test basis for tunnel engineering design, construction and maintenance, and low reliability. Test the effect of accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

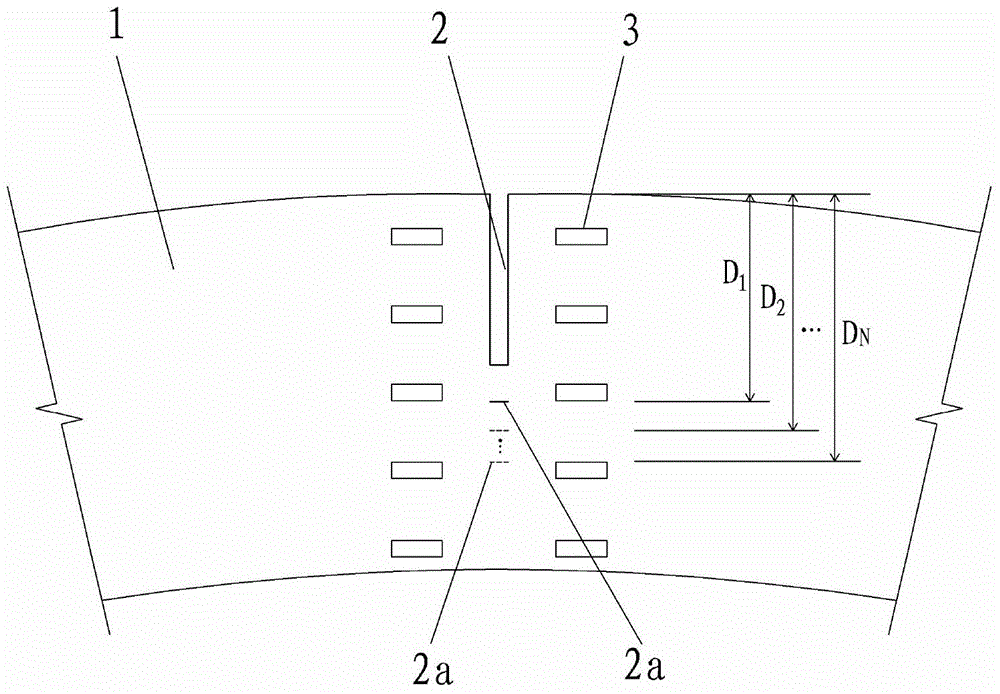

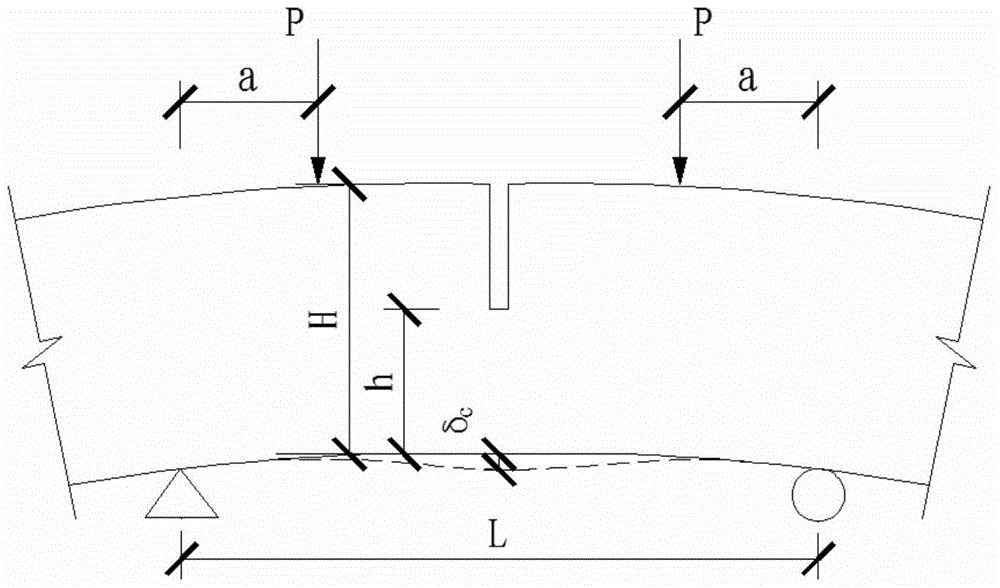

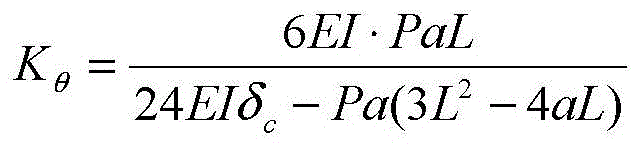

[0019] figure 1 It is shown that a specific embodiment of the present invention is a tunnel model test method with variable stiffness of lining structure joints, the method of which is:

[0020] A. Model making: Make a shield tunnel model 1 with gypsum, and form grooves 2 for simulating the initial stiffness of the segment joints on the outer peripheral surface of the shield tunnel model 1;

[0021] B. The test instrument is arranged on both sides of the groove 2 to arrange strain gauges 3 or displacement gauges;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com