Preparation method of steel welding seam heat affected zone simulation sample

A heat-affected zone and simulated sample technology, which is applied in the field of metal material welding, can solve problems such as lack, impossibility of testing, small sample size, etc., and achieve the effect of improving accuracy, large size, and consistent heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

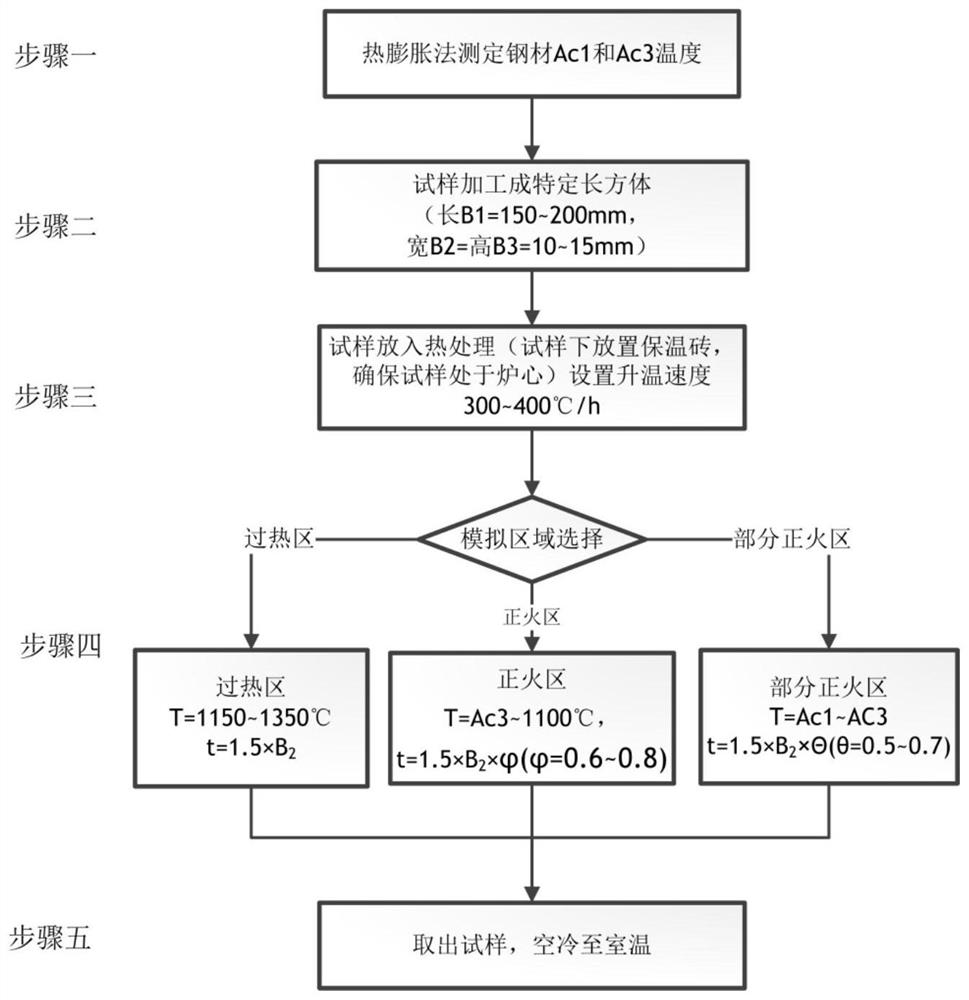

[0028] like figure 1 , the preparation method of the heat-affected zone simulation sample of the steel weld of the present invention comprises:

[0029] S1: The transformation temperatures Ac1 and Ac3 of the steel were measured by the thermal expansion method; the heating rate was set to 150°C / h.

[0030] S2: The steel is processed into regular hexahedral samples of preset size, and then placed in a box-type muffle furnace heat treatment furnace to set the heat treatment parameters. In general, the length B of the sample 1 =100~200mm, width B 2 =10~15mm, thickness (height) B 3 with wide B 2 equal. The maximum heating temperature of the heat treatment furnace is ≥1300℃. There is an insulating brick under the sample, and the sample is in the center of the heat treatment furnace. The heating rate is 300 to 400°C / h.

[0031] S3: Set the peak temperature and peak temperature holding time according to the heat affected zone area to be simulated and prepared. Peak temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com