Button assembly

A button and component technology, which is applied in the field of testing button components, can solve problems such as incorrect assembly, button deformation, and inconsistent button positions, and achieve the effects of avoiding incorrect assembly, increasing mechanical strength, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

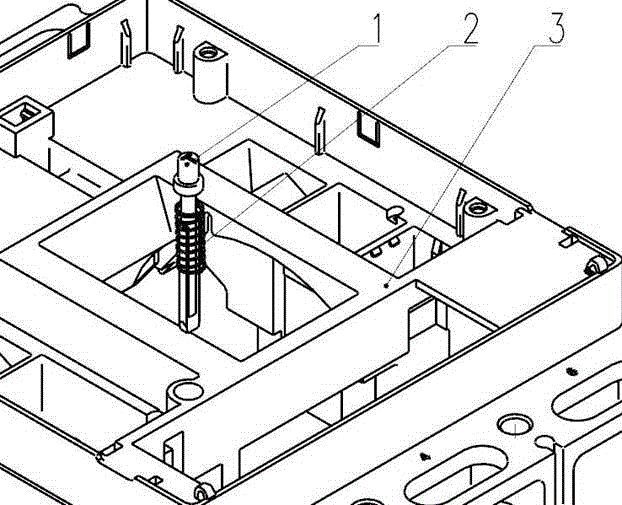

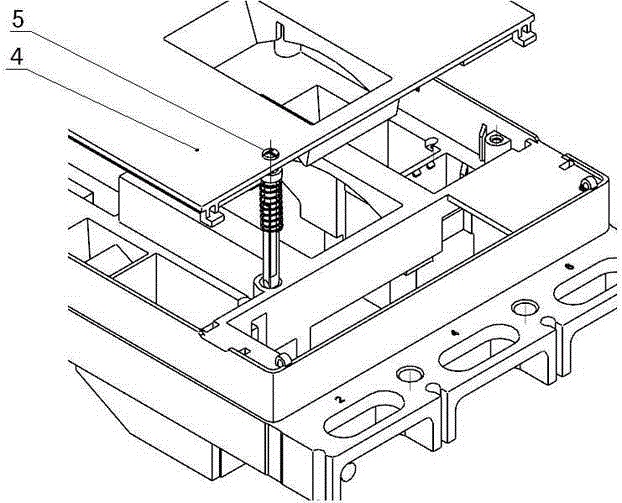

[0030] The structure of a button assembly of the present invention is as figure 1 , figure 2 As shown, it includes button 1, spring 2 and housing part 3. A panel 4 is arranged on the shell part 3, and a feature hole is provided between the shell part 3 and the panel 4. The spring 2 presses the button 1 and is installed in the feature hole between the shell part 3 and the panel 4, so that the button 1 can be pressed into a predetermined The upper and lower parts of the feature hole are respectively provided with an upper through hole 13 and a lower through hole 14 that allow the button 1 to pass through and rotate. The groove 17 that the bottom of the button 1 is embedded.

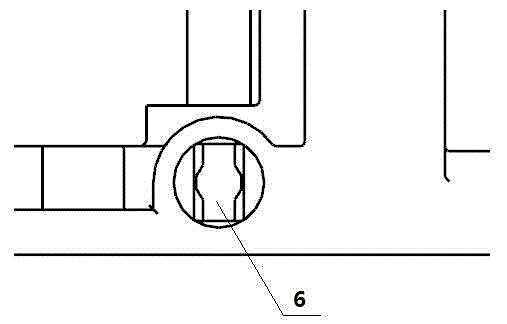

[0031] The above-mentioned characteristic holes include the upper hole 6 and the lower hole 7 of the housing. The upper hole 6 of the housing is a rectangular columnar hole with arc-shaped protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com