Fuel cell structure with self-humidifying function

A fuel cell and fuel cell unit technology, applied in the direction of fuel cells, fuel cell additives, fuel cell grouping, etc., can solve the problems of increasing the size and weight of fuel cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

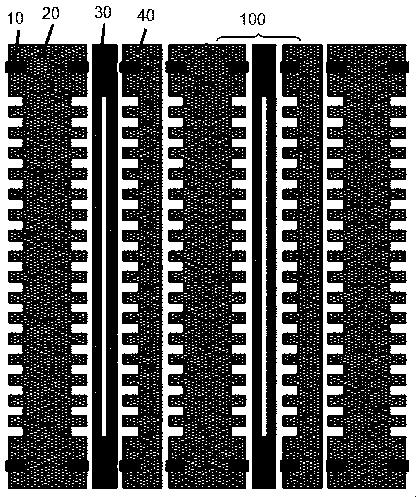

[0033] A conventional complete single fuel cell includes a sealing ring 10, a water oxygen plate 20, a membrane electrode 30 and a single hydrogen plate 40, such as figure 1 shown.

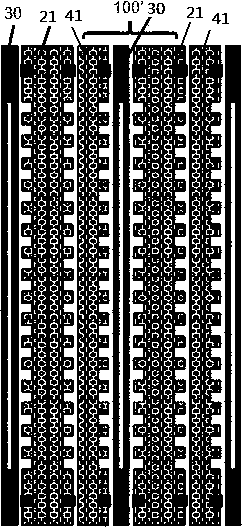

[0034] In this example, if figure 2 As shown, a microporous plate fuel cell structure with hydrogen side and oxygen side self-humidification function is provided, and the cell structure includes several fuel cell units connected in series, wherein each complete single fuel cell includes:

[0035] Sealing rings 10 placed at both ends of the fuel cell unit;

[0036] a membrane electrode 30 disposed in the middle of the fuel cell unit; and

[0037] The microporous water-oxygen humidification pole plate 21 and the microporous monohydrogen humidification pole plate 41 are respectively arranged on both sides of the membrane electrode 30 .

[0038] Fuel cell humidification water comes from cooling water with a temperature of 75°C to 80°C. The humidifying water passes through the cooling water fl...

Embodiment 2

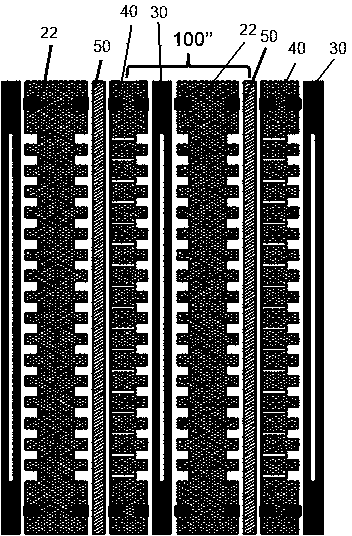

[0041] Such as image 3 As shown, another kind of porous plate fuel cell structure with oxygen side self-humidification function provided by the present invention, this cell structure includes several fuel cell units connected in series, wherein each complete single fuel cell includes:

[0042] Sealing rings 10 placed at both ends of the fuel cell unit;

[0043] Membrane electrode 30 arranged in the middle of the fuel cell unit;

[0044] The hydrogen pole plate and the oxygen pole plate with self-humidification structure are respectively arranged on both sides of the membrane electrode 30 .

[0045] The oxygen plate with self-humidification structure is a combination of porous single oxygen humidification plate 22 and membrane 50, and the porous single oxygen humidification plate 22 is located between the membrane electrode 30 and the membrane 50; Plate 40, membrane electrode 30, porous single-oxygen humidification plate 22 and membrane 50 are assembled in sequence to form a...

Embodiment 3

[0050] Such as Figure 4 As shown, a porous plate fuel cell structure with hydrogen side and oxygen side self-humidification function is provided. Water plate 60; wherein each complete single fuel cell comprises:

[0051] Seal rings 10 placed at both ends of the fuel cell unit;

[0052] Membrane electrode 30 arranged in the middle of the fuel cell unit;

[0053] An oxygen plate with a self-humidification structure and a hydrogen plate with a self-humidification structure respectively arranged on both sides of the membrane electrode 30;

[0054] Wherein, the oxygen pole plate is a combination of porous single oxygen humidification pole plate 22 and membrane 50; the hydrogen pole plate is a combination of porous single hydrogen humidification pole plate 42 and membrane 50; in the battery structure, according to the membrane 50. A single cell is assembled in sequence of the porous single oxygen humidification pole plate 22, the membrane electrode 30, the porous single hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com