Transparent composite substrate and display element substrate

A composite substrate, transparent technology, used in textiles, fabrics, instruments, etc., can solve the problem of lack of optical properties, and achieve uniform, excellent optical properties, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

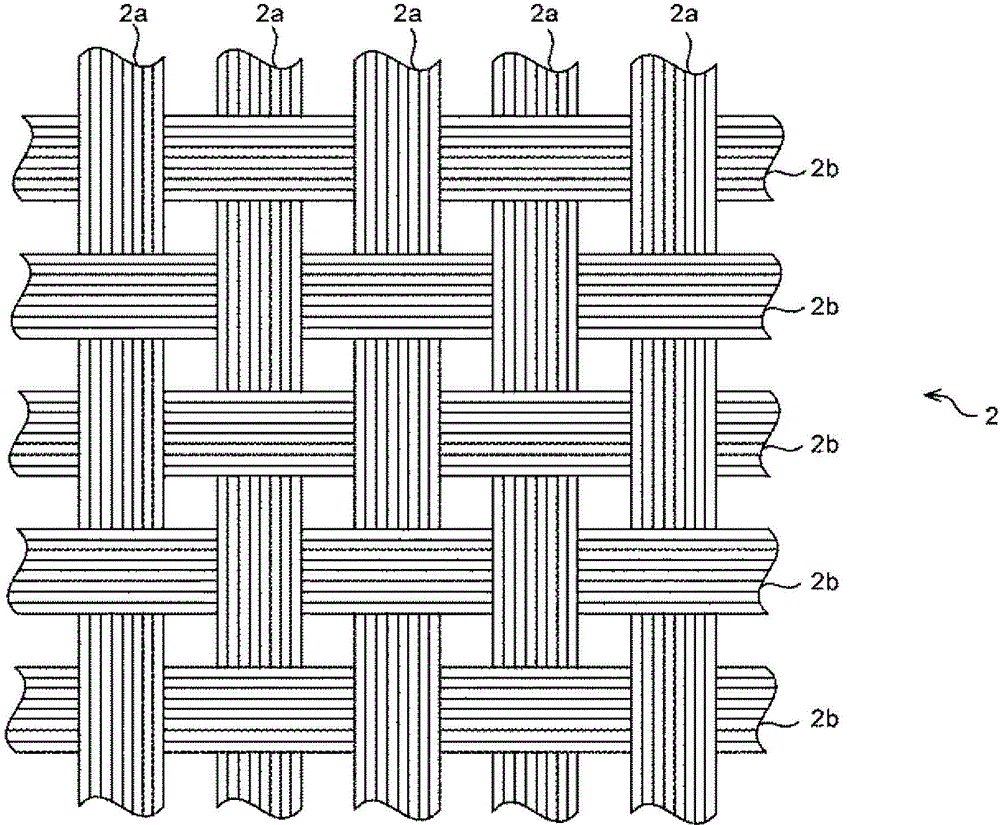

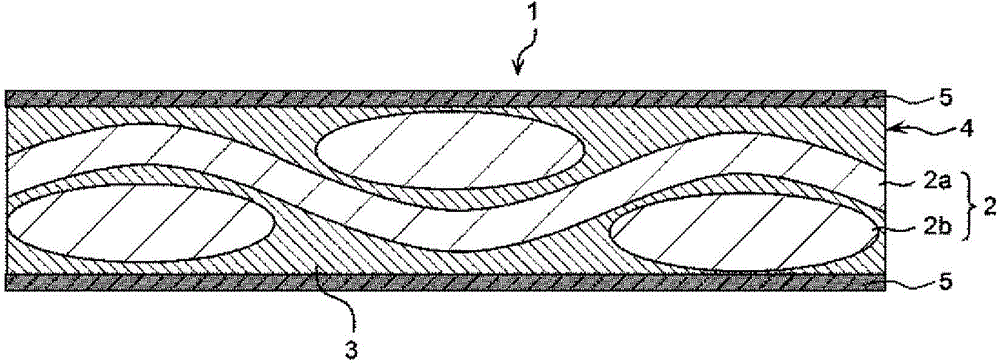

[0193] (1) Preparation of glass cloth

[0194] First, as a glass cloth, a 100 mm square NE glass-based glass cloth (average thickness 95 μm, average wire diameter 9 μm) was prepared. After immersing this in benzyl alcohol (refractive index: 1.54), acetoxyethoxyethane (refractive index: 1.406) was gradually added to this benzyl alcohol in small amounts. Then, each time the refractive index of benzyl alcohol was changed, a glass cloth was placed over the fluorescent lamp, and it was confirmed whether the glass cloth became substantially transparent. In addition, the refractive index of the mixed solution when a substantially transparent portion appeared on the glass cloth was measured.

[0195] The difference between the refractive index of the mixed liquid when a substantially transparent portion first appeared and the refractive index of the mixed liquid when a substantially transparent portion appeared last was defined as the difference in refractive index of the glass cloth...

Embodiment 2A~12A

[0211] (Examples 2A to 12A and Comparative Examples 1A to 4A)

[0212] Except having changed the manufacturing conditions as shown in Tables 1 and 2, it carried out similarly to Example 1A, respectively, and obtained the transparent composite board|substrate.

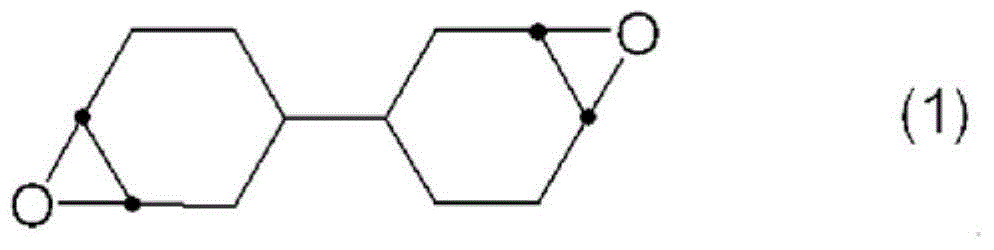

[0213] In addition, in Examples 2A, 3A, 4A, 8A, 12A and Comparative Examples 2A, 4A, the hydrogenated biphenyl type alicyclic epoxy resin (E-BP manufactured by Daicel Chemical Industry Co., Ltd.) used as a resin monomer , Tg:>250°C) has the structure of the above chemical formula (1). In addition, the refractive index of E-BP after crosslinking was 1.522.

[0214] In addition, in Examples 3A, 8A and Comparative Example 2A, T glass-based glass cloth (average thickness 95 μm, average wire diameter 9 μm) was used as the glass cloth; in Example 5A, S glass-based glass cloth was used as the glass cloth. Cloth (average thickness 95 μm, average wire diameter 9 μm); in Comparative Examples 3A and 4A, E-glass glass cloth (aver...

Embodiment 1B~12B、 comparative example 1B~5B

[0222] In Example 1B, except having made content of the glass cloth in a composite layer into 60 mass %, it carried out similarly to Example 1A, and obtained the transparent composite board|substrate. In addition, in Examples 2B to 12B and Comparative Examples 1B to 5B, except that the production conditions were changed as shown in Tables 3 and 4, transparent composite substrates were obtained in the same manner as in Example 1B, respectively.

[0223] In addition, the 5% weight reduction temperature of the alicyclic epoxy resin or alicyclic acrylic resin which is the main component contained in the resin material is calculated as Td [° C.], and the melting point of the inorganic material constituting the gas barrier layer as Td [° C.] Tables 3 and 4 show Tm-Td at Tm [°C].

[0224] In addition, in Examples 3B, 8B and Comparative Example 2B, T glass-based glass cloth (average thickness 95 μm, average wire diameter 9 μm) was used as the glass cloth; in Example 5B, S glass-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com