Transparent composite substrate and display element substrate

A composite substrate and transparent technology, applied in the direction of textiles and papermaking, chemical instruments and methods, synthetic resin layered products, etc., can solve problems such as lack of optical properties, achieve uniform and excellent optical properties, high reliability, suppress The effect of reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A)

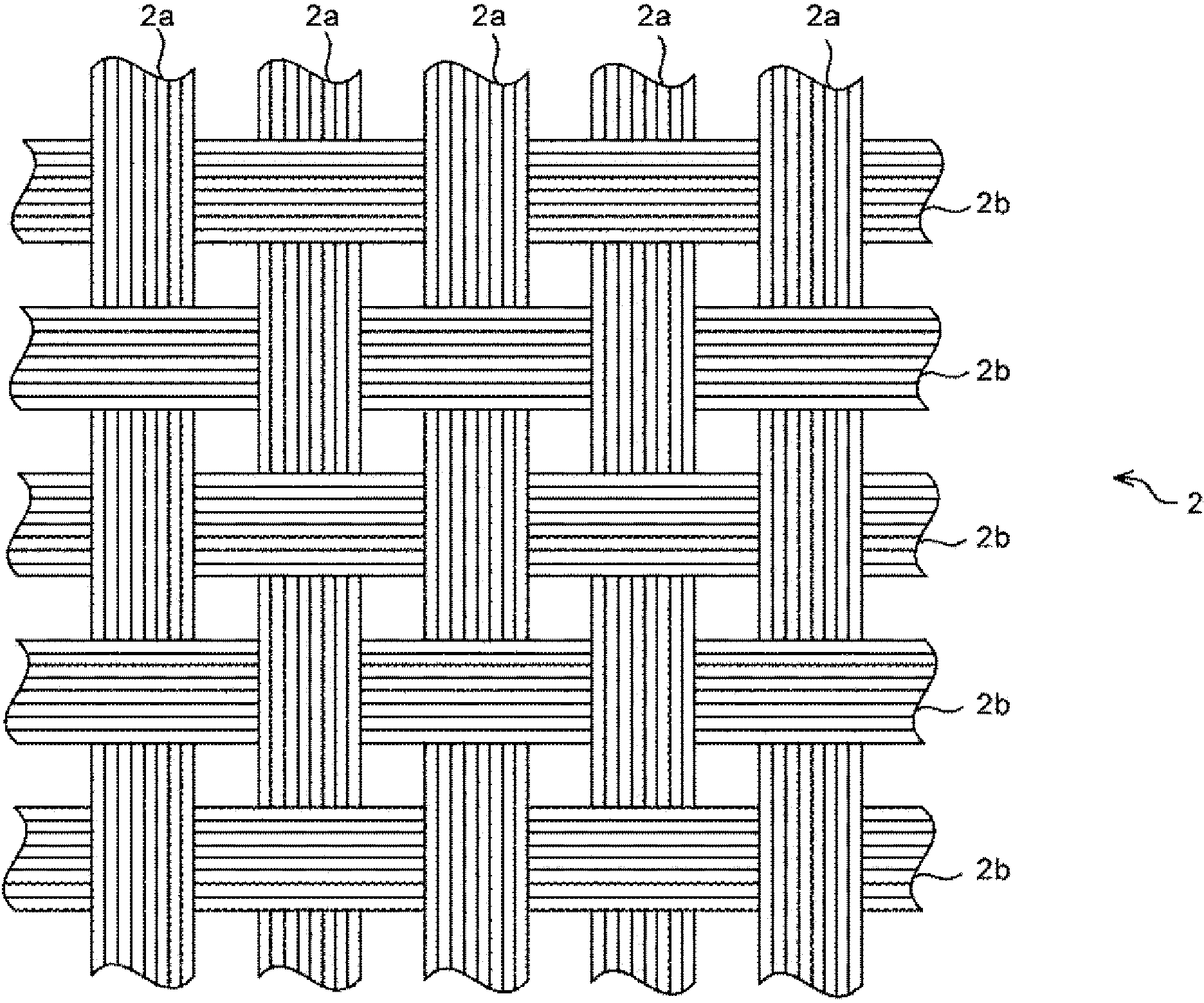

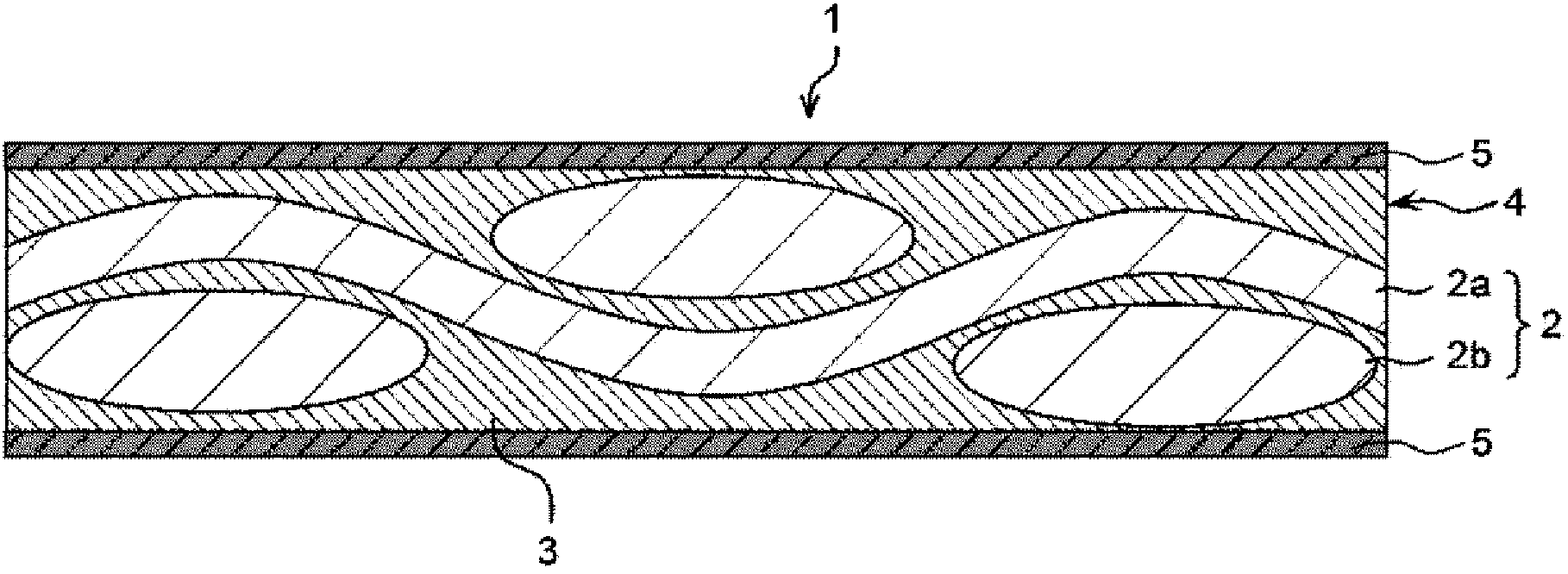

[0188] (1) Preparation of glass cloth

[0189] First, as a glass cloth, a 100 mm square NE glass-based glass cloth (average thickness 95 μm, average wire diameter 9 μm) was prepared. After immersing this in benzyl alcohol (refractive index 1.54), acetoxyethoxyethane (refractive index 1.406) was added to the benzyl alcohol in small amounts. Then, each time the refractive index of benzyl alcohol was changed, a glass cloth was covered on the fluorescent lamp, and it was confirmed whether the glass cloth was substantially transparent. In addition, the refractive index of the mixed solution when a substantially transparent portion appeared on the glass cloth was measured.

[0190] The difference between the refractive index of the mixed liquid when a substantially transparent portion first appeared and the refractive index of the mixed liquid when a substantially transparent portion appeared last was defined as the difference in refractive index of the glass cloth. In addition, t...

Embodiment 2A~9A

[0207] (Examples 2A to 9A and Comparative Examples 1A to 5A)

[0208] Except having changed the manufacturing conditions as shown in Table 1 and 2, it carried out similarly to Example 1A, respectively, and obtained the transparent composite board|substrate. In addition, the average thickness of the composite layer is shown in Tables 1 and 2.

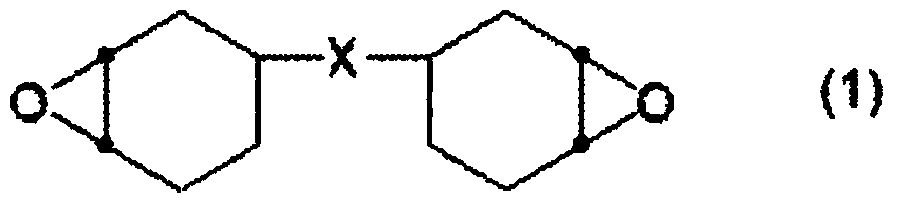

[0209] In addition, in Examples 2A, 3A, 4A, 8A, 9A and Comparative Example 2A, the hydrogenated biphenyl type alicyclic epoxy resin (E-BP, Tg manufactured by Daicel Chemical Industries, Ltd.) used as a resin monomer : >250° C.) has the structure of the following chemical formula (2). In addition, the refractive index of E-BP after crosslinking was 1.522.

[0210]

[0211] In addition, in Examples 3A, 8A, 9A and Comparative Example 2A, T glass-based glass cloth (average thickness 95 μm, average wire diameter 9 μm) was used as the glass cloth, and in Example 5A and Comparative Examples 3A and 4A, as As the glass cloth, S glass-type g...

Embodiment 1B~10B and comparative example 1B~6B

[0219] In Example 1B, except having made the content of the glass cloth in a composite layer into 57 mass %, it carried out similarly to Example 1A, and obtained the transparent composite board|substrate. Moreover, in Examples 2B-10B and Comparative Examples 1B-6B, except having changed manufacturing conditions as shown in Table 3 and 4, it carried out similarly to Example 1B, respectively, and obtained the transparent composite board|substrate. In addition, the average thickness of the composite layer is shown in Tables 3 and 4.

[0220] In addition, in Examples 3B and 8B and Comparative Examples 2B and 6B, T glass-based glass cloth (average thickness 95 μm, average wire diameter 9 μm) was used as the glass cloth, and in Example 5B and Comparative Examples 3B and 4B, as As the glass cloth, S glass-type glass cloth (average thickness 95 μm, average wire diameter 9 μm) was used.

[0221] In addition, regarding the average refractive index of the glass cloth used, the refractiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com