Manufacturing method of one-time absorber

A manufacturing method and technology for an absorbent body, which can be used in absorbent pads, medical science, bandages, etc., can solve the problems of eczema, erythema, prone to faults, reverse osmosis, etc., to reduce urine extravasation, increase utilization, and Eczema reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

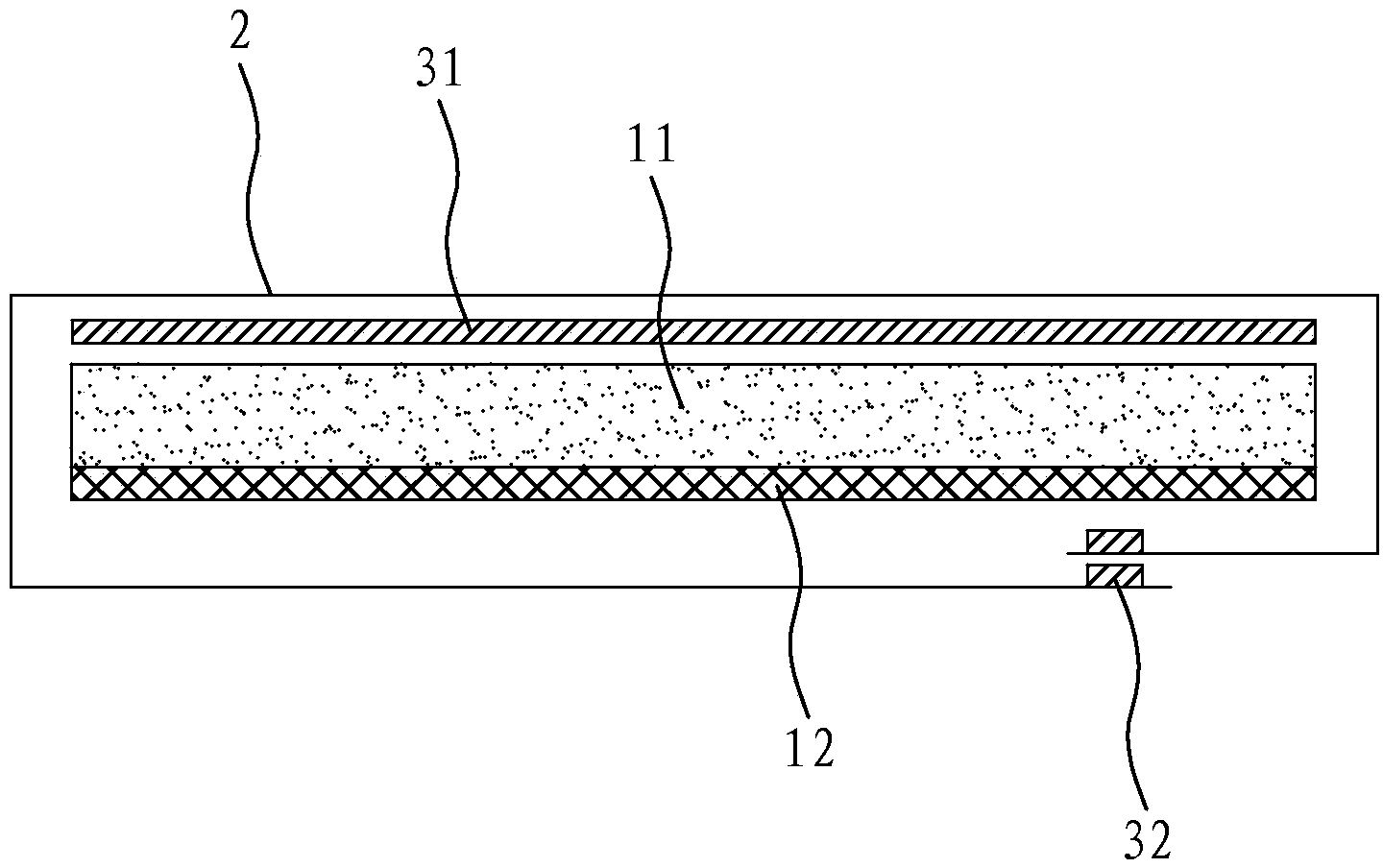

[0015] refer to figure 1 , the present embodiment provides a manufacturing method of a disposable absorbent body, comprising the following steps:

[0016] The first step is to pulverize the raw wood pulp fibers by hammering and output;

[0017] In the second step, the output wood pulp fibers are divided, 10% of the wood pulp fibers are directly input into the mold cavity of the mold wheel as the bottom layer of the absorbent core, and the rest of the wood pulp fibers are mixed with polymers and then input into the mold cavity of the mold wheel As the upper layer of the absorbent core, it is output after molding;

[0018] The third step is to apply the fixed hot melt adhesive on both sides and the middle of the absorbent core wrapping material respectively, and use the absorbent core wrapping material to wrap the absorbent core, and make the fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com