Scanning leakage detection efficient negative-pressure exhaust hood

An exhaust hood, high-efficiency technology, applied in the direction of dust removal, cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effects of efficient exhaust, environmental protection, and safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

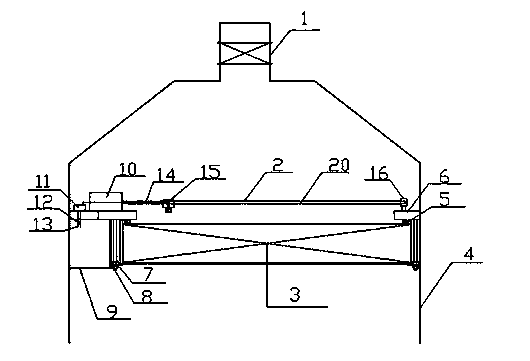

[0020] A scanning leak detection high-efficiency negative pressure exhaust hood, including a box body 4, the box body 4 is a hollow structure with upper and lower ends open, the diameter of the upper port is smaller than the diameter of the lower port; the upper port of the box body 4 A biological sealer 1 is built in, and a high-efficiency filter 3 is built in its hollow part. Both sides of the high-efficiency filter 3 are fixed by a fixed pressing plate 7, and the lower end of the fixed pressing plate 7 is fixed with a set screw 8.

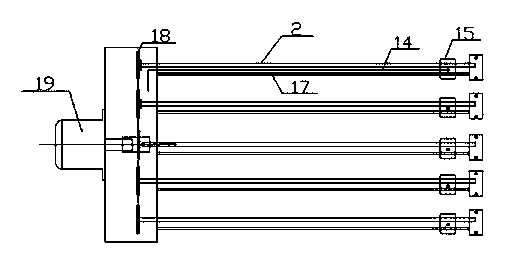

[0021] A sealing frame 6 is provided above the connection between the high-efficiency filter 3 and the fixed pressure plate 7, and a liquid tank sealant 5 is also provided between the sealing frame 6 and the high-efficiency filter 3. The sealing function can prevent the gas from overflowing through the gap between the high-efficiency filter and the fixed pressure plate. On one of the sealing frames 6, a gas collecting box 11 and a transmission b...

Embodiment 2

[0027] The difference from Embodiment 1 is that a dedicated exhaust fan is installed on the pipeline at the upper port of the exhaust hood.

[0028] This kind of exhaust hood is a dynamic scanning leak detection high-efficiency negative pressure exhaust hood. The gas filtered through the scanning leak detection and high-efficiency filtration is discharged through the pipeline through a dedicated exhaust fan. Influenced by other exhaust equipment, it is more suitable for experiments in atmospheric laboratory operations. Such as centrifugation, packaging, etc.

[0029] The above two high-efficiency negative pressure exhaust hoods for scanning leak detection adopt linear scanning leak detection method to conduct in-situ leak detection on high-efficiency filters, and adopt the method of synchronous disinfection with the laboratory to disinfect and sterilize high-efficiency filters. And it can display the filtration resistance of the high efficiency filter in real time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com