Vertically compensated stirring friction welding technique

A technology of vertical compensation and friction stirring, which is applied in the direction of welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems that the quality of weldments cannot be guaranteed, achieve good welding effect, good quality, and solve the effect of excessive weld gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

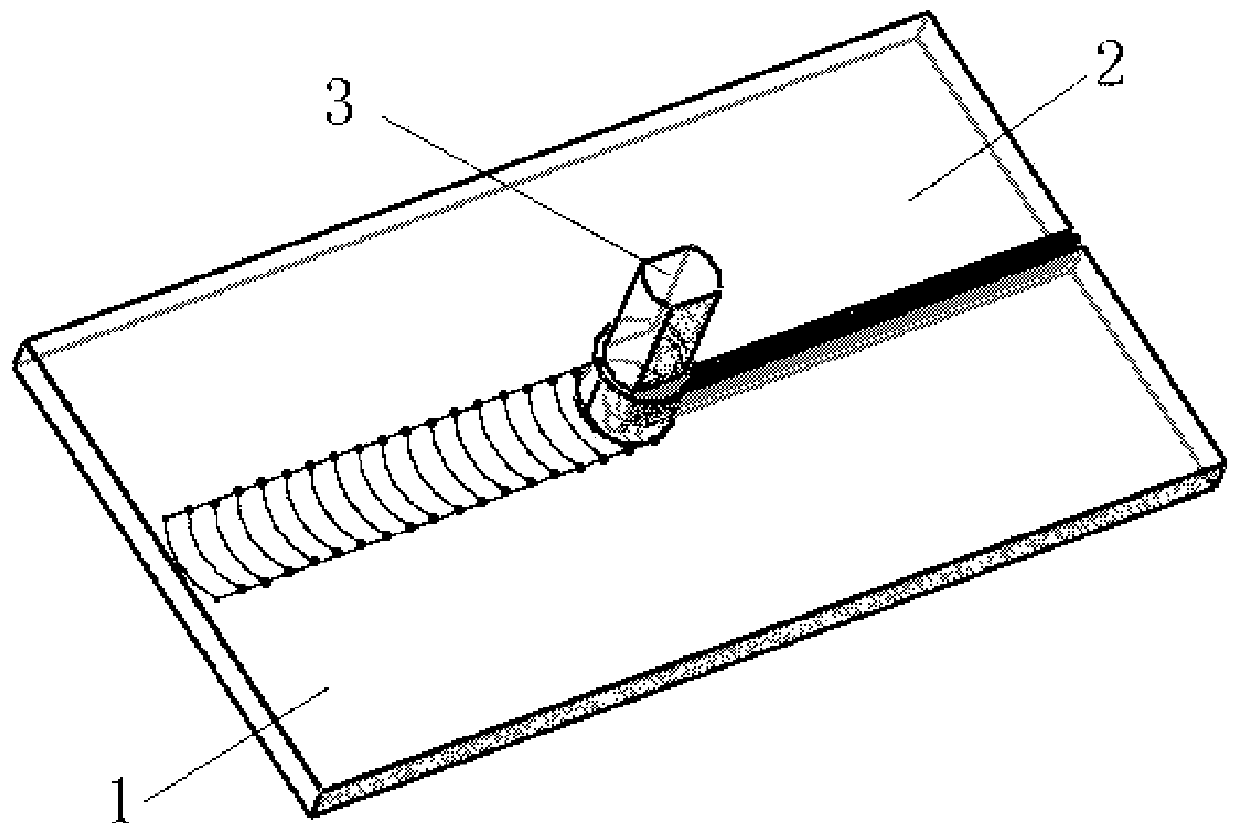

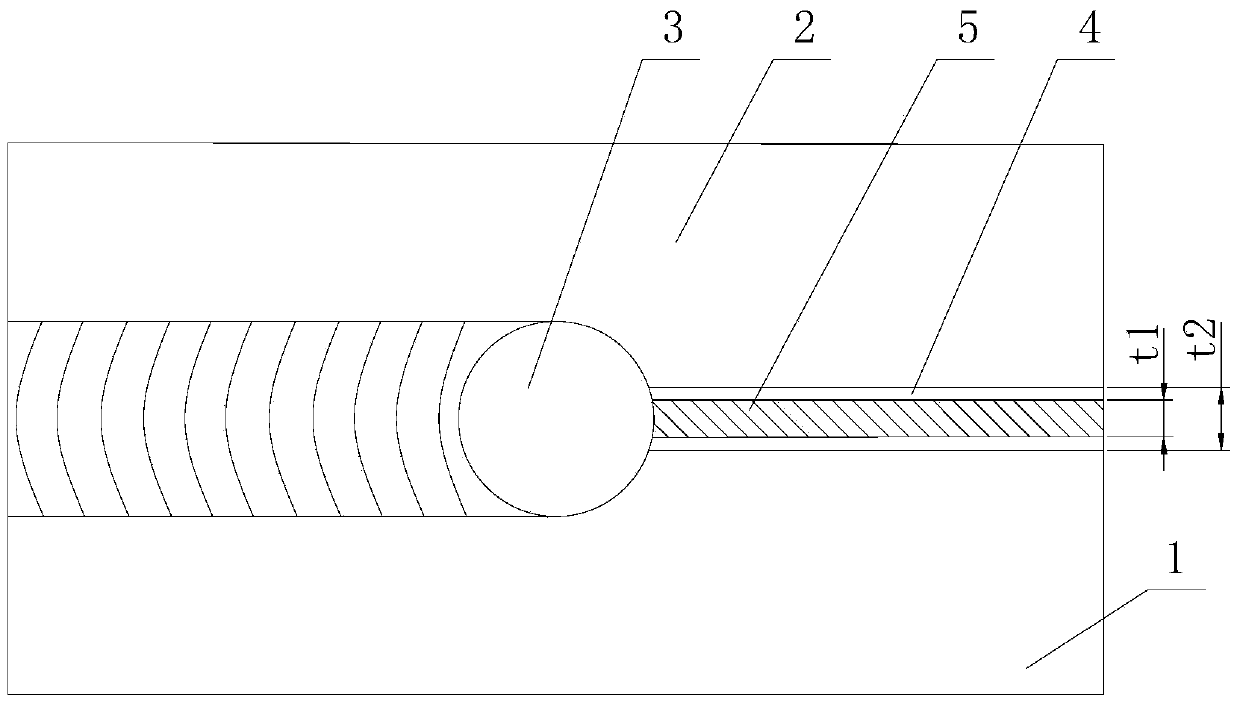

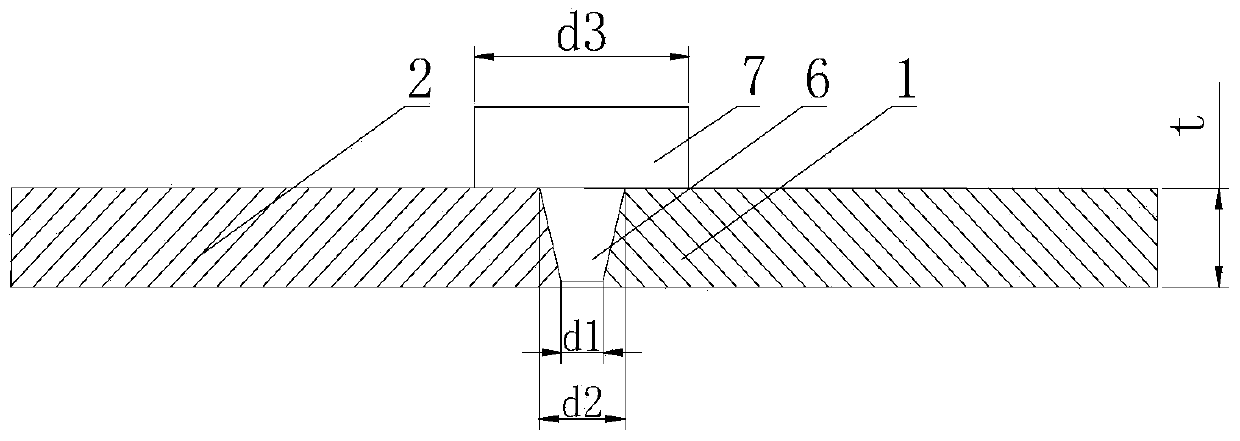

[0042] Such as figure 1 , figure 2 , image 3 As shown, a vertical compensation friction stir welding process method described in this embodiment is realized according to the following steps:

[0043] Step 1. Place the first weldment, the second weldment and the vertical compensation material 5 on the same horizontal plane (that is, combine the first weldment, the second weldment and the vertical compensation material 5), and clamp them with a fixture On the workbench; the first weldment and the second weldment are plates with the same thickness t; the absolute value of the difference between the height of the vertical compensation material 5 and the thickness t of the first weldment or the second weldment is less than 0.3mm , and the gap 4 width t between the first weldment and the second weldment 2 with compensating material 5 width t 1 The difference is less than 1 / 10 of the thickness of the first weldment.

[0044] Step 2, the root diameter d of the stirring needle 6...

Embodiment 2

[0047] In step 2 of this embodiment, the rotation speed of the stirring head 3 is 1500 rpm. Other steps are the same as in Embodiment 1.

Embodiment 3

[0049] In step three of this embodiment, the stirring head 3 moves along the horizontal direction at a speed of 50 mm / min. Other steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com