Spring adding machine

A technology of adding springs and barrels, applied in metal processing, metal processing equipment, hand-held tools, etc., can solve the problems of not being able to identify the state of the spring without feeding, high cost, and the spring is easy to get stuck in the feeding port, etc., to achieve The effect of reducing rework rate, increasing yield rate and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

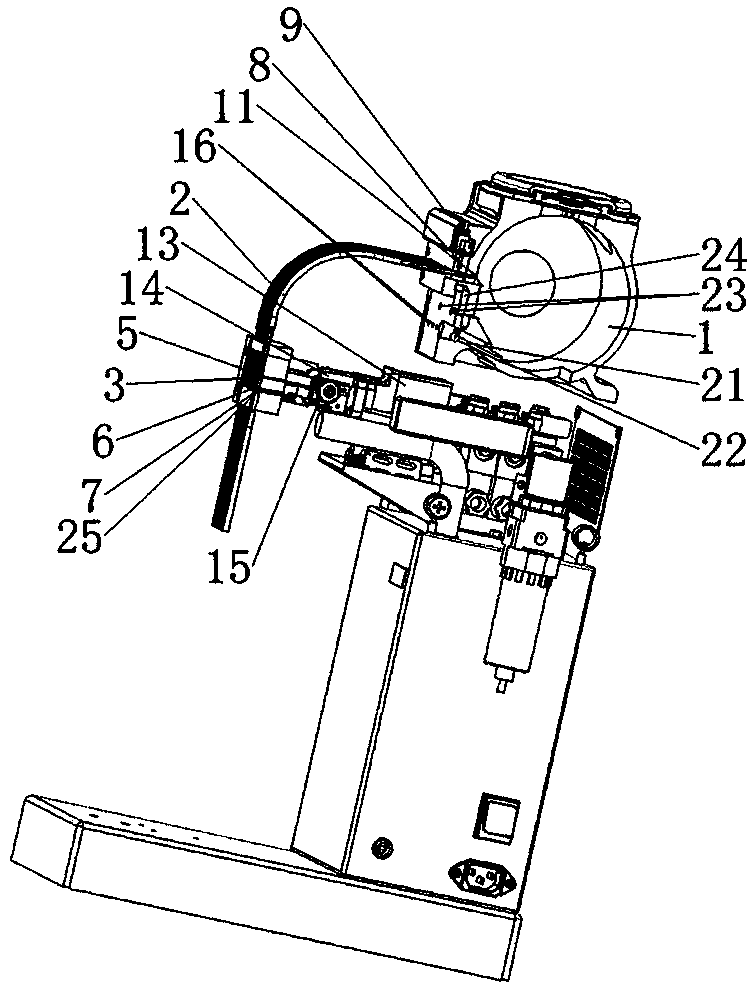

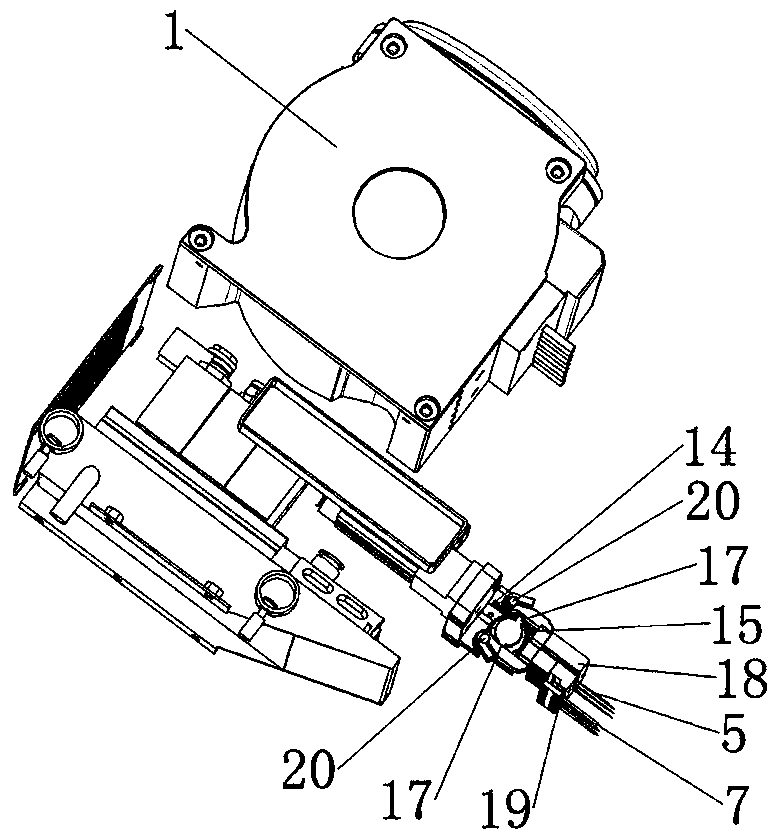

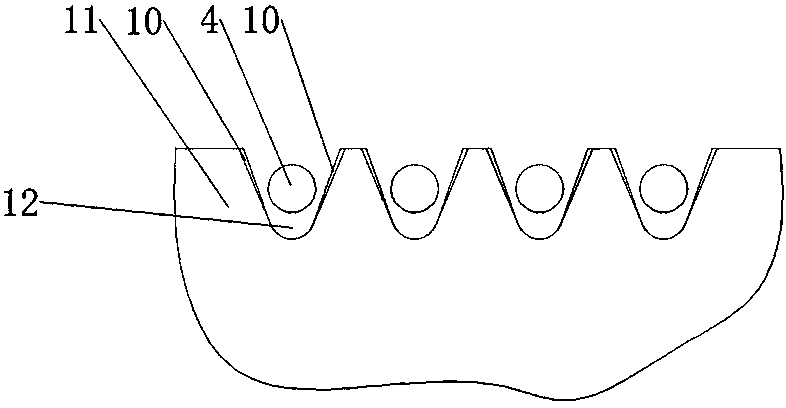

[0010] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0011] refer to figure 1 , figure 2 As shown, the springing machine provided by the present invention includes, including a blowing barrel 1, a forward blowing device, a back blowing device, a plurality of feed pipes 2 and a discharge head 3, wherein the blowing barrel 1 is provided with a feed pipe 2 communicated with the inlet 4, the tail end of the feed pipe 2 has the discharge head 3, the forward blowing device is connected to the blowing cylinder 1, and the reverse blowing device is connected to the inlet 4 in the opposite direction. , the discharge head 3 includes an upper clamping pin 5 and a conductive detection device, the conductive detection device includes a conductive sleeve 6 and a clamping and conductive detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com