Novel multi-cavity flow-balance cold runner structure

A flow balance, multi-cavity technology, applied in the field of mold design, can solve the problem of non-uniform temperature distribution of molten plastic, and achieve the effect of symmetrical temperature distribution and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

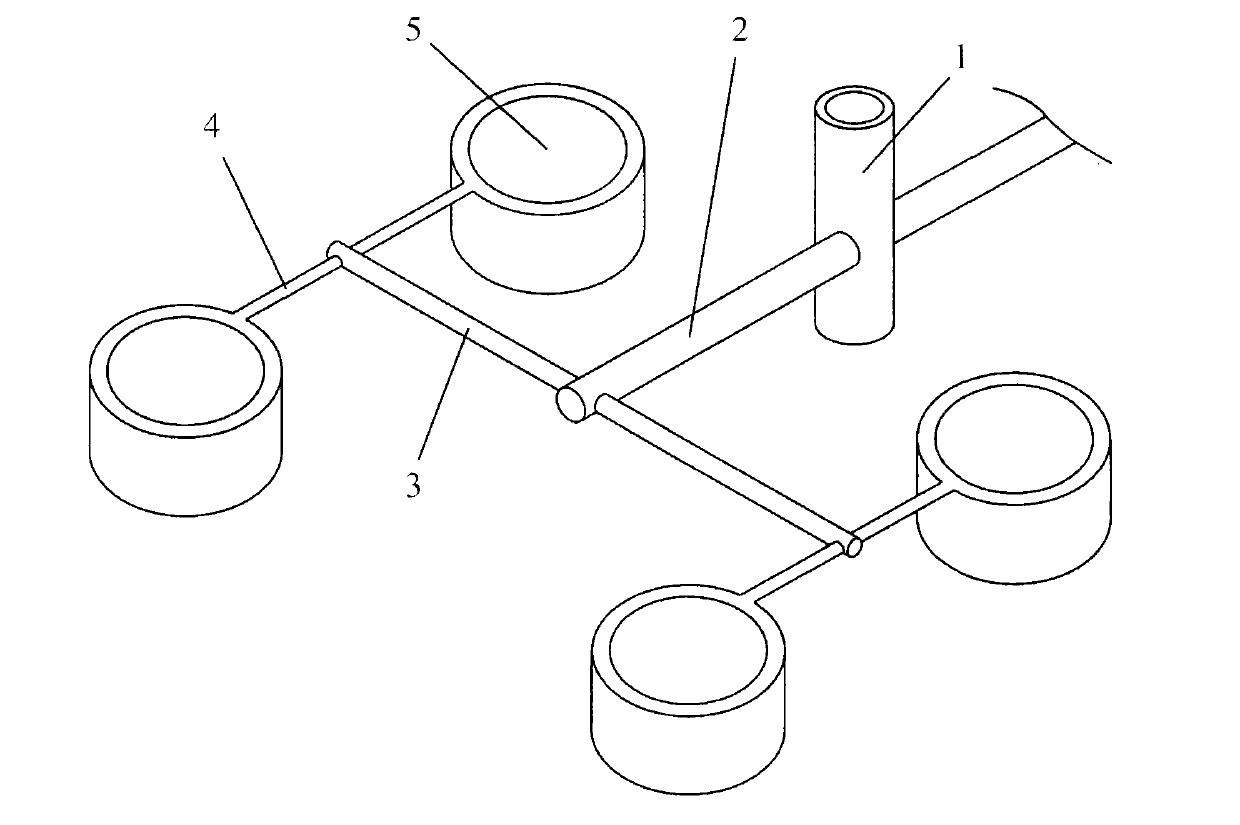

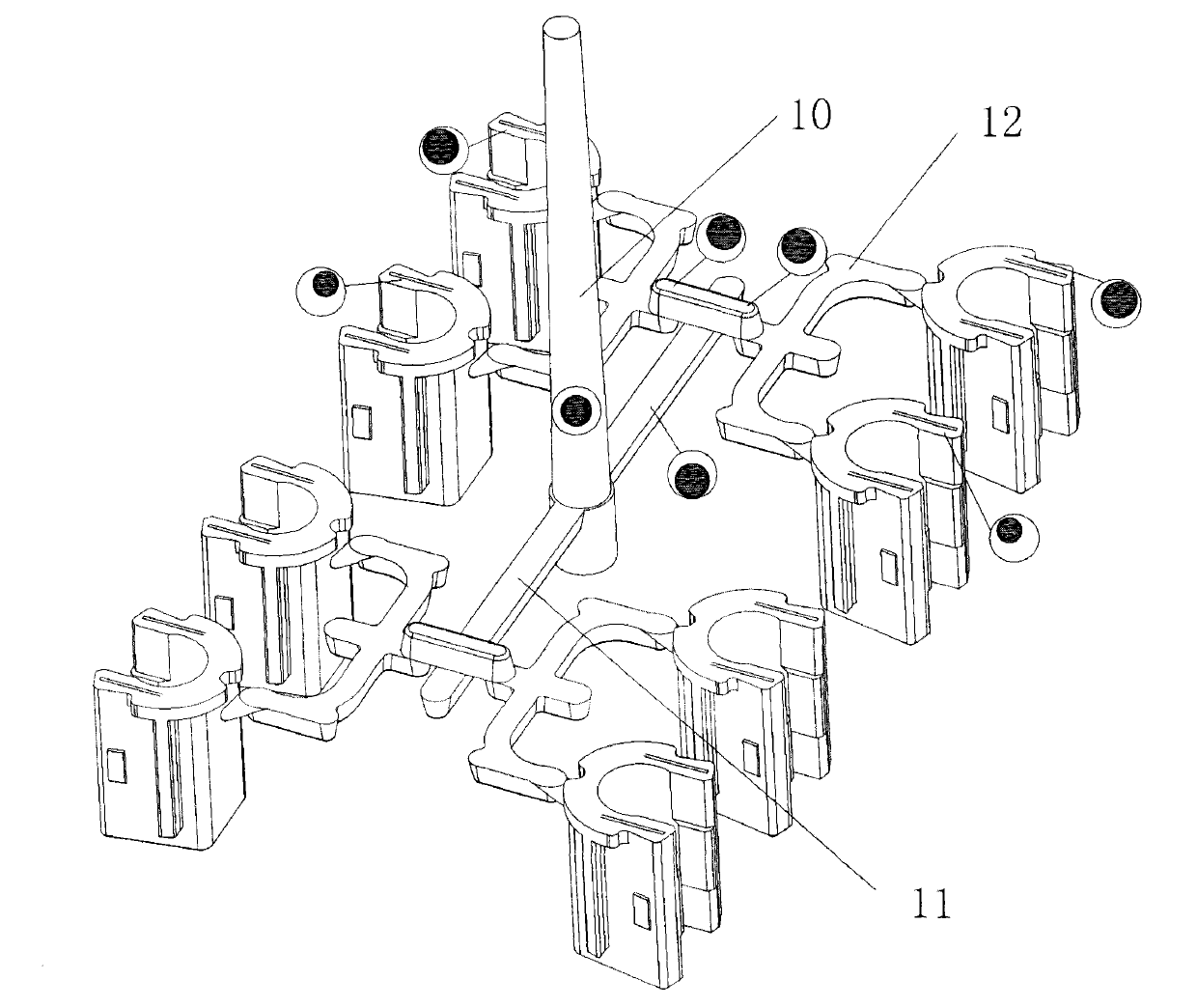

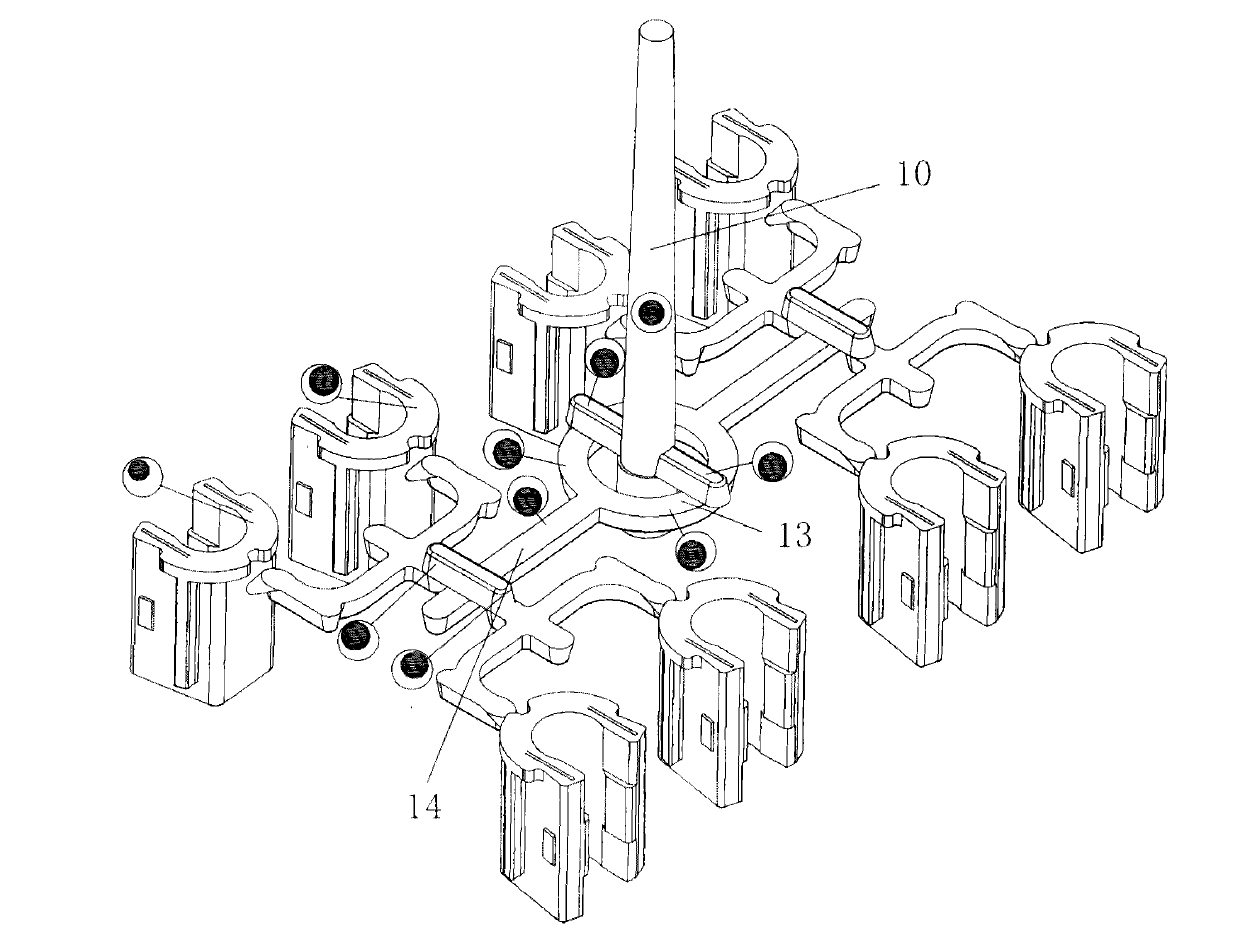

[0024] The invention provides a novel balanced cold runner structure based on the improvement made on the basis of the balanced runner structure in the existing American "Melt Flipper" technology. Such as Figure 4 As shown, the cold runner structure includes a main channel 10, the inlet 101 of the main channel 10 is a glue inlet, the outlet 102 of the main channel communicates with four straight first sub-channels 20, and The four straight first-stage flow passages are arranged in a "cross" shape, and the four straight first-stage flow passages are on the same level, and the main channel 10 is connected to the four straight first-stage flow passages 20 vertical, the shape and length of the four straight first sub-flow channels are the same, and the outlet ends 21 (i.e. ends) of the adjacent two first sub-flow channels in the four straight first sub-flow channels are connected to The two ends 31 of an arc-shaped runner 30 are overlapped, and the overlapping positions on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com