Automatic laser transverse film stabilizing device

A stabilizing device and laser technology, applied in the direction of installation, light guide, optics, etc., can solve the problems of mode symmetry, focusing performance and final processing performance changes, and achieve the effect of maintaining beam symmetry and process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

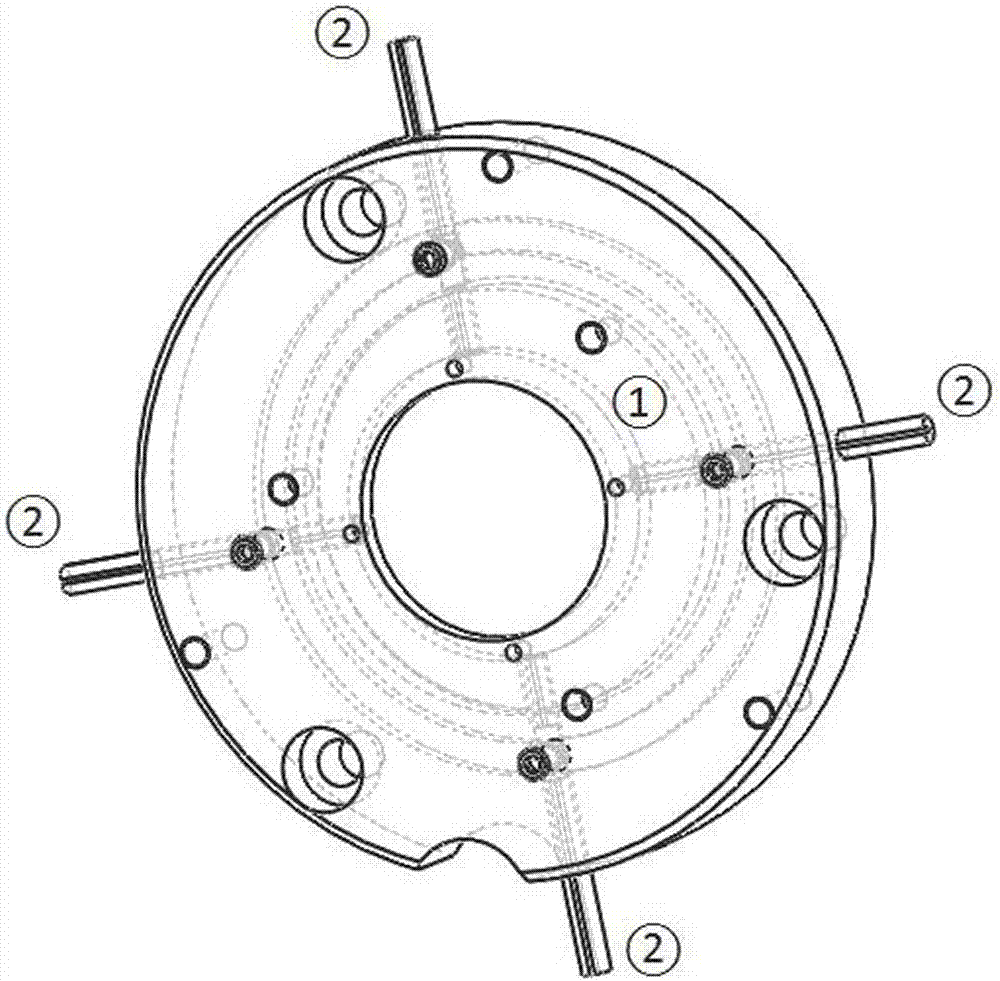

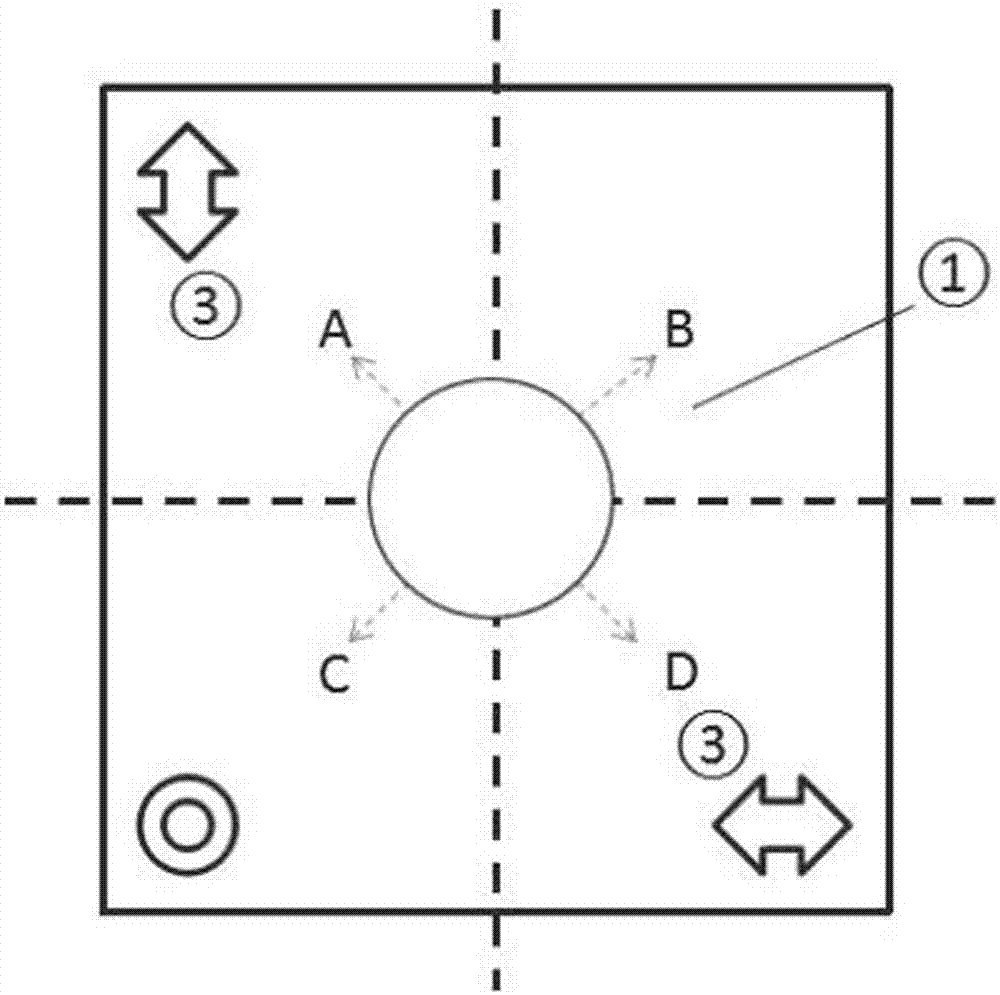

[0016] Embodiment 1, with reference to attached Figure 1-2 As shown, the present invention: an automatic laser horizontal membrane stabilizing device, comprising an output coupler 1, a temperature sensor 2 and an output coupler angle adjuster 3, and the output coupler 1 is provided with a number of evenly divided and measured output couplers 1 The temperature sensor 2 of the corresponding position temperature, the electrical connection of the temperature sensor 2 to the output coupler angle adjuster 3, the measured data is fed back to the output coupler angle adjuster 3, and the output coupling is adjusted through the output coupler angle adjuster 3 Coupler angle 1 to achieve uniform temperature on output coupler 1.

[0017] An automatic laser horizontal film stabilization device, the output coupler 1 is an output coupling lens, and a number of temperature sensors 2 are arranged on the side of the output coupling lens to evenly divide the output coupling lens and measure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com