High-precision heating furnace for mid-infrared optical fiber drawing tower

A fiber drawing tower, high-precision technology, applied in the field of infrared optical fiber preform heating furnace design, can solve the problems of unable to pull out optical fiber, large floating range of wire diameter, breakage, etc., to prevent external oxygen and air pollution, avoid analysis crystal, thick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

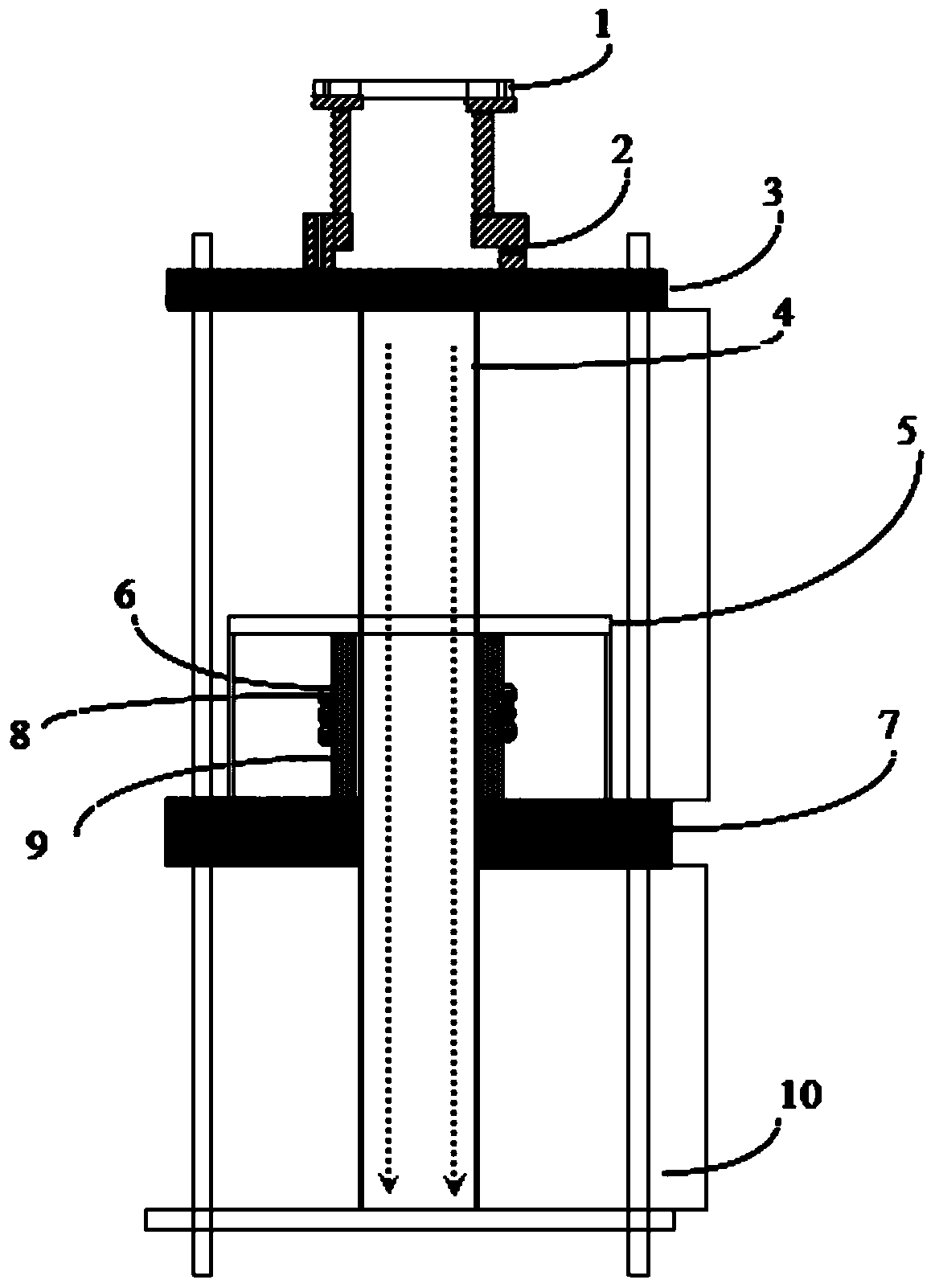

[0071] Embodiment 1 "|" shaped preform heating furnace

[0072] The whole furnace body is 50cm high and 140mm wide. It is divided into upper, middle and lower parts. The upper part is mainly the inlet device and the upper flange fixing device, the middle part is the heating part of the furnace body, and the lower part is the gas outlet device. Furnace heating part: The diameter of the heating part of the entire heating furnace is 132mm, and the height is 100-150mm. It adopts the 309 type special heating steel material in the shape of "┃┃". The size of the special heating steel material is 45-65mm in height and 8- 12mm; the size of the resistor is Φ8 (mm), and the inner diameter of the outer ceramic tube is Φ12; the quartz tube is flame-polished, the diameter is 26-38mm, the thickness of the quartz tube is 2-6mm, and the length is 45cm. The back of the special heating steel is filled with glass fiber and cotton, evenly and symmetrically filled around the quartz tube. Air inlet...

Embodiment 2

[0081] Example 2 Shaped Preform High Precision Furnace

[0082] The whole furnace body is 50cm high and 140mm wide. It is divided into upper, middle and lower parts. The upper part is mainly the inlet device and the upper flange fixing device, the middle part is the heating part of the furnace body, and the lower part is the gas outlet device. Furnace heating part: The diameter of the heating part of the entire heating furnace is 132mm, and the height is 150mm. Shaped 600 model special heating steel material, The long side is 60-80mm, the two short sides are 45-55mm, and the thickness is 8-12mm; the size of the resistance wire is Φ2-6(mm), and the inner diameter of the outer ceramic tube is Φ8; the quartz tube is flame polished, and the diameter is 26-38mm, quartz tube thickness 2-6mm, length 45cm. The back of the special heating steel is filled with glass fiber and cotton, evenly and symmetrically filled around the quartz tube.

[0083] Air inlet: Φ0.5-4 sealing ring a...

Embodiment 3

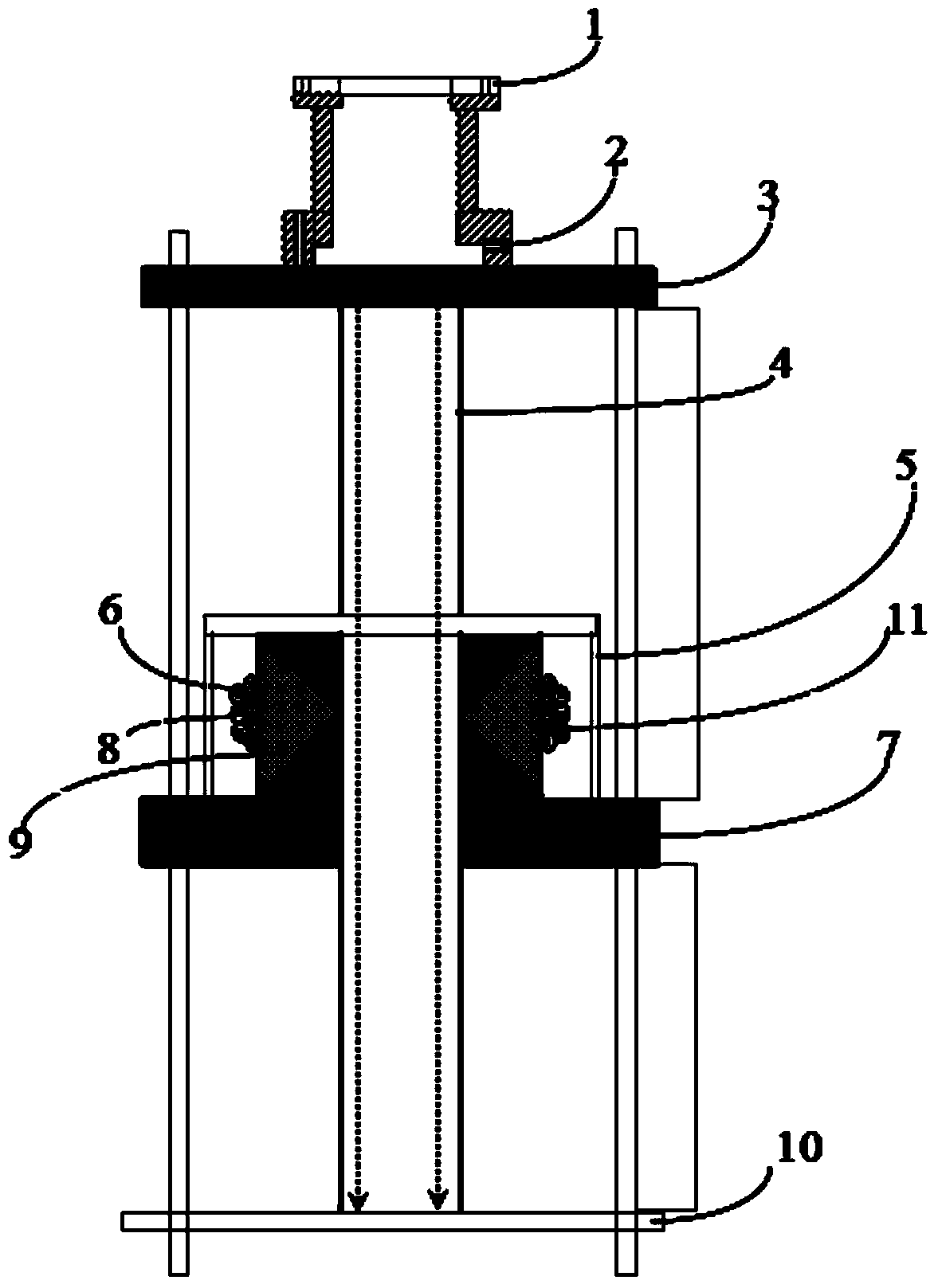

[0092] Example 3 "]" shaped preform high-precision heating furnace

[0093] The whole furnace body is 50cm high and 140mm wide. It is divided into upper, middle and lower parts. The upper part is mainly the inlet device and the upper flange fixing device, the middle part is the heating part of the furnace body, and the lower part is the gas outlet device. Furnace heating part: The diameter of the heating part of the heating furnace is 132mm, and the height is 150mm. It adopts the 630 type special heating steel material in the shape of "][", the long side of "][" is 60-80mm, the width is 20-35mm, and the thickness It is 4-8mm; the size of the resistance wire is Φ4-8 (mm), and the inner diameter of the outer ceramic tube is Φ12; the quartz tube is flame-polished, the diameter is 26-38mm, the thickness of the quartz tube is 2-6mm, and the length is 45cm. The back of the special heating steel is filled with glass fiber and cotton, evenly and symmetrically filled around the quartz ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com