Scanning head of a laser marking machine

A technology of laser marking machine and scanning head, which is applied in the field of scanning head to achieve the effect of easy maintenance and handling, preventing water leakage and overcoming the deviation of swing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

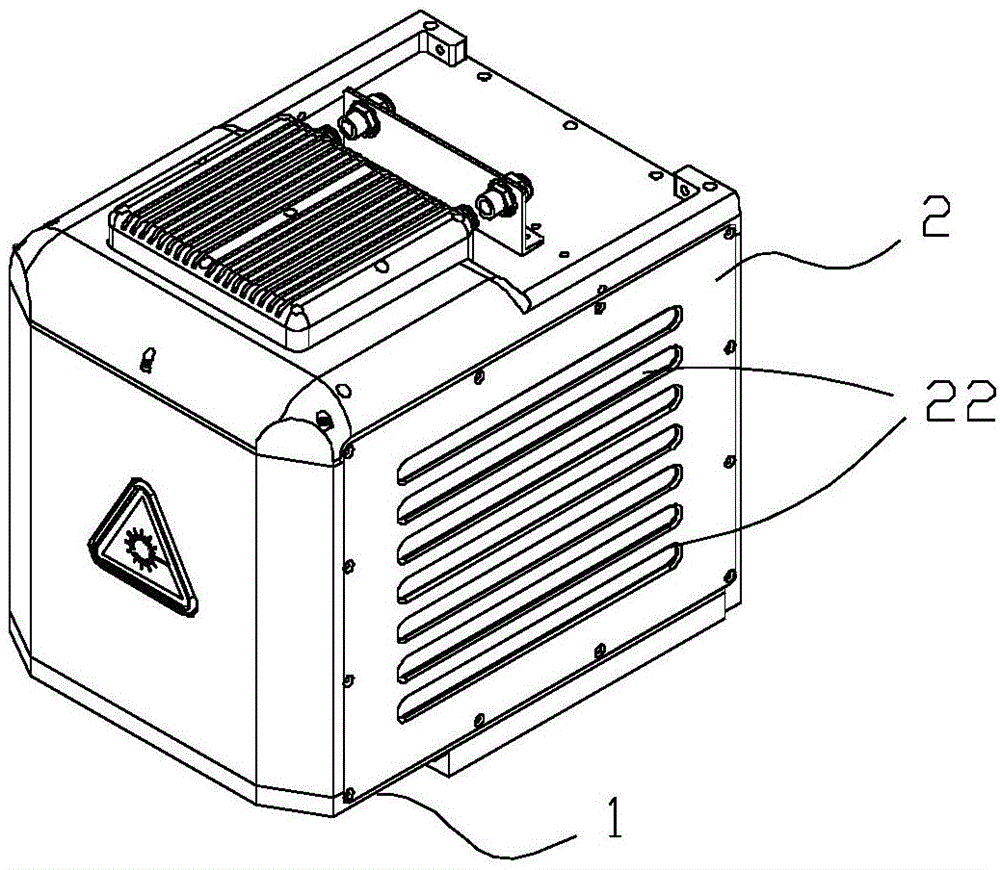

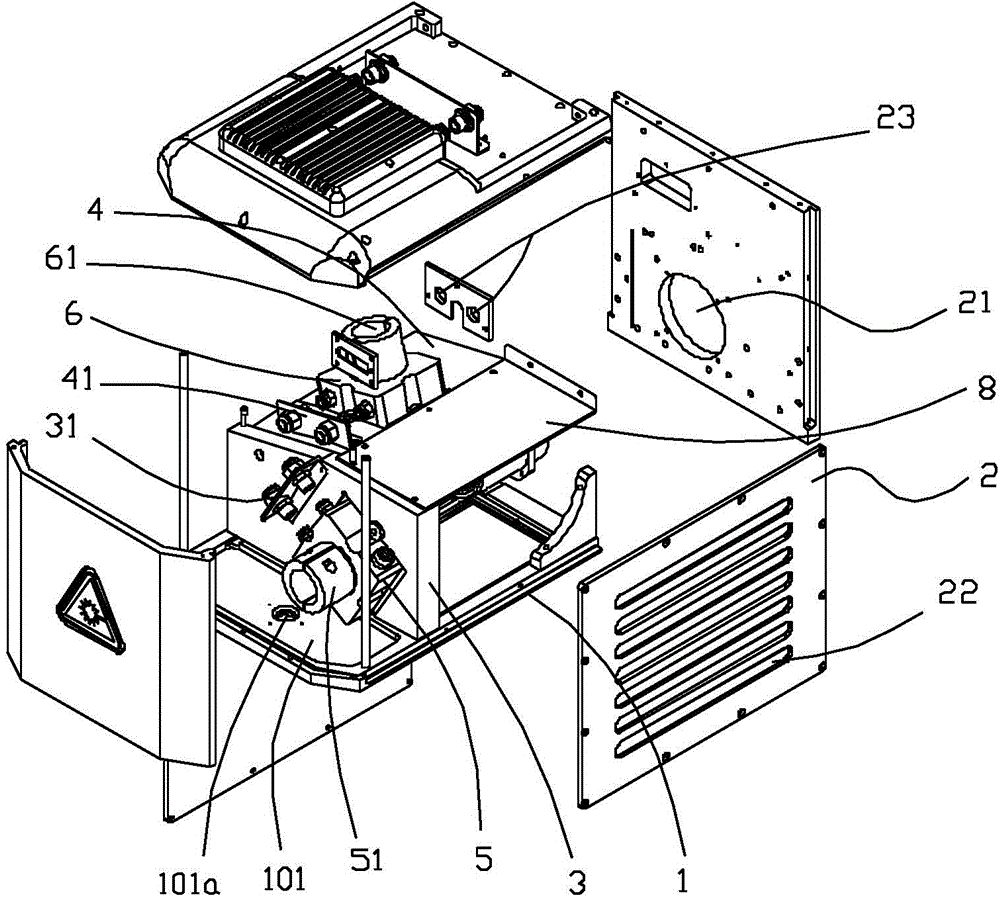

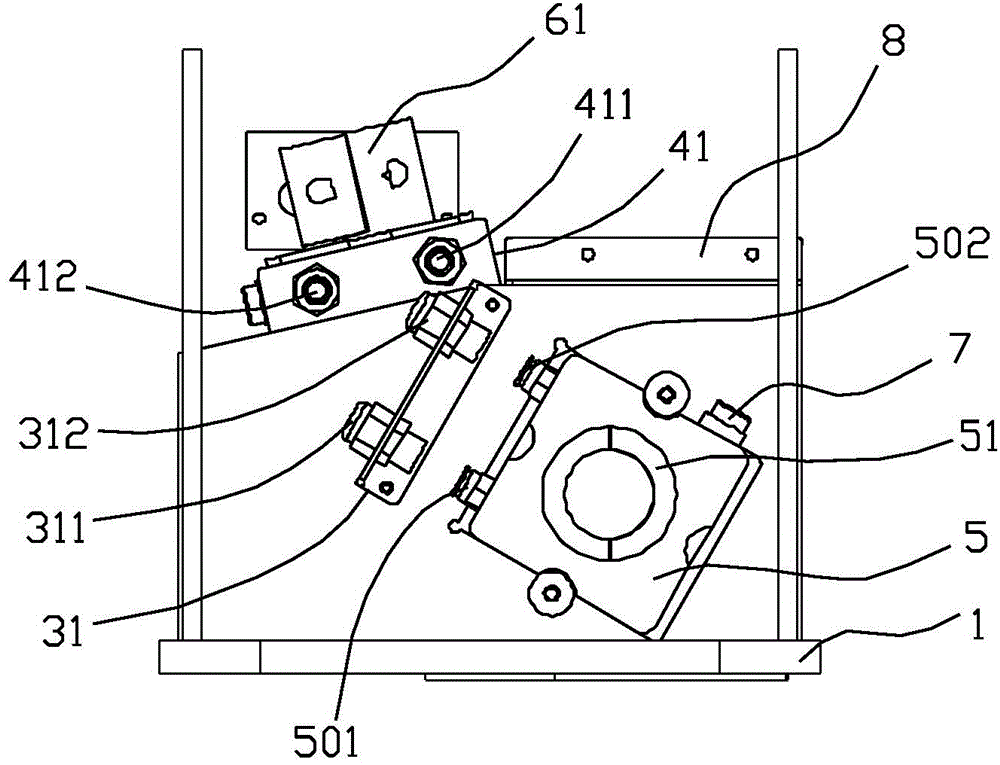

[0035] Refer to attached figure 1 to attach Figure 4 As shown, a scanning head of a laser marking machine includes a base plate 1, a housing 2 and a scanning system arranged on the base plate 1, the housing 2 is covered on the base plate 1, and the housing 2 is provided with The laser entrance 21 is corresponding to the laser exit on the bottom plate 1 . The scanning system includes a first support plate 3 and a second support plate 4, the first support plate 3 is vertically arranged on the bottom plate 1; One side of a support plate 3 is vertically connected, and the vertical connection means that the horizontal plane where the connection line between the second support plate 4 and the first support plate 3 is located is perpendicular to the first support plate 3 . The upper end of the first support plate 3 is provided with an oblique angle c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com