A kind of pallet unpacking and palletizing machine

A technology for unpacking palletizers and pallets, which is applied in the direction of object depalletizing, object stacking, transportation and packaging, etc. It can solve the problems of shelf damage, time-consuming and labor-consuming, and low automation rate, so as to improve stability, Optimize the effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

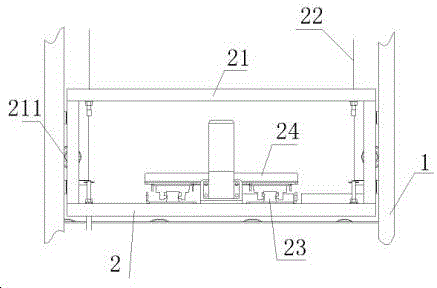

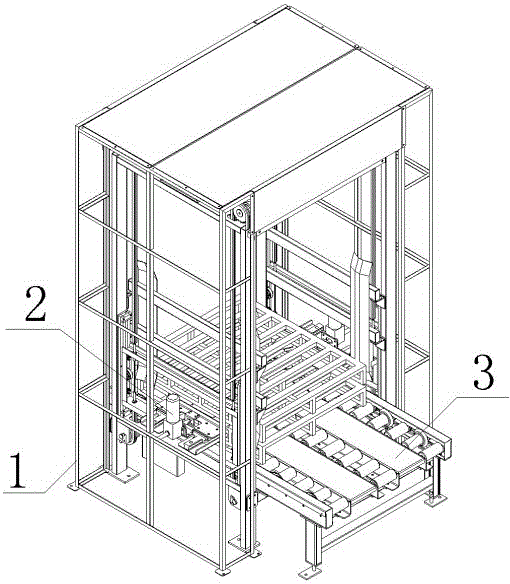

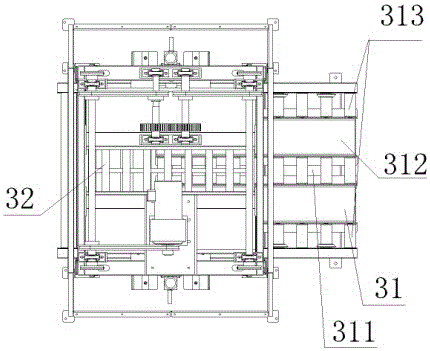

[0030] Example 1, such as figure 1 , figure 2 , image 3 and Figure 4 Shown: a kind of pallet dismantling stacker, comprises the frame 1 that stands on the ground and is located on the frame 1 and can move in the vertical direction and the horizontal direction dismantling body 2, it is characterized in that: dismantling body 2 quantity is Two, installed on the inner wall of both sides of the frame 1, the dismantling body 2 includes a frame 21, connects the frame 21 and the frame 1 and can adjust the position of the frame 21 relative to the frame 1 in the vertical direction Vertical adjustment device 22, the fork body 24 for moving goods and the horizontal adjustment device 23 that connects the fork body 24 and the frame body 21 and can adjust the relative position of the fork body 24 in the horizontal direction of the frame body 21, this pallet dismantling stacker also It includes a conveying device 3 connected to the frame 1 , whose conveying direction is perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com