Size mixing process of ceiba or cotton blended yarn

A cotton blending and sizing technology, used in textiles and papermaking, fiber processing, plant fibers, etc., can solve the problems of high hairiness and poor wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

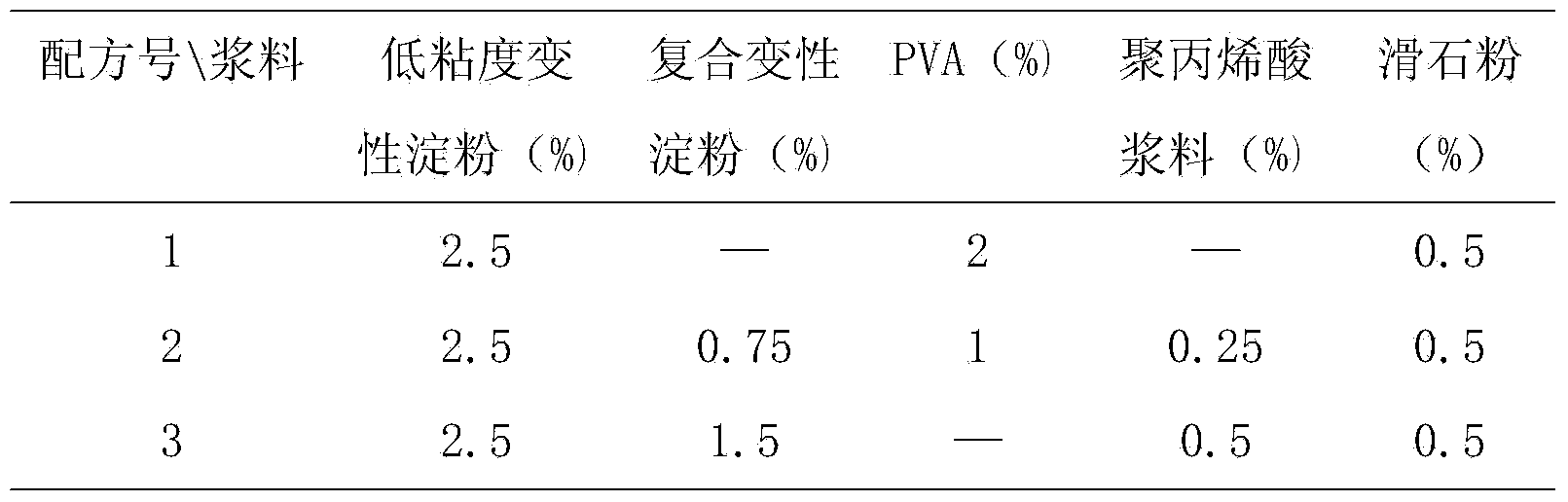

[0077] The sizing process of the kapok or cotton blended yarn is as follows: sizing is carried out according to the following steps: 20% water is added in the sizing tank, and high and low speed agitators are started; then 0.5% talcum powder, Put 2.5% low-viscosity modified starch, 1.5% compound modified starch, and 0.5% polyacrylic acid into the pressure mixing tank: add 75% of the remaining water to correct the mixing volume, close the top cover of the pressure mixing tank; open The steam valve is heated, and when the temperature reaches 115°C, the steam inlet valve is automatically closed, and the pulp is stuffed, that is to say; among them:

[0078] Mixing temperature: When the temperature in the pressure mixing tank rises to 90°C, all the cold air in the barrel is exhausted, the high pressure is converted, and the exhaust valve is automatically closed. When the temperature in the barrel rises to 115°C, the intake valve is automatically closed. The pulping is completed;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com