Anti-collision self-resetting boundary frame for overspan highway railway bridge

A road and railway bridge, self-resetting technology, applied to roads, roads, restricted traffic and other directions, can solve problems such as potential safety hazards, and achieve the effects of strong applicability, stable protection, and prolonged action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

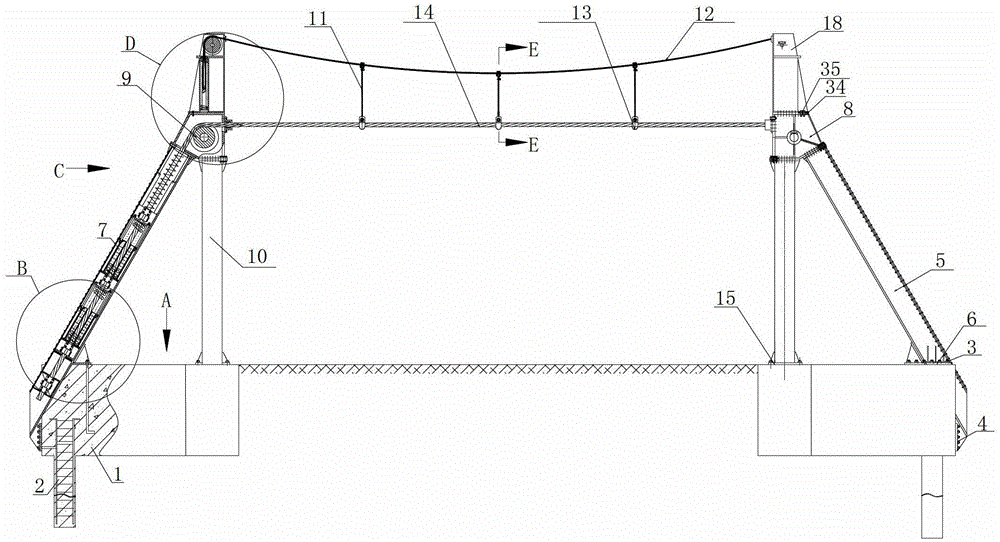

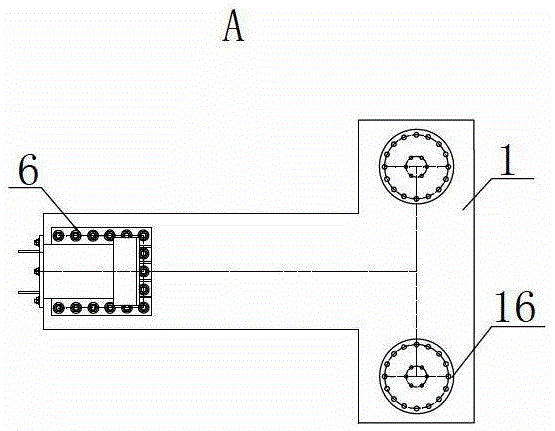

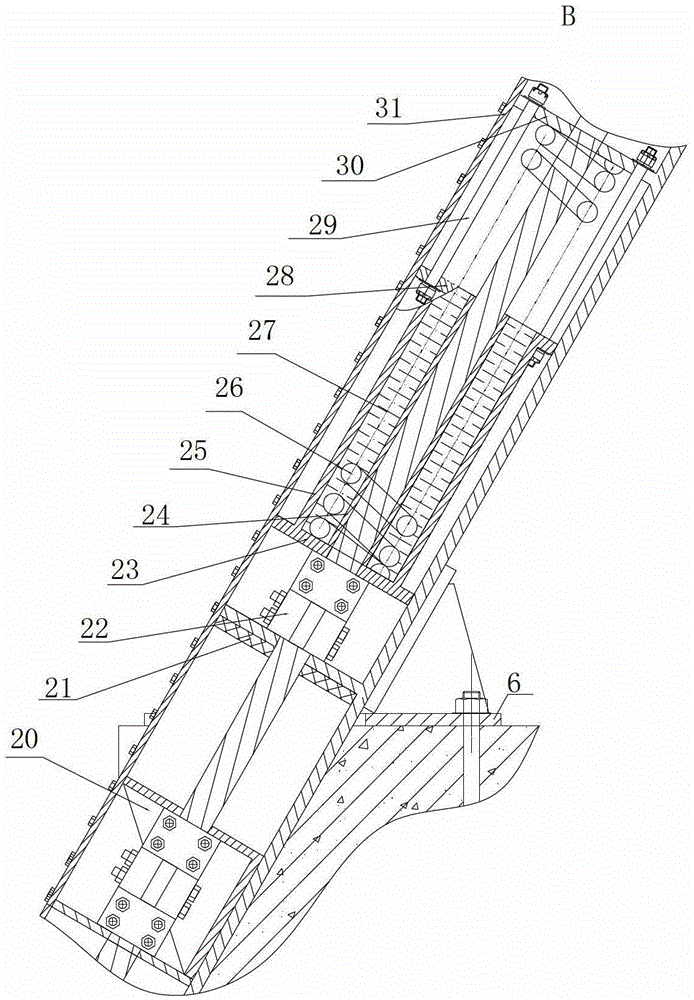

[0031] Such as figure 1 As shown, the anti-collision self-resetting limit frame of the over-span highway railway bridge includes a U-shaped beam 5, an A-shaped mast 10, a support 18, an adjustment seat 8, an intercepting steel cable 14 and a cable-stayed positioning cable 12, and the U-shaped beam 5 and the bottom end of the A-shaped mast frame 10 are fixed on the concrete foundation 1. The A-shaped masts 10 are respectively located on both sides of the lower part of the upper-span highway railway bridge, and are parallel to the road. The outer sides of the A-shaped masts 10 are respectively provided with U-shaped beams 5, and the U-shaped beams 5 on both sides of the road are arranged symmetrically. The mast 10 is vertically arranged, the U-shaped beam 5 is arranged obliquely, and the included angle between the U-shaped beam 5 and the vertical direction can be any angle of 30°-90°. The top of the A-shaped mast 10 is provided with a support 18 , and the U-shaped beam 5 , the ...

Embodiment 2

[0041] In this embodiment, the angle between the U-shaped beam and the vertical direction is 0°, that is, the U-shaped beam is in the vertical direction. Now the U-shaped beam is positioned in the pipe of one of the lower brackets 19, and the top of the bracket 18 is provided with a horizontal jack 41, by which the horizontal jack 41 can balance and intercept the power in the steel cable on the one hand, and also can be used to fix the whole Boundary frame.

[0042] When the angle between the U-shaped beam and the vertical direction is small, a horizontal jack bar can also be fixedly arranged on the top of the support.

[0043] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com