A pre-embedded slab for steel pipe column pedestal by hole pile method and its construction method

A technology of pre-embedded slabs and steel pipe columns, which is applied in infrastructure engineering, construction, etc., can solve the problems of complex installation of steel pipe positioners and difficult construction, and achieve the effects of reducing construction difficulties, improving installation accuracy, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

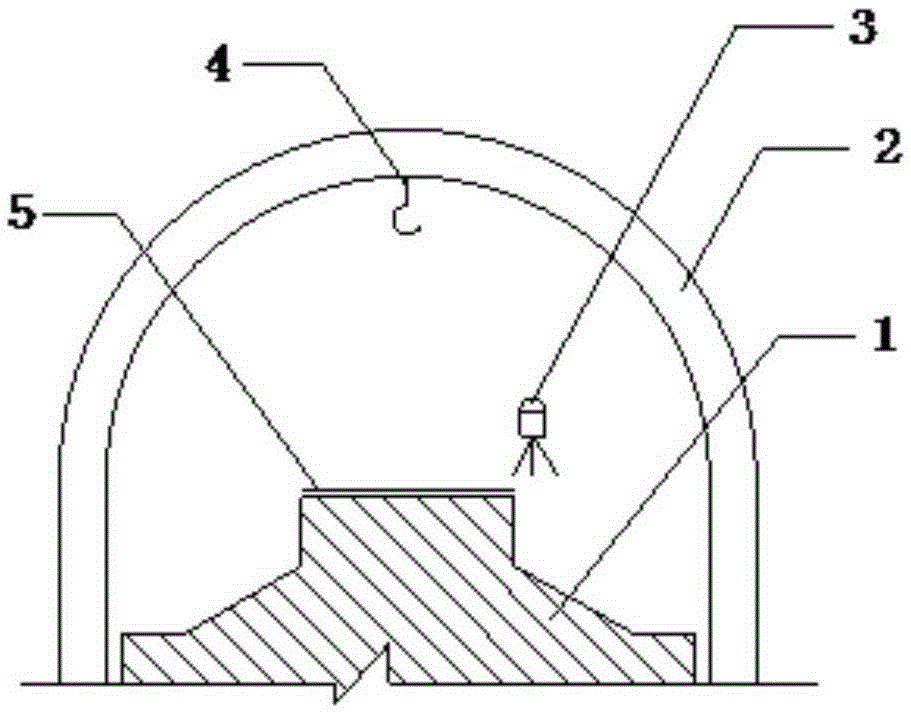

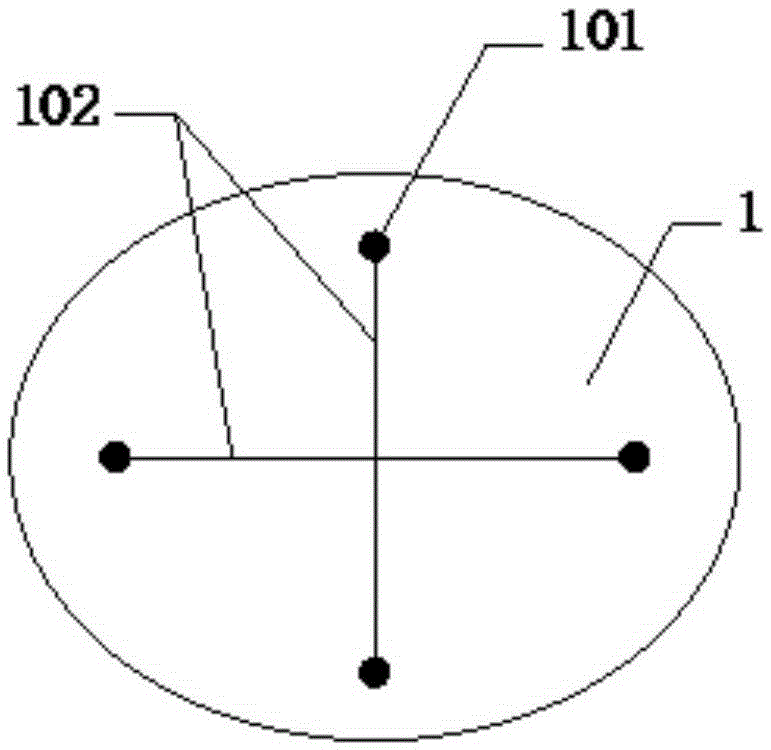

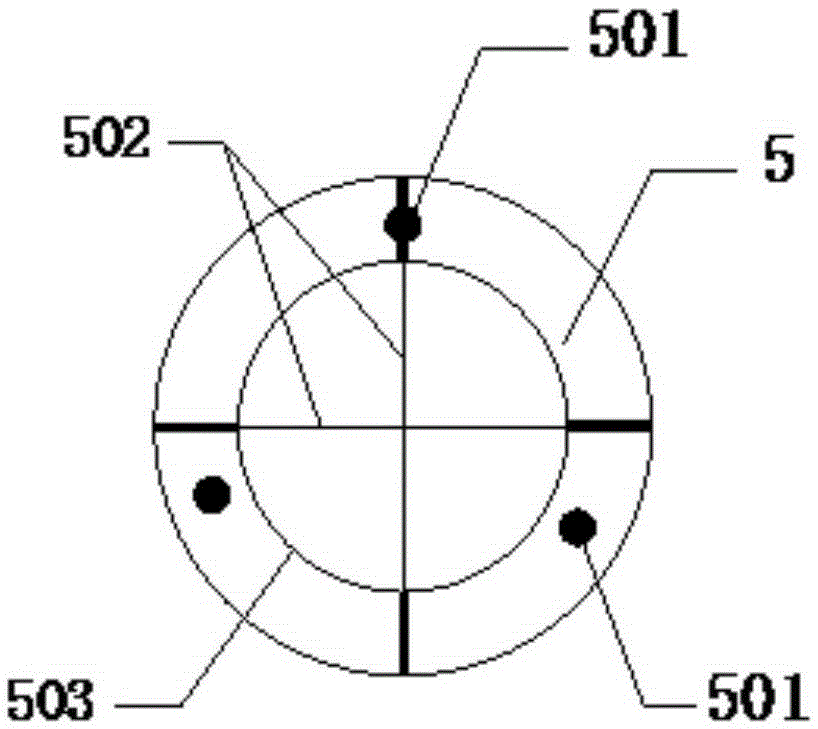

[0033] A pre-embedded slab pedestal for a steel pipe column with hole pile method, including a bottom longitudinal beam 1, and a plurality of positioning rods vertically arranged on the bottom longitudinal beam (the location of the positioning rods is set between the embedded slab and the bottom longitudinal beam); The positioning rod is welded on the main rib of the bottom longitudinal beam; the embedded plate 5 is horizontally arranged on the positioning rod; preferably, the embedded plate is provided with a positioning hole 501, and the positioning rod passes through the positioning hole, and the positioning rod is a screw , adjusting the horizontal height of the embedded plate through nuts; preferably, the embedded plate is a circular steel plate. On the pre-embedded board, draw a circle with the center of the pre-embedded board as the center and the sum of the radius of the steel pipe column + the design reserved value as the radius (that is, the positioning circle 503), a...

Embodiment 2

[0037] Steel pipe column embedded plate installation

[0038] (1) Measurement positioning

[0039] The measurement team will place the central point of the steel pipe column of each axis at the initial support vault; calculate the elevation value of the bottom plate of the steel pipe column of each axis according to the drawings, and make records and delivery methods; the full-time construction technician will guide the workers on site to set out the steel pipe column The center point of the bottom plate.

[0040] (2) Steel pipe column embedded plate installation

[0041]Position the steel plate at the base of the column, divide the four equal lines of the steel plate at the base of the column, first arbitrarily determine a chord line, use the chord line as the perpendicular line to determine the axis A, and use the axis A as the perpendicular line to determine the axis B, and the ink line can be seen on the steel plate (When the pre-embedded slab is circular, it is the quar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com