Offshore wind turbine large-diameter single-pile foundation with ice-resistant structures

A technology for offshore wind turbines and single-pile foundations, which can be used in infrastructure engineering, protection devices, buildings, etc., and can solve problems such as large engineering volumes, and achieve the effect of reducing the effect and facilitating disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

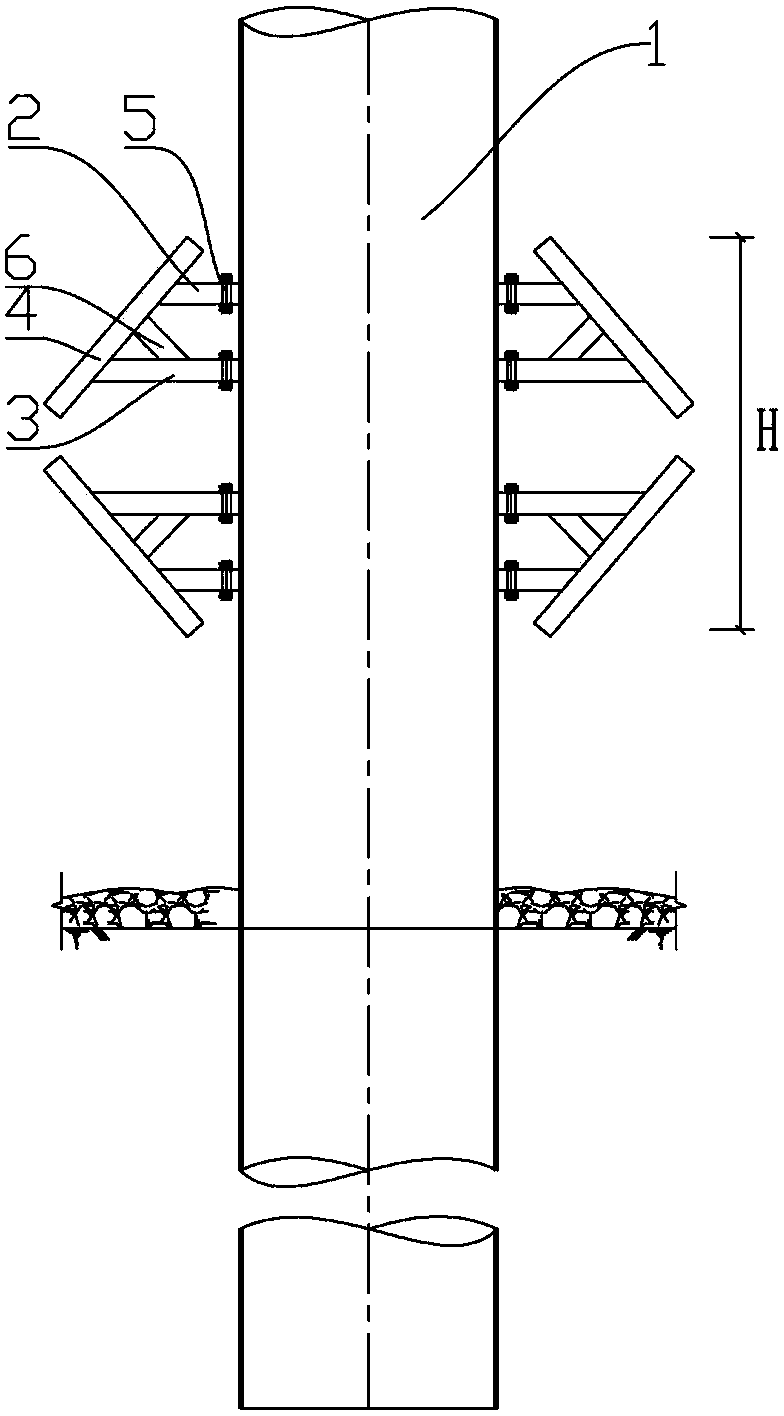

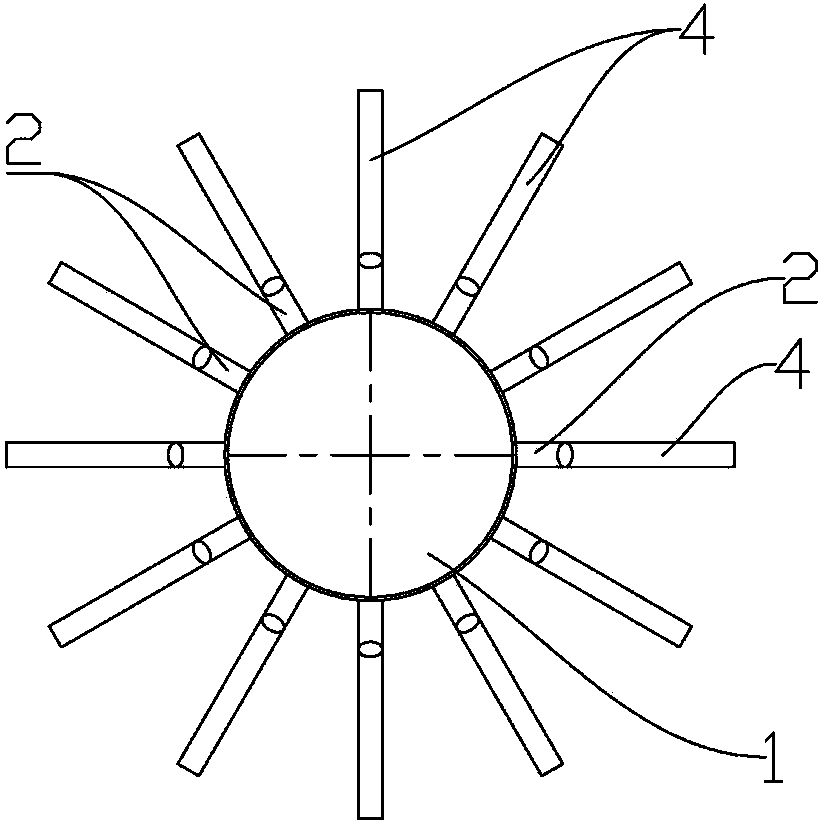

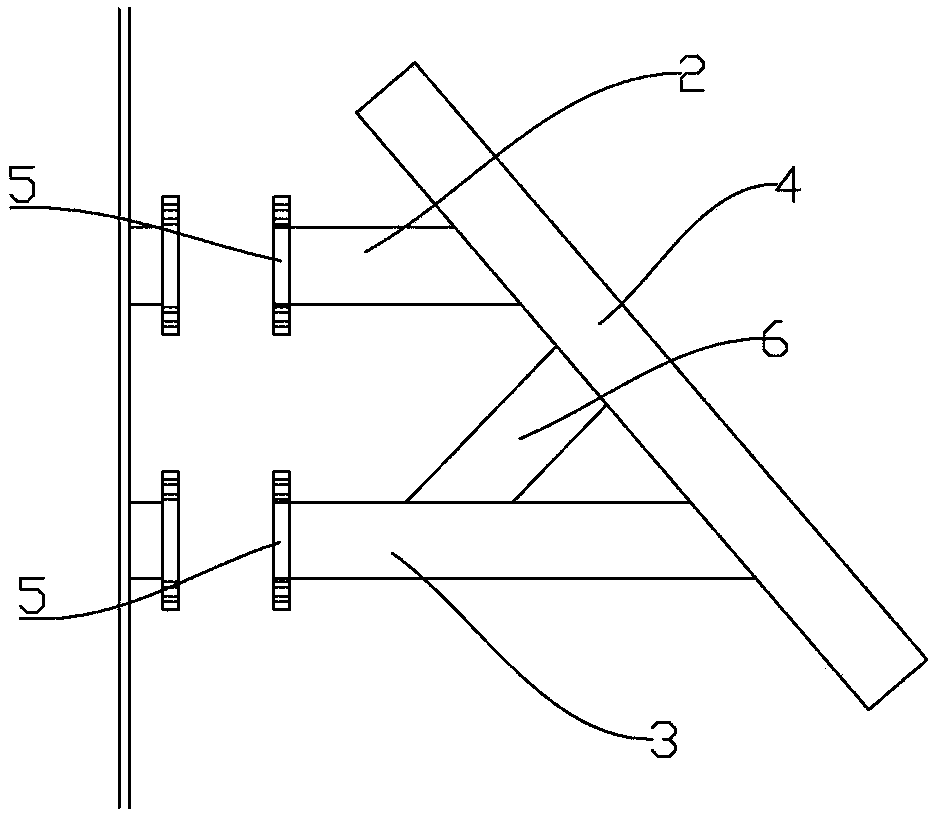

[0024] Embodiment 1: as Figure 1~Figure 4 As shown, this embodiment includes a steel pipe type large-diameter single pile 1 and an anti-icing structure arranged outside it. The anti-icing structure needs to cover the elevation range (H) of sea ice action. The anti-icing structure is arranged in two circles, upper and lower. A pair is installed in mirror image at each position relative to the horizontal plane. In this example, the anti-ice structure includes short horizontal support tube 2, long horizontal support tube 3, outer inclined tube 4 and flange plate 5, the short horizontal support tube 2 and the long horizontal support tube 3 are arranged in parallel up and down, and the inner ends of the two horizontal support tubes Both are formed with flanges 5, and the outer ends of the two horizontal support pipes are welded together to fix the outer inclined pipe 4, and the long horizontal support pipe 3 and the outer inclined pipe 4 are welded with an inclined support pipe 6....

Embodiment 2

[0026] Embodiment 2: as Figure 5~Figure 8 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, except that the anti-ice structure in this example consists of a short horizontal support tube 2, a long horizontal support tube 3, a horizontal connecting rod 7, a support tube 8, and an outer inclined tube. 4 and a flange 5, in which two outer inclined tubes 4 and a horizontal connecting rod 7 are welded into a triangular inclined tube assembly; the short horizontal support tube 2 and the long horizontal support tube 3 are arranged in parallel up and down, and the short horizontal support tube 2 and the Diagonal bracing pipes 6 are welded between the long horizontal bracing pipes 3 . Both the short horizontal support tube 2 and the inner end of the long horizontal support tube 3 are provided with a flange 5, and the outer end of the long horizontal support tube 3 is connected to the vicinity of the corner ends of the two outer inclined tubes 4 ...

Embodiment 3

[0027] Embodiment 3: as Figure 9 As shown, the structure of this embodiment is basically the same as that of Embodiment 2, the only difference is that in this embodiment, a steel plate 9 is provided in the area between the two outer inclined pipes 4 of the triangular inclined pipe assembly, which helps the sea ice along the outer side of the anti-icing structure. Climb breaks in sloped areas. In this example, the horizontal connecting rods 7 play the role of the inner ribs, assisting the supporting steel plate 8, and the number of the horizontal connecting rods 7 is set as required.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap