Gas extraction hole drilling hole sealing technology in manner of two-end self-blocking and under pressure

A technology of sealing holes under pressure and gas drainage, which is applied in earthwork drilling, sealing/isolation, wellbore/well components, etc., which can solve the problems of poor sealing effect, inability to carry pressure, complicated process, etc., and achieve sealing Improved pore efficiency, low cost, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

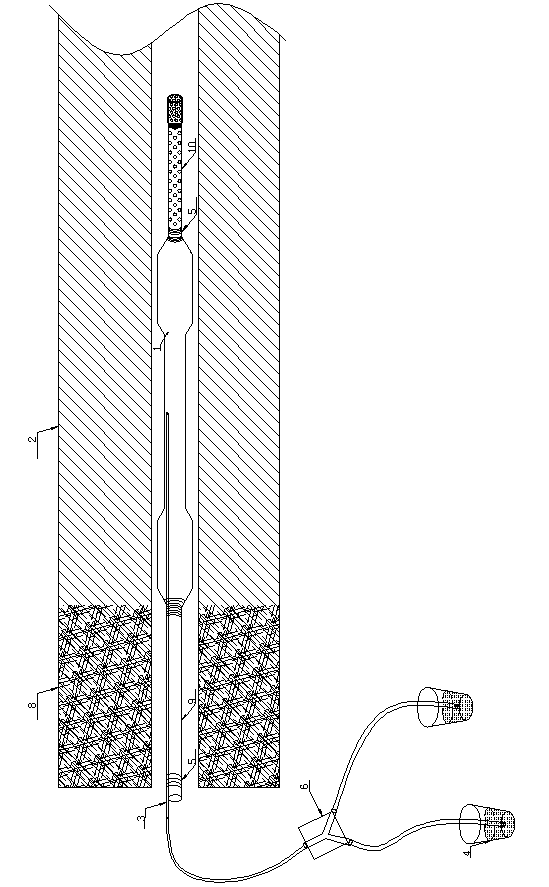

[0017] Embodiment 1: as figure 1 As shown, a kind of self-plugging and pressure-sealing process at both ends of a gas drainage borehole uses a hole-sealing device inside the borehole, adopts self-plugging at both ends of the pressure-sealing bag grouting and sealing method, and uses a sealing material Conduct drainage drilling and sealing. The length of the sealing section of bedding drilling is 5-8m.

[0018] The drilling inner hole sealing device is mainly composed of self-blocking pressure sealing bag 1 with both ends, sealing pipe for coal mine, grouting pipe 3, flower pipe and steel window screen.

[0019] Drill holes for gas drainage during construction; wrap the head of the first flower tube 10 with a steel window screen and tie it firmly with cable ties 5; Top; Insert the grouting pipe 3 to the middle of the sealing section of the self-plugging pressure-sealing pouch 1 at both ends; use cable ties, 12# iron wire or wide transparent tape to seal the hole The pouch 1,...

Embodiment 2

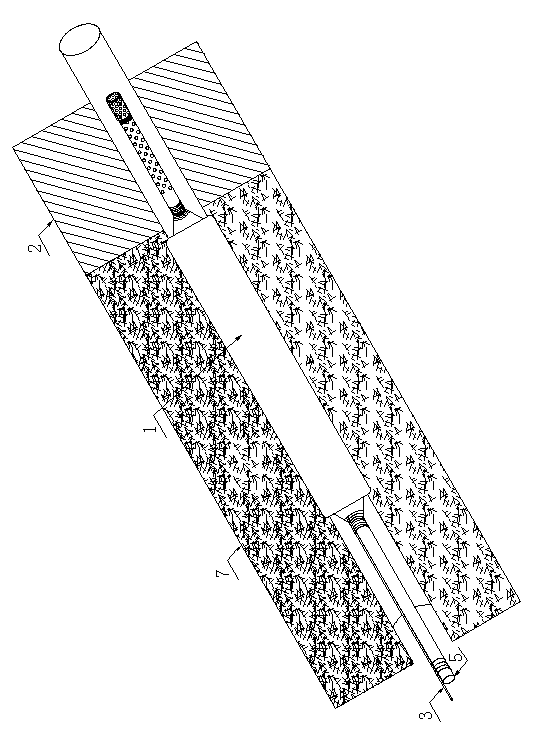

[0033] Embodiment 2: as figure 2 As shown, a kind of self-plugging and pressure-sealing process at both ends of a gas drainage borehole uses a hole-sealing device inside the borehole, adopts self-plugging at both ends of the pressure-sealing bag grouting and sealing method, and uses a sealing material Conduct drainage drilling and sealing. The length of the sealing section of drilling through layers shall not be less than 5m.

[0034] The hole sealing device and the hole sealing material are the same as those in Example 1.

[0035] Layer-through drilling and sealing process: a. Layer-through drilling and sealing adopts self-plugging at both ends, pressure sealing, bag-type grouting and sealing, and new sealing materials.

[0036] b. After the drilling construction is completed, confirm the drilling depth on the rock layer 7 and the length of the coal hole section on the coal seam 2, sweep the holes with compressed air, and seal the holes and pump them in time.

[0037] c. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com