Exhaust gas ejection muffler

A technology of muffler and exhaust gas, applied in muffler device, exhaust device, machine/engine, etc., can solve the problems of filter element blockage, reduced filter element service life, engine power loss and fuel consumption increase, etc., to achieve the frequency of filter element replacement The effect of reducing, extending service life, saving man-hours and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

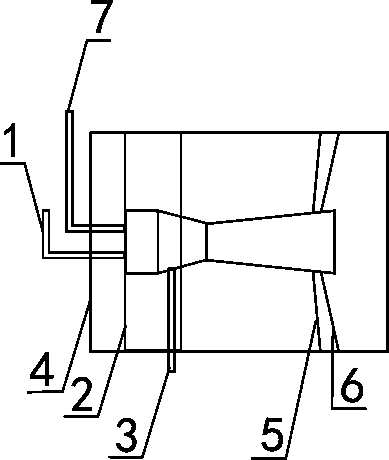

[0013] Such as figure 1 As shown, the left side of the exhaust gas ejection muffler shell 4 is provided with an exhaust gas ejection port 1, an air inlet 7, and the lower part is provided with an exhaust port 3; the interior of the shell 4 is provided with a Venturi tube; One side inlet of the venturi tube is connected; the air inlet 7 is connected with the rear part of the Venturi tube; the exhaust port 3 is connected with the lower outlet of the Venturi tube; the front part of the Venturi tube is supported by the bracket 2, and the rear part of the Venturi tube is Supports 5 and 6 are supported.

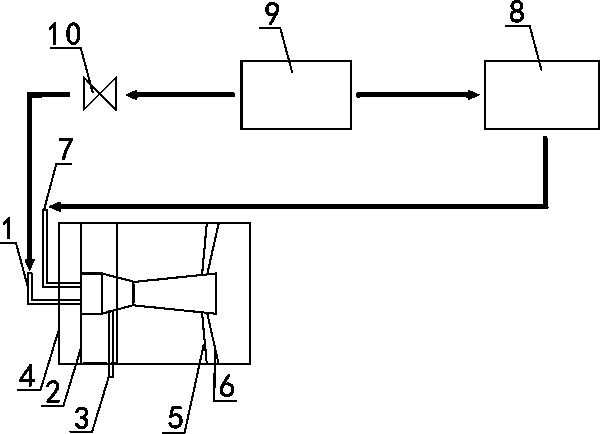

[0014] Such as figure 2 As shown, 1 is the exhaust gas injection port, 2 is the bracket, 3 is the exhaust port, 4 is the shell, 5 is the bracket, 6 is the bracket, and 7 is the air inlet; the air inlet 7 and the exhaust pipe of the engine 8 Connection; the filter 9 is connected to the exhaust gas injection port through the one-way valve 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com