Iron wire glass candle holder and manufacturing process thereof

A production process and iron wire technology, applied in the field of iron wire glass candlesticks and its production process, can solve the problems of single style, single color, fragile candlesticks, etc., achieve good light transmission, stable quality control, and increase light transmission performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

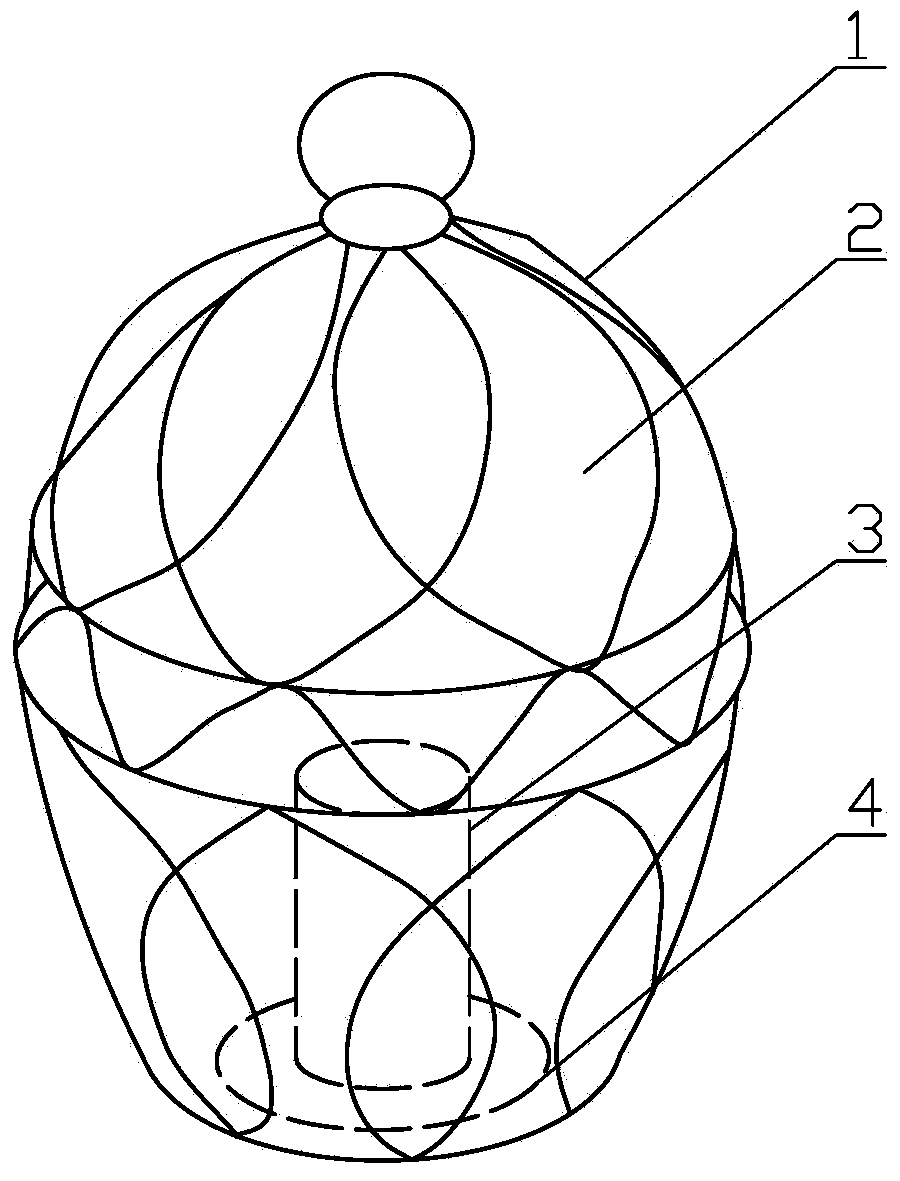

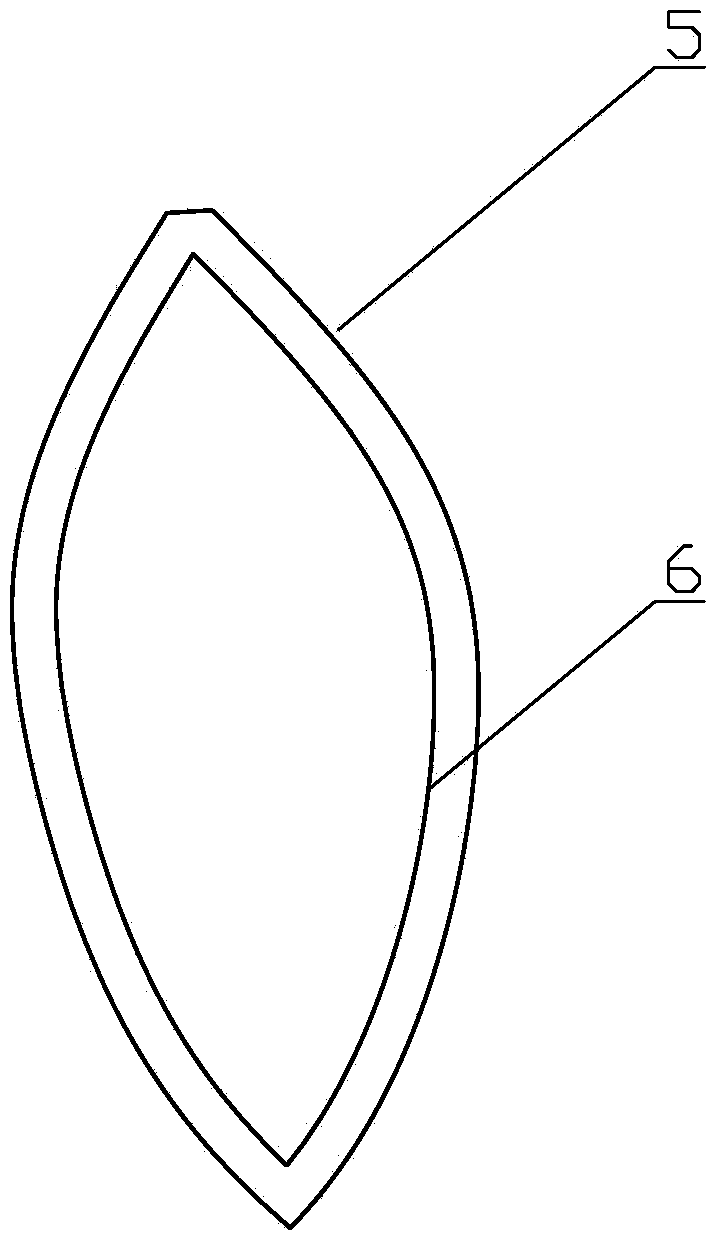

[0027] like figure 1 , figure 2 As shown: the iron frame 1 is provided with a transparent glass inner cavity 2, and the iron frame 1 is composed of iron wires 5, and the glass inner cavity is located in the gap between adjacent iron wires 5, and there is an outwardly protruding protrusion 6 .

[0028] The manufacturing steps of this embodiment are as follows:

[0029] 1) Make wire frame;

[0030] 2) wire frame preheating;

[0031] 3) Bubbles are blown inside the wire frame to form a glass cavity, and the glass cavity protrudes from the gap in the wire frame to form a bulge when blowing bubbles;

[0032] 4) Iron wire frame annealing;

[0033] 5) Iron wire frame anti-rust surge;

[0034] 6) Translucent treatment of the inner cavity of the glass, soaking the entire candlestick in the translucent treatment solution, the translucent treatment solution is composed of 1% hydrofluoric acid, 2% acetone, and 97% water;

[0035] 7) Rinse with water and dry.

Embodiment 2

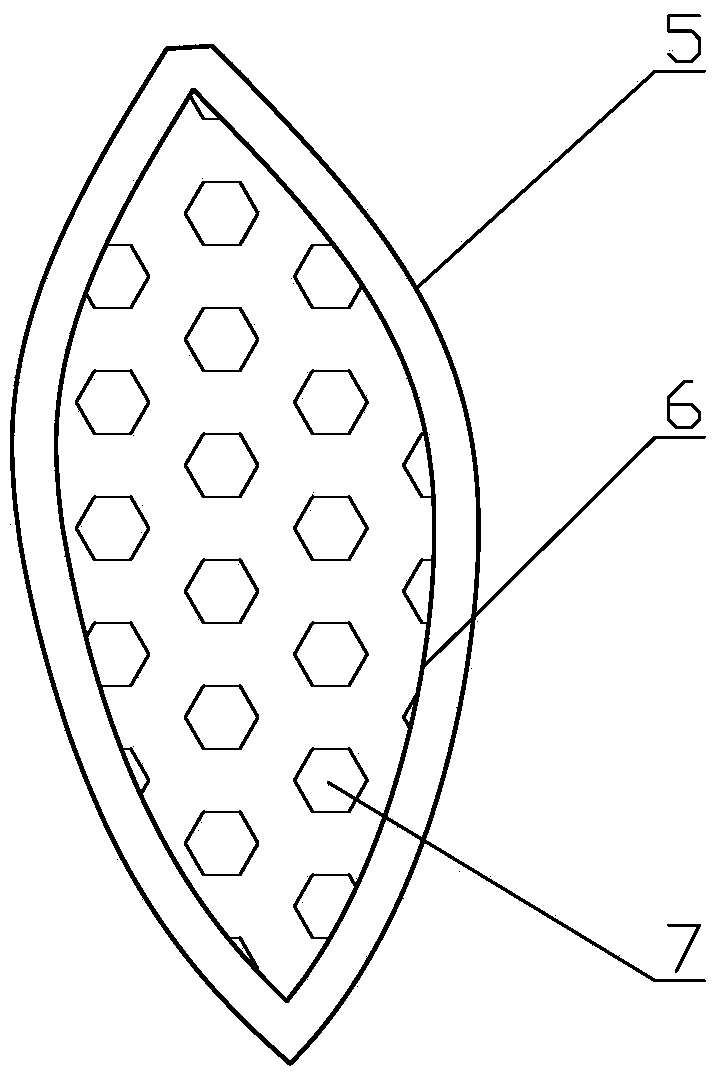

[0037] like figure 1 , image 3 As shown: the iron frame 1 is provided with a glass inner cavity 2, and there are multiple air bubbles in the outer wall of the glass inner cavity. The iron art frame 1 is composed of iron wires 5, and the glass inner cavity is located in the gap between adjacent iron wires 5 Protrusions 6 protruding outward are provided.

[0038] The manufacturing steps of this embodiment are as follows:

[0039] 1) Make wire frame;

[0040] 2) wire frame preheating;

[0041] 3) Blow bubbles inside the iron wire frame to form a glass inner cavity. When blowing bubbles, the glass inner cavity protrudes from the gap in the iron wire frame to form a bulge. When blowing bubbles, spray alkali surface to the outer wall of the glass inner cavity, Bubbles form in the outer wall of the glass lumen.

[0042] 4) Iron wire frame annealing;

[0043] 5) Iron wire frame anti-rust surge;

[0044] 6) Translucent treatment of the inner cavity of the glass, soaking the ent...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap