Vertical-installation multifunctional air valve device

A vertically installed, multi-functional technology, applied in the direction of airflow control components, etc., can solve the problem of entering the station, sometimes entering the tunnel from the station, and achieve the effect of reducing energy consumption and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings.

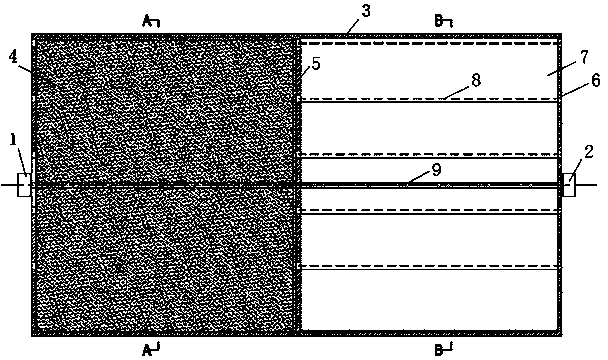

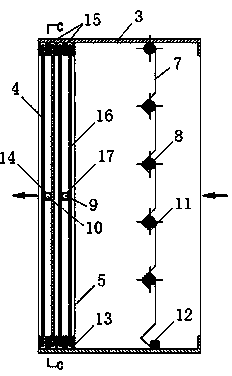

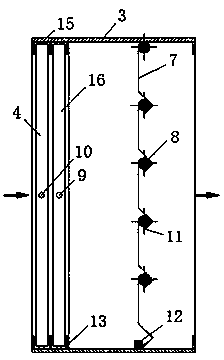

[0026] figure 1 It is a structural schematic diagram of the vertically installed multifunctional damper device of the present invention; figure 2 and image 3 is the internal structure diagram of the damper device; Figure 4 It is the internal structure diagram of the slideway structure. Such as Figure 1 to Figure 4 As shown, the vertically installed multifunctional air valve device of the present invention includes a valve body frame 3, a partition plate 5, a self-suspended movable blade 7, a sliding valve plate and a transmission mechanism. The valve body frame 3 is divided into two channels on the left and right by the central partition plate 5, and each channel is provided with a set of self-suspended movable vanes 7 that can only be opened in one direction, and the opening direction of the self-suspended movable vanes in the two chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com