High reproducibility optical element surface shape detection support device

An optical element and support device technology, which is applied in the field of high-reproducibility optical element surface shape detection support devices, can solve the problems that the optical element detection state is different from the final use state, cannot meet the requirements of surface shape convergence, etc., and achieves deformation Stable state, high repeatability and high surface reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

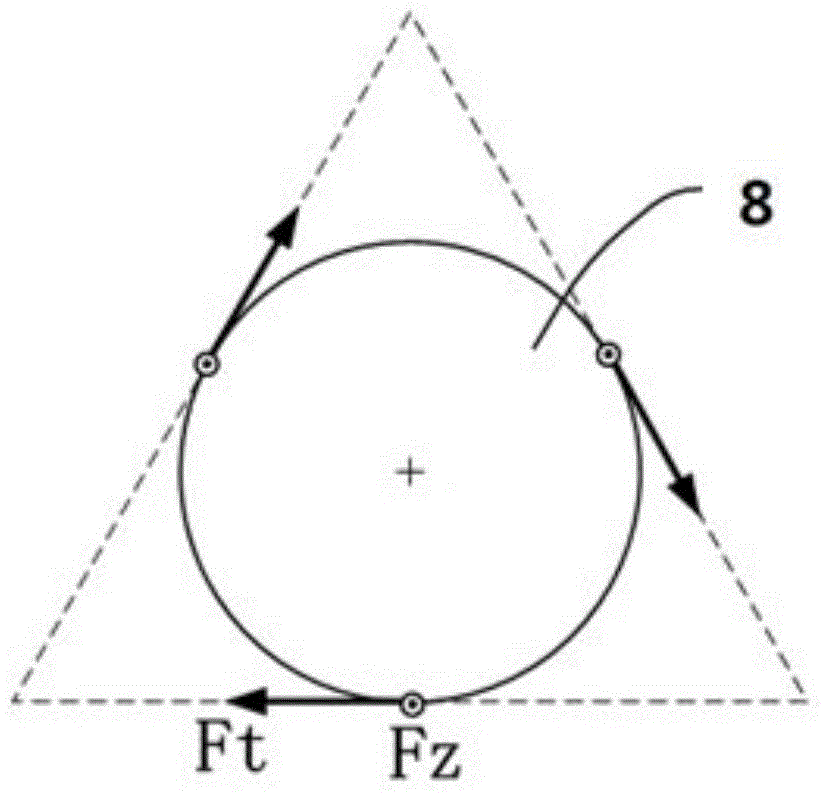

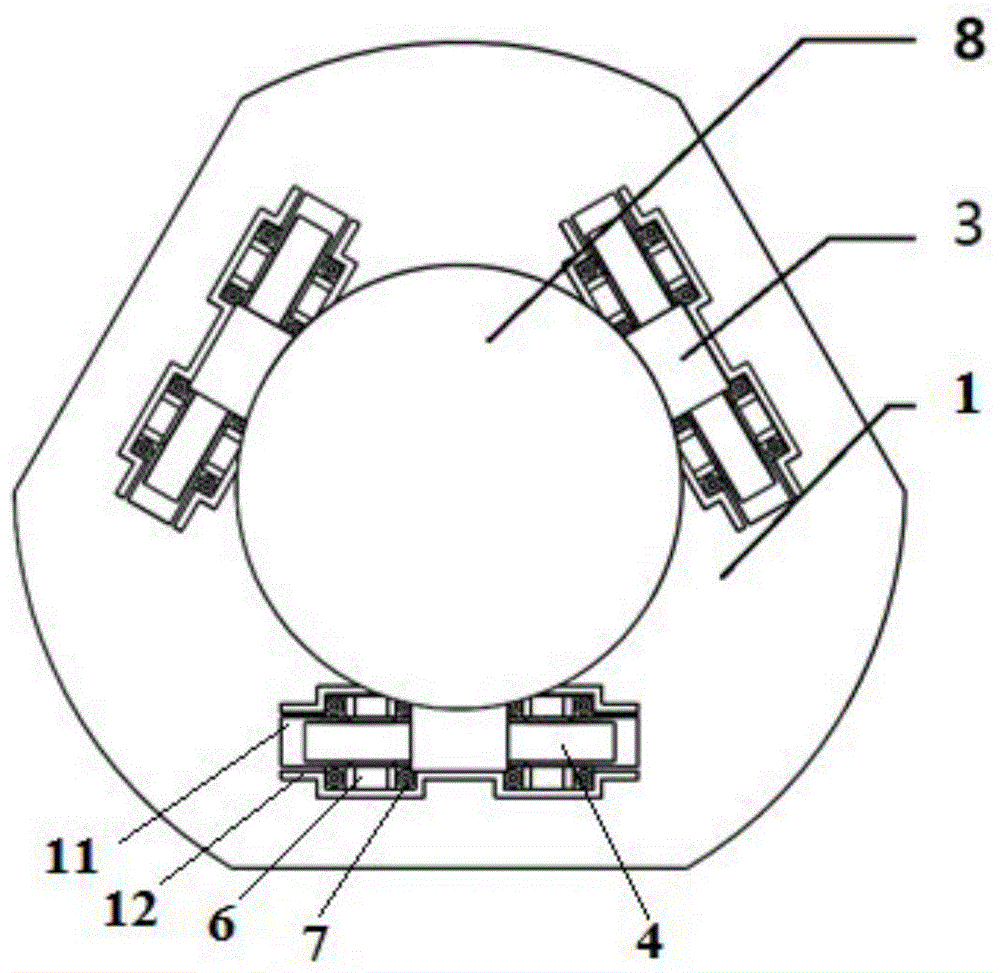

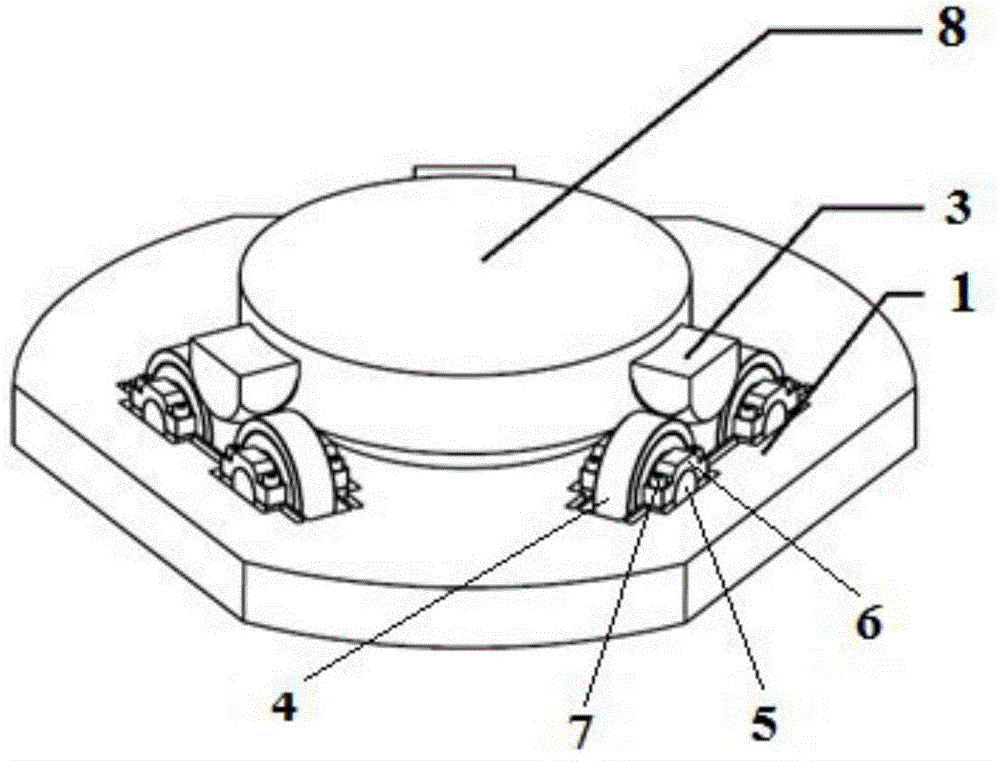

[0023] In order to make those skilled in the art understand the present invention further, below in conjunction with appendix Figure 1-8 The present invention is further described.

[0024] Such as Figure 2-8 As shown, the high-reproducibility optical element surface shape detection support device of the present invention includes a support plate 1 and a plurality of identical support units arranged on the support plate 1, wherein the support plate 1 is provided with a circular through hole 13 and At least three identical grooves 11; a circular through hole 13 is usually arranged in the central area of the support plate 1; It needs to be determined that three grooves 11 are generally used, and are preferably evenly distributed along the circumference of the circular through hole 13 at 120°; four identical flexible hinges 2 are arranged symmetrically and parallel on the two opposite surfaces of the groove 11, and Two flexible hinges 2 on each face of groove 11 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com