Chip type infrared emitter package

An infrared emitter and package technology, which is applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve problems such as uninstructed, and achieve the effect of reducing total heat loss and uniform infrared radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

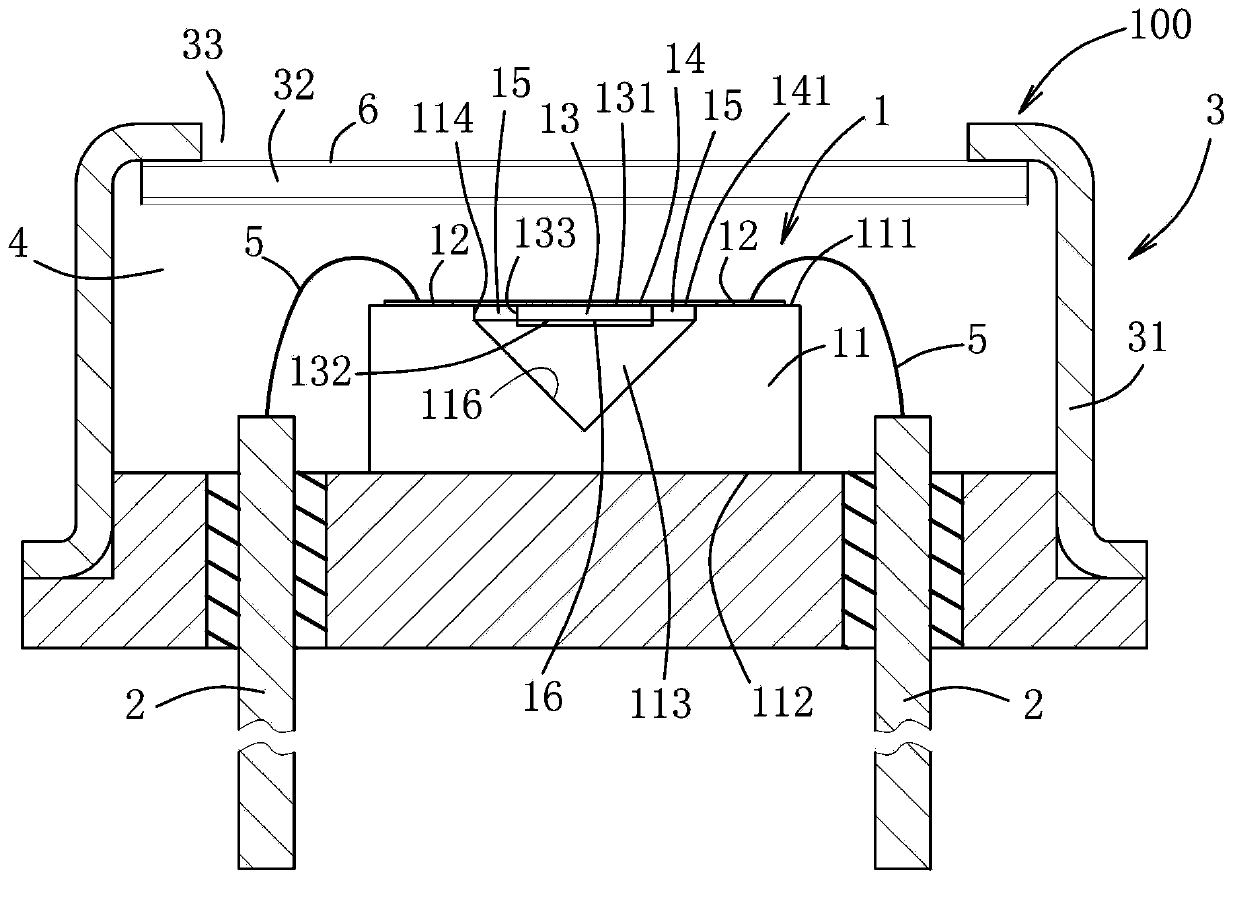

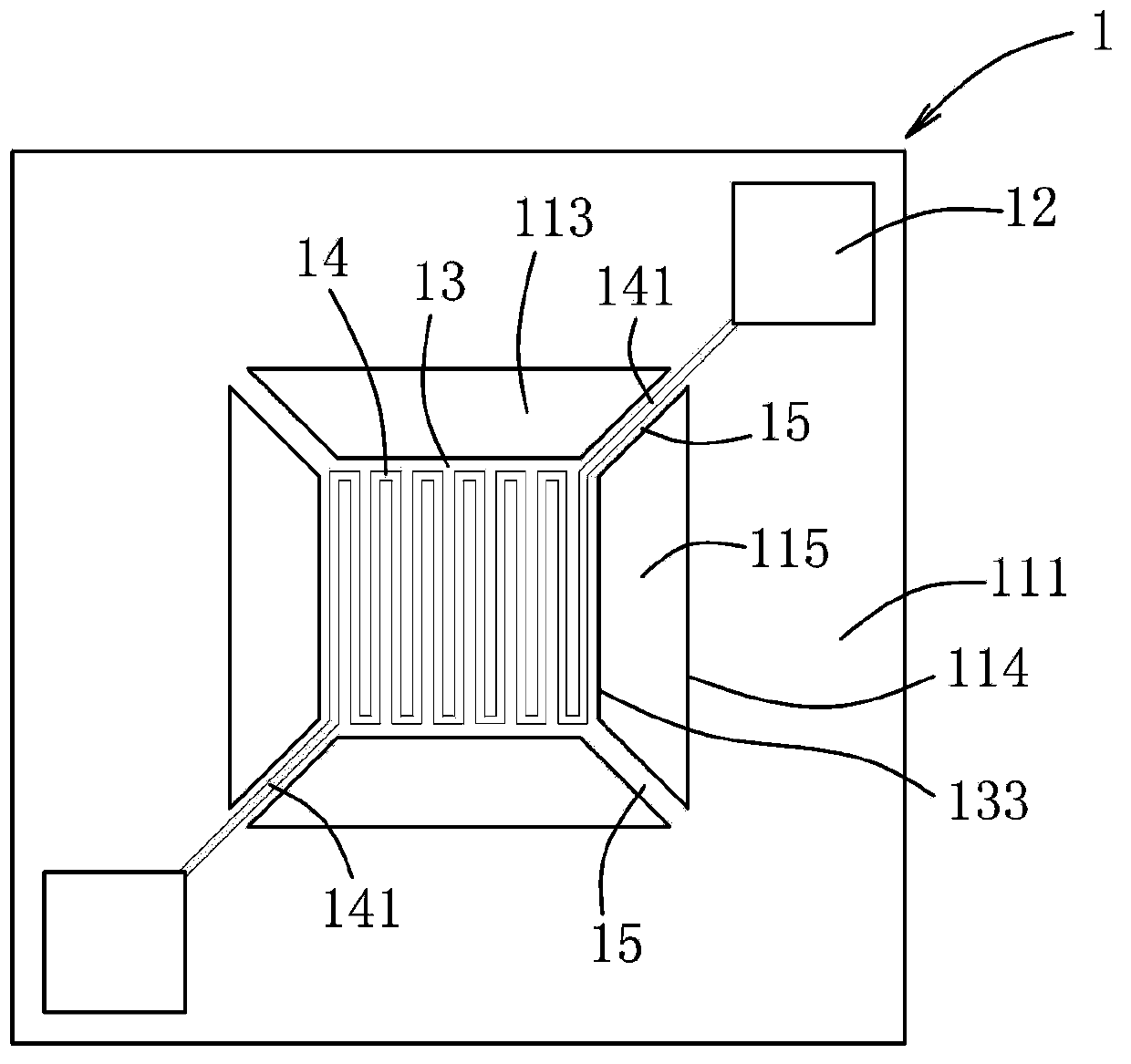

[0019] figure 1 and figure 2 The first preferred embodiment of the chip-type infrared emitter package 100 of the present invention is described.

[0020] The chip-type infrared emitter package 100 includes an emitter chip 1 , a pair of conductive leads 2 and a casing 3 . The transmitter chip 1 includes: a base 11, the base 11 has a top surface 111, a bottom surface 112 and a central cavity 113 extending through the top surface 111, the top surface 111 and the bottom surface 112 are in a Set oppositely in the vertical direction, the central cavity 113 is defined by a cavity defining wall 116, the cavity defining wall 116 has a bottom, and is arranged above the bottom surface 112 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com