A drying device with intelligent temperature control

A technology of drying device and programming controller, applied in drying, drying machine, heating device and other directions, can solve the problems of low efficiency and low degree of intelligence, achieve good drying effect, improve the degree of intelligence, infrared radiation uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that the plate-shaped food here refers to a plate-shaped food with a relatively regular shape such as biscuit and bread.

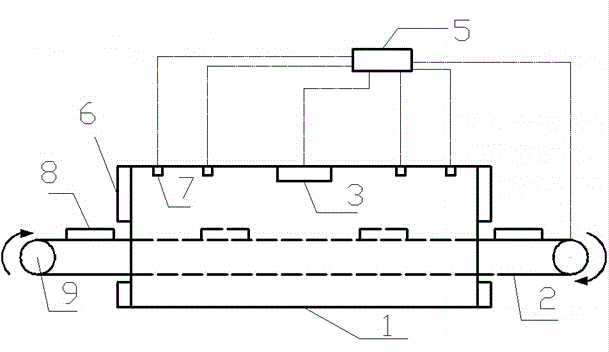

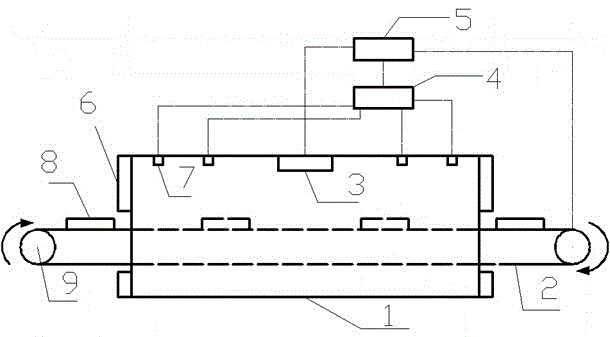

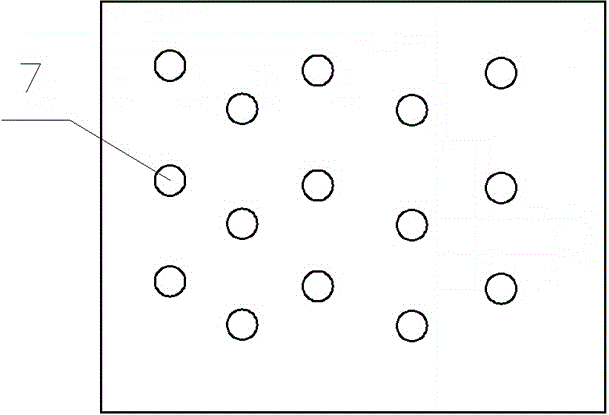

[0035] Such as figure 1 As shown, a drying device for plate-shaped food 8 includes a tunnel kiln 1, a heating part 3, a temperature sensor 7, a programmable controller 5, and a conveyor belt 2. The conveyor belt 2 passes through the tunnel kiln 1, and the heating part 3 and the temperature sensor 7 are arranged in the tunnel furnace, and the heating part 3 and the temperature sensor 7 are connected to the programmable controller 5.

[0036] Preferably, the heating component 3 is an infrared heating component, such as Figure 5 Shown. The infrared heating component includes a housing 11, an infrared radiating plate 12, an infrared heating element, and a heat insulating component 13. The bottom of the housing 11 is provided with a heat insulating component 13 connected to the bottom of the housing, and the upper part of the housing 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com