Inner sliding pipe support system and manufacturing method thereof

A technology of inner sliding and inner pipe, which is applied in the direction of pipe support, pipe protection, and heat insulation protection of pipes, etc. It can solve the problems of heat insulation, compression resistance, unsatisfactory bending resistance, bulky pipe support, poor relaxation design, etc. , to achieve the effect of optimized construction technology, simple structure, economical combination and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

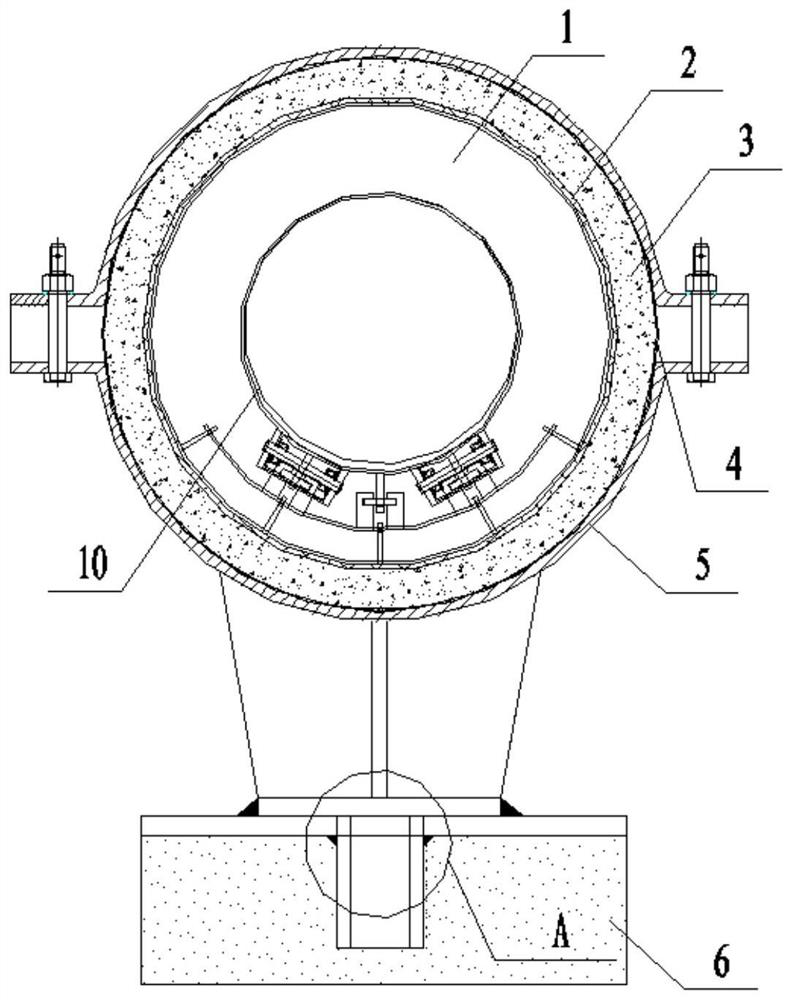

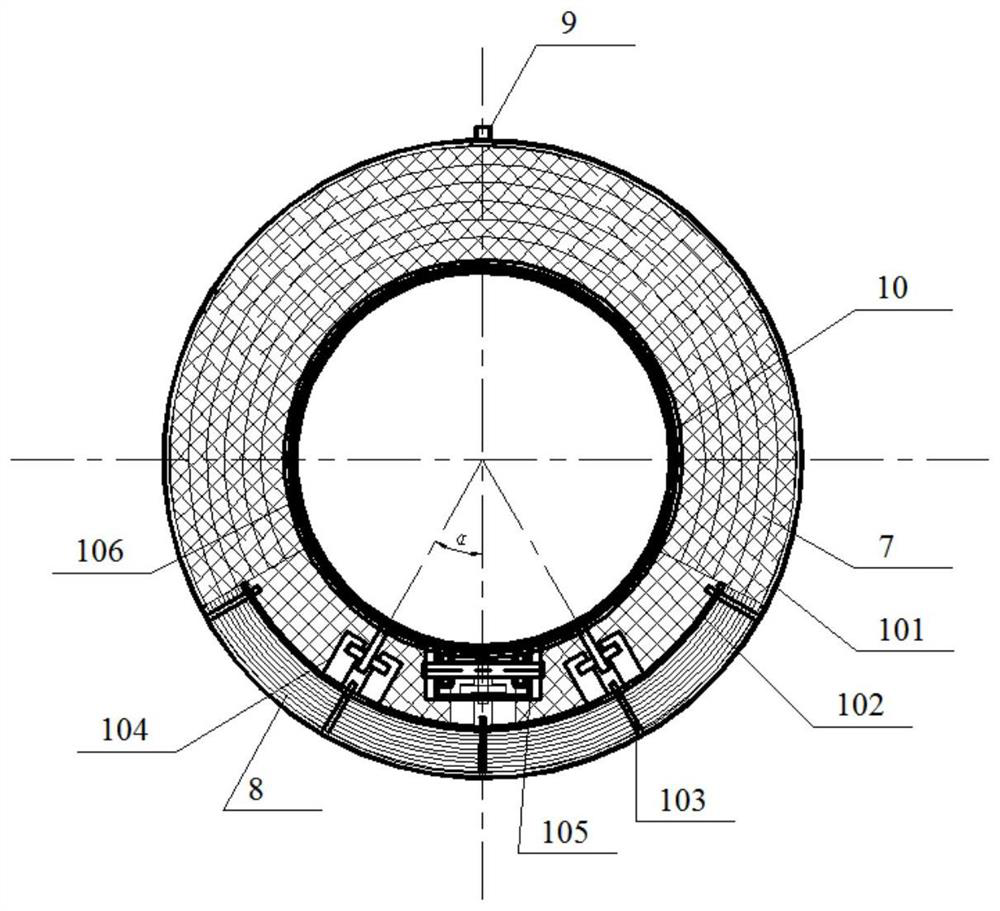

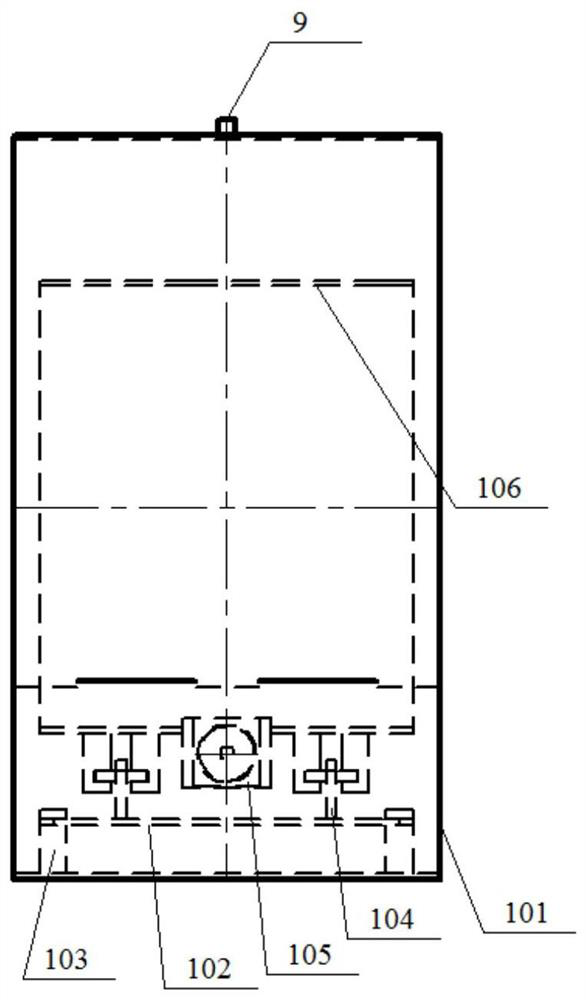

[0082] like Figure 1-26 As shown, an inner sliding pipe holder system includes an inner pipe holder 1 wrapped on the outer wall of a working steel pipe 10 from the inside to the outside, an intermediate sleeve 2, an outer sleeve 4 and an outer pipe holder 5, and is arranged on the intermediate sleeve 2 and the polyurethane layer 3 between the outer casing 4; the inner tube holder 1 includes an inner support tube 106 and an outer support tube 101 that are set inside and outside, and an arc-shaped plate 102 arranged between the inner support tube 106 and the outer support tube 101 , a fixed plate I103, a support assembly 104 and a roller assembly 105, the arc-shaped plate 102 is fixed between the inner support tube 106 and the outer support tube 101 by several fixed plates I103, and one end of the fixed plate I103 is fixed on the outer support The inner wall of the tube 101, the other end of the fixed plate I103 is fixed on the outer wall of the arc plate 102, one end of the su...

Embodiment 2

[0122] Example 2, such as Figure 1-26 As shown, using the inner sliding pipe support in the present invention, specifically, the diameter of the working steel pipe 10 is 720mm, the working temperature is 300°C, the ambient temperature is 20°C, and the composite thermal insulation structure layer 7 is made of aluminum silicate needle-punched blanket with a thickness of 40mm. and 160mm high temperature resistant glass wool, the thickness of the polyurethane layer 3 is 30mm, and the total insulation thickness is 240mm. The heat dissipation loss through the upper hoop 501 and the lower hoop 503 is calculated using the double-layer heat dissipation formula on the cylindrical surface. Similarly, through the vertical plate 504 1. The rib plate 505 is calculated by using the fin heat dissipation formula. Through calculation, the temperature of the inner layer of the polyurethane layer 3 is 79.6° C., and the heat dissipation loss of a single inner sliding tube support is 522.1w.

Embodiment 3

[0123] Example 3, such as Figure 1-26 As shown, using the inner sliding pipe support in the present invention, specifically, the diameter of the working steel pipe 10 is 720mm, the working temperature is 300°C, the ambient temperature is 20°C, and the composite thermal insulation structure layer 7 is made of aluminum silicate needle-punched blanket with a thickness of 40mm. and 120mm high temperature-resistant glass wool, the thickness of polyurethane layer 3 is 30mm, and the total insulation thickness is 210mm. The heat dissipation loss through the upper hoop 501 and the lower hoop 503 is calculated using the double-layer heat dissipation formula of the cylindrical surface. Similarly, through the vertical plate 504 1. The rib plate 505 is calculated by using the fin heat dissipation formula. Through the calculation, the temperature of the inner layer of the polyurethane layer 3 is 92.2°C, and the heat dissipation loss of a single inner sliding tube support is 626.7w.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com