A kind of electric fittings and aluminum silicon manganese alloy material used for casting the electric fittings

A technology of electric power fittings and matching connections, which is applied in the direction of electrical components, switchgear, etc., can solve problems such as the inability to provide strong reaction force, the service life cannot be guaranteed, and the main body of the fittings is broken, so as to reduce secondary pollution and improve service life , the effect of saving aluminum resources

Active Publication Date: 2016-03-23

STATE GRID CORP OF CHINA +2

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, the above-mentioned power fittings also have the following deficiencies, which are specifically manifested in: 1), fixed connection methods such as welding are adopted between the stud and the U-shaped draw-in groove, and this connection method is easy to break due to long-term stress

2) When the lead wire hook hooks the lead wire, because no anti-falling structure is adopted, when the lead wire is hung on the lead wire hook, it is easy to fall off.

3) The material of the above-mentioned electric power fittings is generally aluminum alloy, and the service life cannot be guaranteed. After 50 to 80 times of use, the main body of the fittings often breaks. Fittings cannot provide strong reaction force

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0038] The above-mentioned aluminum-silicon-manganese alloy material, the weight percentage is

[0039]

[0040] The balance is Al.

Embodiment 2

[0042] The above-mentioned aluminum-silicon-manganese alloy material, the weight percentage is

[0043]

[0044]

[0045] The balance is Al.

Embodiment 3

[0047] The above-mentioned aluminum-silicon-manganese alloy material, the weight percentage is

[0048]

[0049] The balance is Al.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

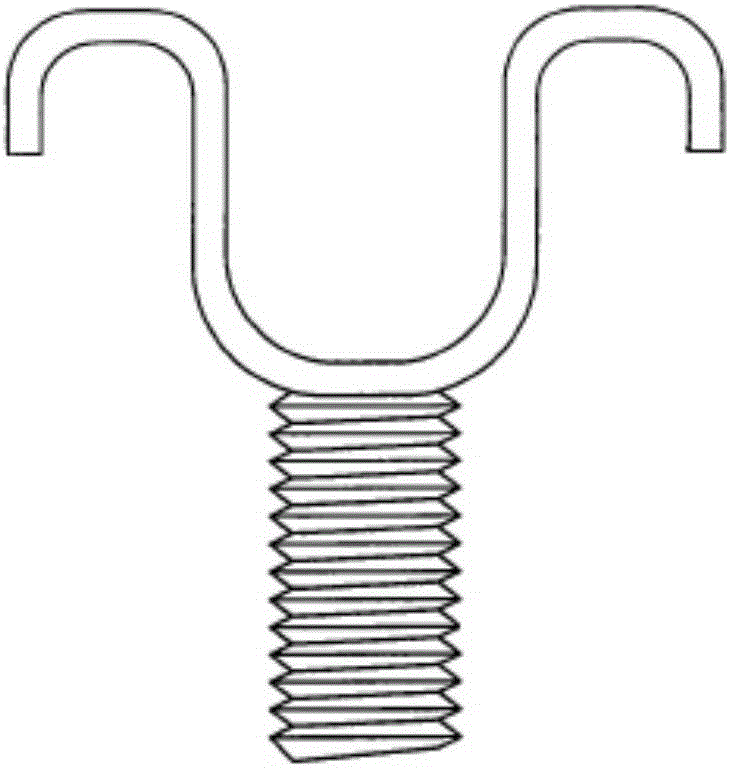

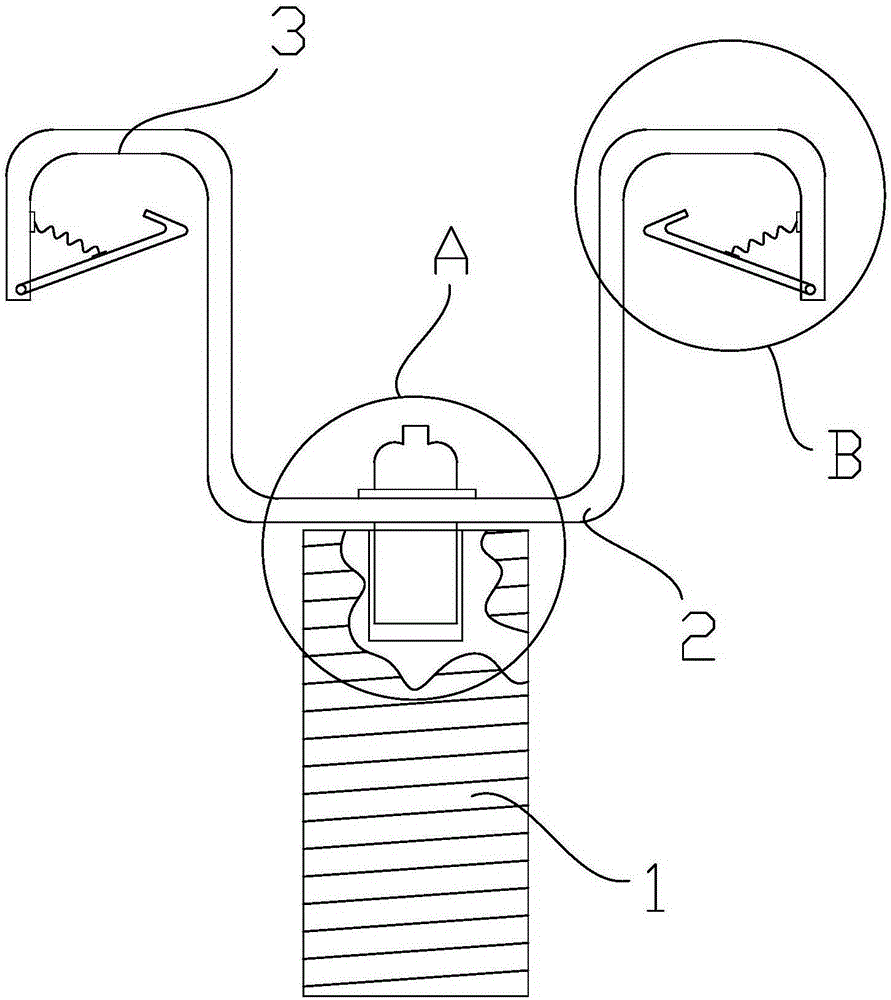

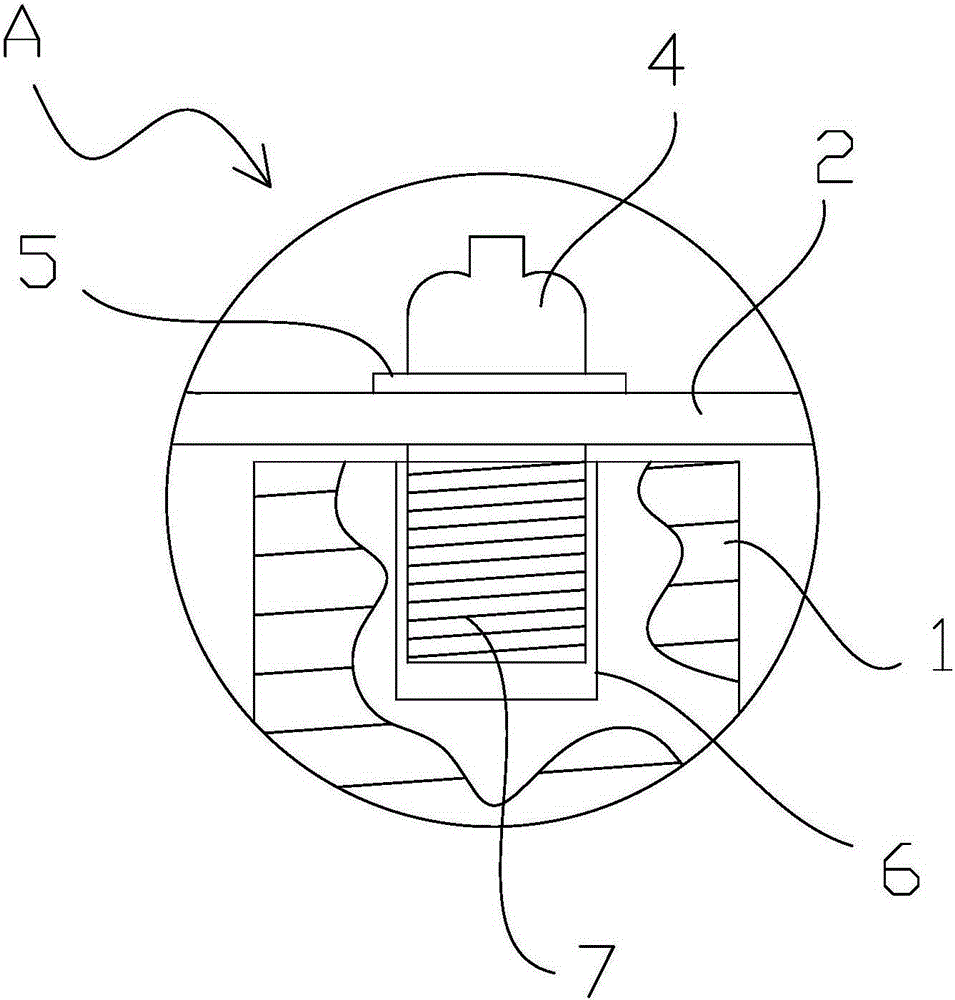

The invention belongs to the technical field of operating tools for electric power systems and casting of the tools, and particularly relates to an electric power fitting and an aluminum silicon manganese alloy material for casting the electric power fitting. The electric power fitting comprises a stud which is connected with an insulating rod in a matched mode, a U-shaped clamping groove is connected to the top of the stud, the two side edges of the U-shaped clamping grooves are bent downwards to form lead hooks, the stud is in running fit with the U-shaped clamping groove, and the U-shaped clamping groove rotates freely along the axis of the stud. According to the electric power system, due to the facts that that stud is designed to be in running fit with the U-shaped clamping groove and the U-shaped clamping groove rotates freely along the axis of the stud, the phenomenon of breakage caused by long-term stress resulting from the fixing and connection methods, such as welding, adopted between the stud and the U-shaped clamping groove is avoided. A moving contact of a disconnecting link can be embedded into the U-shaped clamping groove, so that the moving contact of the disconnecting link is protected aginast disengagement, the service life of the electric power fitting can be prolonged, and the application range of the electric power fitting is widened.

Description

technical field [0001] The invention relates to the technical field of an operating tool for an electric power system and the casting of the tool, in particular to an electric fitting and an aluminum-silicon-manganese alloy material used for casting the electric fitting. Background technique [0002] During the daily maintenance of the power system, it often happens that the knife switch is not closed or opened properly, and the on-site operators need to use the insulating rod to make fine adjustments. Due to certain defects in the design of the existing insulating rod, the insulating rod is prone to slip when it contacts the knife brake moving contact. At the same time, when dealing with the ground wire, it is necessary to hang the ground wire on the clamp. If it is hung on the middle wire of the lead wire, due to the existence of the lead wire sag, when the ground wire is removed, the load on the lead wire will lighten and rise accordingly, making the ground wire Not easy...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02B3/00C22C38/58

Inventor 程琳刘利华唐毅王华于传李标

Owner STATE GRID CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com