Double-air-chamber one-way airflow filter bag type dustproof respirator

A one-way airflow, double air chamber technology, applied in respiratory protection devices, protective clothing, clothing and other directions, can solve the problems of increased breathing resistance, decreased filtration efficiency, difficulty in breathing, etc., to achieve small breathing resistance, low cost of use, and appearance beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

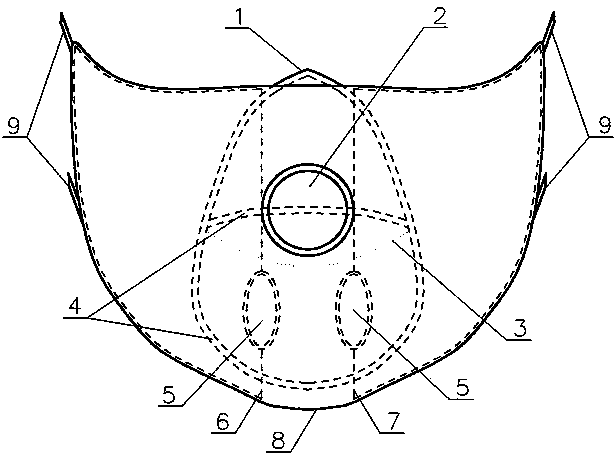

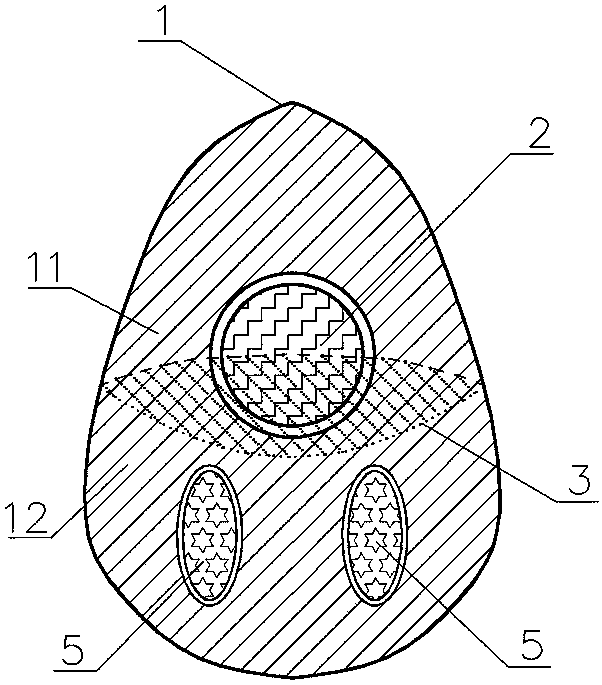

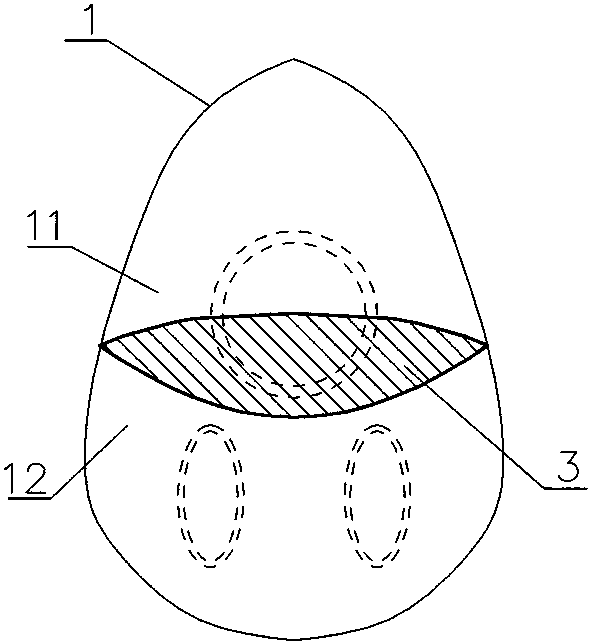

[0015] as the picture shows, one A double-chamber one-way airflow filter bag dust-proof respirator, the double-chamber main body mask 1 is equipped with an exhalation valve 2, a sealing gasket 4 and an inhalation valve 5, and the inhalation valve 5 is respectively connected to the filter bag mouth 61 and the filter bag The mouth 71 forms an assembly, and the assembly is packed into the overcoat 8 equipped with a headband 9 to form a complete dust-proof respirator. By fastening the headband 9, the dust-proof respirator is close to the face of the person.

[0016] Inhalation process of the present invention: people open their mouths to inhale, and the external air enters the filter bag after being filtered by the filter elements of the filter bag 6 and filter bag 7 through the jacket 8, and the filtered air passes through the filter bag mouth 61 and the filter bag mouth 71 The connected suction valve 5 enters the lower air chamber 12, and the air in the lower air chamber 12 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com