Production process for color steel tile

A production process and technology of color steel tiles, which are applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problem of affecting the production progress of wear-resistant steel balls, the loss of wear-resistant steel ball factories, and the increase of wear-resistant Problems such as the production cost of steel ball factories can achieve the effect of improving the quality of electrostatic spraying, increasing the service life and avoiding easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

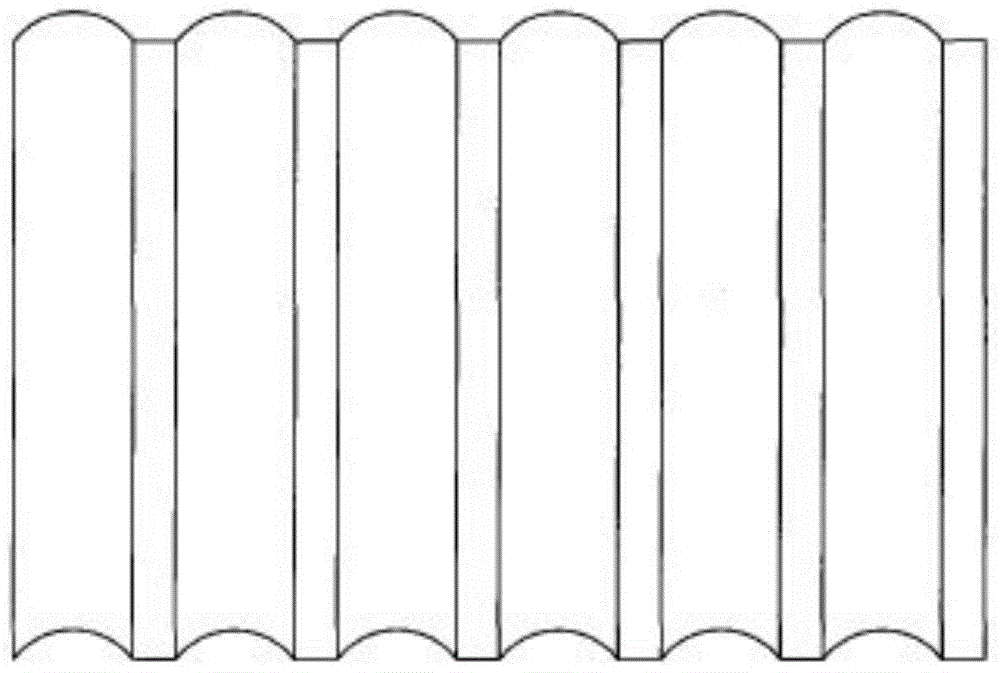

[0017] A production process of color steel tiles mainly includes the following steps: taking a steel plate with a thickness of 0.8mm and extruding it into such as figure 1 The shape shown; the formed color steel tile is cleaned through the nozzle to remove dust, oil stains and other dirt on the surface of the color steel tile; the color steel tile after spraying and decontamination is dried at a drying temperature of 200°C to remove surface moisture ; Send the color steel tile to the spraying workshop to spray paint powder while it is hot; put the profile into the curing workshop for curing, and the curing temperature is 200°C; when the cured profile is cooled to room temperature, check the film-forming quality of the color steel tile, Eliminate the color steel tiles with defective electrostatic spraying; put the qualified color steel tiles into the ventilated warehouse and prepare for delivery.

Embodiment 2

[0019] A production process of color steel tiles mainly includes the following steps: taking a steel plate with a thickness of 1.6 mm and extruding it into such as figure 1 The shape shown; the formed color steel tile is cleaned through the nozzle to remove dust, oil stains and other dirt on the surface of the color steel tile; the color steel tile after spraying and decontamination is dried at a drying temperature of 300°C to remove surface moisture ; Send the color steel tile to the spraying workshop to spray paint powder while it is hot; put the profile into the curing workshop for curing, and the curing temperature is 210°C; when the cured profile cools to room temperature, check the film-forming quality of the color steel tile, Eliminate the color steel tiles with defective electrostatic spraying; put the qualified color steel tiles into the ventilated warehouse and prepare for delivery.

Embodiment 3

[0021] A production process of color steel tiles mainly includes the following steps: taking a steel plate with a thickness of 2.0mm and extruding it into such as figure 1 The shape shown; the formed color steel tile is cleaned through the nozzle to remove dust, oil stains and other dirt on the surface of the color steel tile; the color steel tile after spraying and decontamination is dried at a drying temperature of 350°C to remove surface moisture ; Send the color steel tile to the spraying workshop to spray paint powder while it is hot; put the profile into the curing workshop for curing, and the curing temperature is 230°C; when the cured profile cools to room temperature, check the film-forming quality of the color steel tile, Eliminate the color steel tiles with defective electrostatic spraying; put the qualified color steel tiles into the ventilated warehouse and prepare for delivery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com