A kind of carbon nanotube-alumina composite material and preparation method thereof

A carbon nanotube and composite material technology, applied in the field of materials, can solve the problems of poor toughness and restrict the expansion of application fields, and achieve the effects of continuous performance, improved fracture toughness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

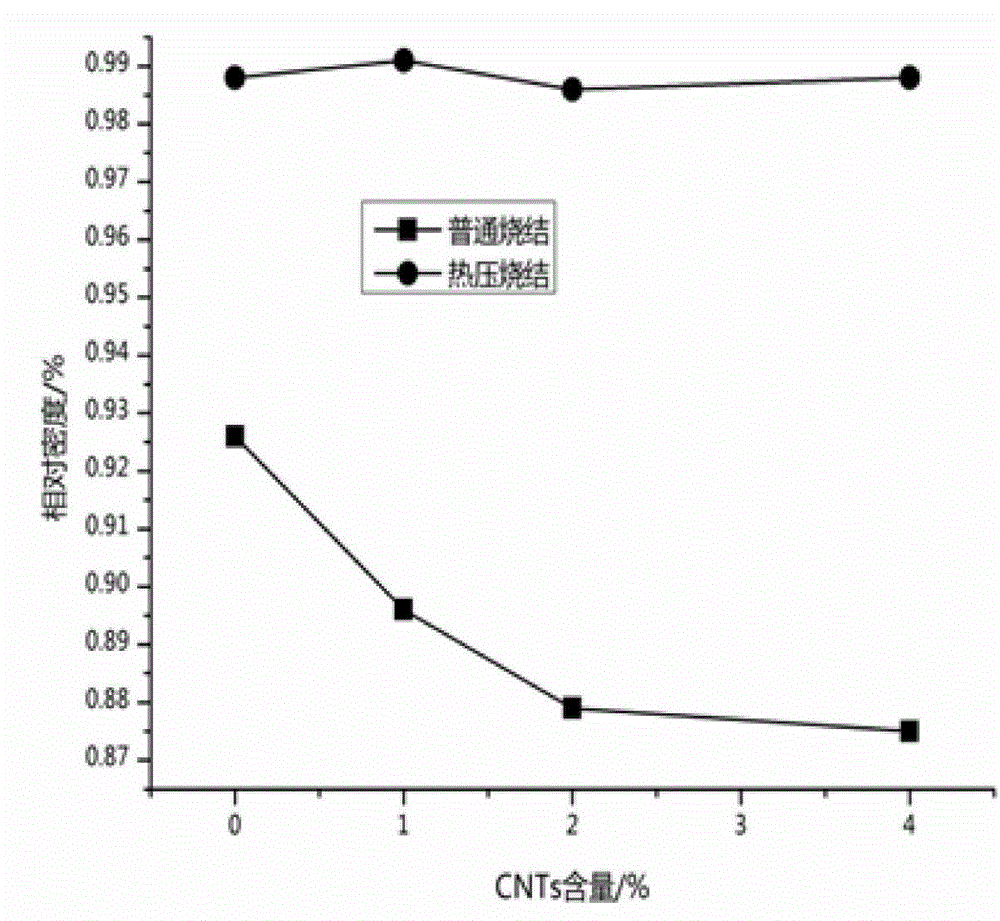

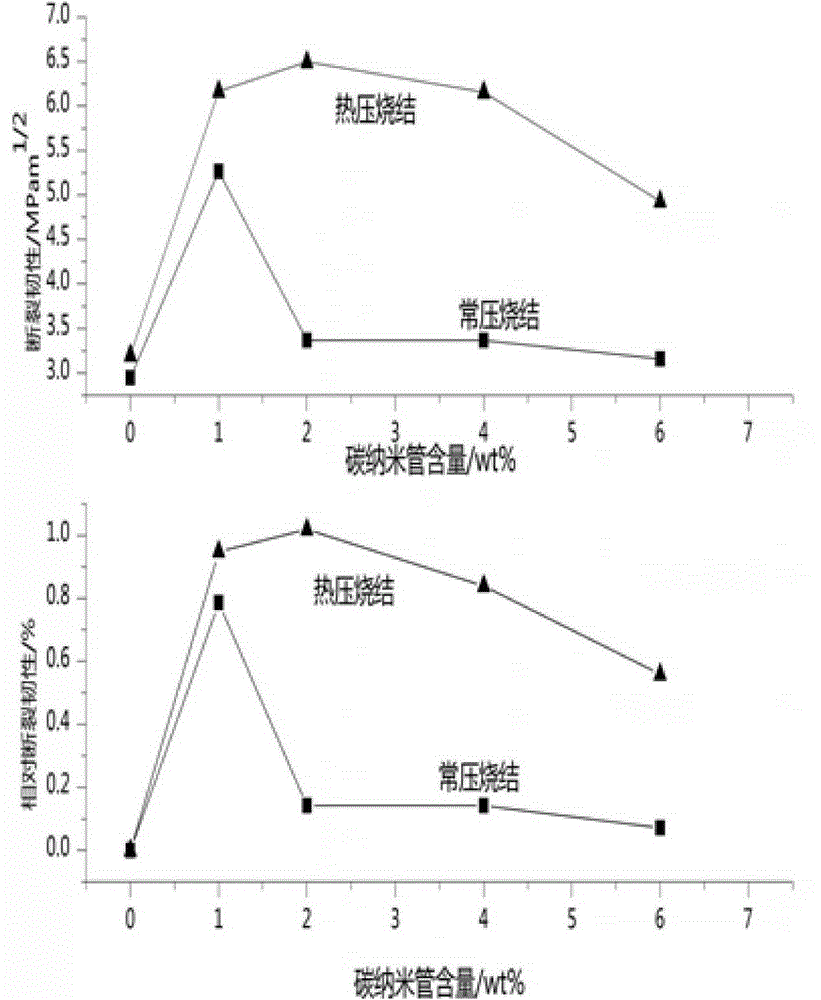

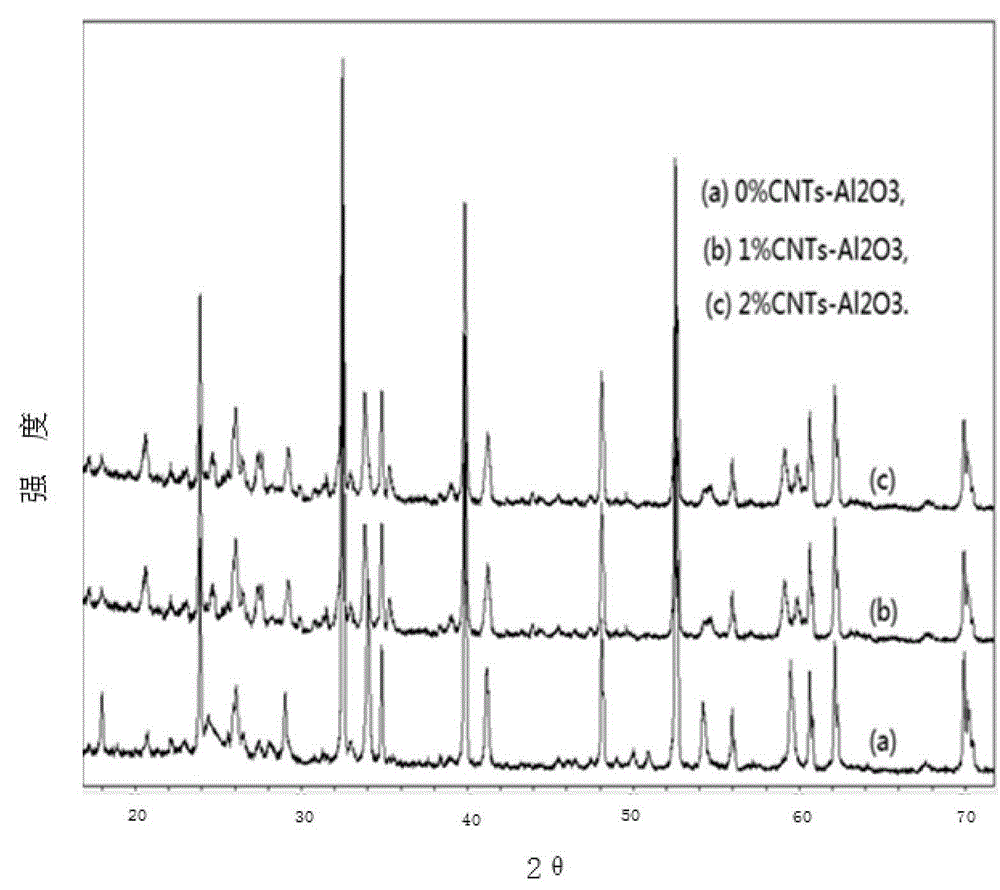

[0028] The carbon nanotube-alumina composite material of the present invention is composed of carbon nanotubes and alumina; wherein the weight percentage of the carbon nanotubes is 1%.

[0029] The specific steps of the method for preparing the carbon nanotube-alumina composite material of the present invention are as follows:

[0030] (1) First, prepare carbon nanotube-alumina composite powder by shearing method according to the ratio; add carbon nanotube and alumina powder to the molten polyethylene melt and stir and mix; add the mixture to the twin-screw extruder Or extrude and disperse in a single-screw extruder until it is stable; degrease the extruded material at high temperature, and remove the polymer material to obtain a carbon nanotube-alumina composite powder.

[0031] (2) Then add the PVA solution that the mass concentration is 5% to the carbon nanotube-alumina composite powder, then stir evenly, the PVA solution addition is 6% of composite powder weight, then dry;...

Embodiment 2

[0035] The carbon nanotube-alumina composite material of the invention is composed of carbon nanotubes and alumina; wherein the weight percentage of the carbon nanotubes is 0.1%.

[0036] The specific steps of the method for preparing the carbon nanotube-alumina composite material of the present invention are as follows:

[0037] (1) First, prepare carbon nanotube-alumina composite powder by shearing method according to the ratio; add carbon nanotube and alumina powder into molten polyvinyl chloride and polyoxymethylene melt and stir and mix; add the mixture to double Extrude and disperse in a screw extruder or a single-screw extruder until it is stable; degrease the extruded material at high temperature, and remove the polymer material to obtain a carbon nanotube-alumina composite powder.

[0038] (2) Then add the PVA solution that the mass concentration is 5% to the carbon nanotube-alumina composite powder, then stir evenly, the PVA solution addition is 2% of composite powde...

Embodiment 3

[0042] The carbon nanotube-alumina composite material of the present invention is composed of carbon nanotubes and alumina; wherein the weight percentage of the carbon nanotubes is 6%.

[0043] The specific steps of the method for preparing the carbon nanotube-alumina composite material of the present invention are as follows:

[0044] (1) First, prepare carbon nanotube-alumina composite powder by shearing method according to the proportion; add carbon nanotube and alumina powder into the molten paraffin melt and stir and mix according to the proportion; add the mixture to the twin-screw extruder extruder or single-screw extruder until the dispersion is stable; degrease the extruded material at high temperature, and remove the polymer material to obtain carbon nanotube-alumina composite powder.

[0045] (2) Then add the PVA solution that the mass concentration is 5% to the carbon nanotube-alumina composite powder, then stir evenly, the PVA solution addition is 10% of composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com